REFUSE-DERIVED FUELS (RDF) AND CEMENT KILNS

While RDF is not actually a form of chemical recycling, it is a form of plastic to fuel and has therefore been included at this point for comparative purposes.

Numerous terms have emerged to describe this ’product’, which is a repackaged, blended, or ‘engineered’ fuel made from plastic waste mixed with other elements of commercial, industrial, or municipal waste to be burned in cement kilns. Names include ‘Refuse-Derived Fuel’, ‘Alternative fuel’, ‘Process Engineered Fuel’, ’Secondary fuels’, ‘Substitute Fuels, ‘Solid Recovered Fuels’, Climafuel®, and so on. For convenience, they will hereafter be referred to as ‘RDF’.

According to The World Business Council for Sustainable Development these materials are:

“Selected waste and by-products with recoverable calorific value (that) can be used as fuels in a cement kiln, replacing a portion of conventional fossil fuels, like coal, if they meet strict specifications. Sometimes they can only be used after pre-processing to provide ‘tailor-made’ fuels for the cement process.”

In reality, they are simply plastic waste, and municipal, commercial, and industrial waste processed and shaped into units based on calorific content for industry to burn. In other words, they are simply repackaged wastes and fossil fuels at an intermediary stage before combustion. Their combustion releases are similar to, if not identical to the toxic emissions, particulate, and climate change gases as they would be if burned in their ‘loose mixed waste’ form. The combustion of these products is not limited to cement kilns (though they consume the majority of such ‘fuels’), but it is also burned in waste incinerators and some other specialized, boiler-based production industries.

The ‘ingredients’ of RDF generally consist of dry recyclable materials including:

· Timber

· Plastic

· Cardboard

· Paper

· Textiles

· MSW

The production of RDF usually involves reception of mixed waste which is subject to:

· Bag splitting/Shredding

· Size screening

· Magnetic separation

· Air classifier (density separation)

· Coarse shredding

· Refining separation by infrared separation

· Calorific content assessment

· Baling

· Pelletizing

The processing of waste into RDF is usually designed to remove inorganic materials (glass, metals, sand, stone, moist organics) and any other materials that inhibit combustion, and distribute the various waste streams within the finished product to homogenize the calorific content of the bale or pellets.

Figure 23. Baling and loading RDF in Ireland bound for Landskrona Energi Swedish Incinerator.

Figure 24. RDF pellets.

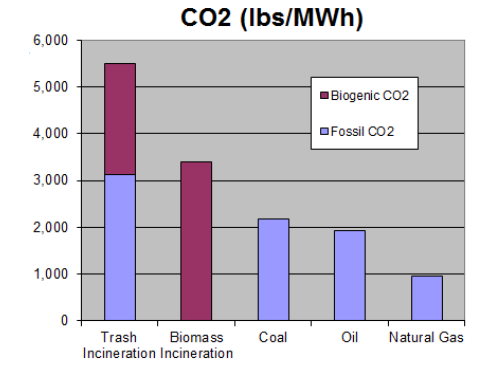

Proponents of RDF argue that it results in a net reduction of greenhouse gas (GHG) emissions from the cement kiln or incinerator as the RDF displaces fossil fuel. Typically, these arguments are based on comparisons to the waste being sent to landfill followed by high methane emissions (a potent GHG) instead of being processed to RDF. They never compare the results to the use of renewable energy to offset the fossil fuels as the results of RDF compare poorly. Burning mixed waste for energy as RDF in cement kilns or in waste incinerators, has the highest global warming potential per unit of energy generated compared even to other fossil fuels (see Figure 25), let alone renewables such as solar or wind power.

The difference between burning waste or burning RDF in cement kilns is largely a matter of semantics worth millions of dollars to the producers of RDF and the cement kilns who use it. The contortions of language involved in trying to pretend that RDF (and its namesakes) are anything but waste came to light recently when the Philippines investigated RDF shipments from ResourceCo in Australia to Holcim Cement in the Philippines.

With diplomatic tensions between Canada and the Philippines at breaking point over Canada’s failure to retrieve hundreds of illegally shipped waste containers (including threats of war), heightened scrutiny of shipping containers exposed shipments of waste classified as RDF from Australia.

The ensuing furore saw port officials questioning the labelling of the shipment,“The question is, are they the same? They insist it is. But I beg to disagree because garbage is garbage, fuel is fuel.” At a subsequent media briefing, Presidential Spokesperson Salvador Panelo said, “We will not allow ourselves to be dumping ground of trash.” Complicating the issue, the Environment Department said the shipment was legal because it was RDF bound for Holcim Philippines cement kilns.

The definitional arguments continue and are complicated by the Basel Convention and the newly operational Basel Ban Amendment which prohibits member states of the OECD and the European Union and Liechtenstein (Annex VII countries) from shipping hazardous waste, as defined by the treaty, to non-Annex VII countries—generally countries with low to medium income that cannot manage such wastes in an environmentally sound manner. Under certain conditions, the Basel Convention allows the country of import to determine whether a shipment of certain material is considered a ‘hazardous’ waste, and to reject the shipment. This would depend on the contents and concentration of materials that may be hazardous within the RDF or PEF.

The rise of RDF is attributable to its profitable nature. Not only can the producer of RDF charge industry and local government for the waste it receives, they can also charge the recipient of the RDF (e.g. cement kilns). Along the way, they can also profit from the monetary value of the biomass fraction of the RDF under various greenhouse gas protocols, such as the European Union Emissions Trading Scheme35, the UK Renewable

Figure 25. CO2 emissions of burning waste compared to other fuels per MWh

Obligation Certificate36, and the Australian Emissions Reduction Fund.37 The biomass fraction such as paper, cardboard, and wood are considered to generate renewable energy, although studies have effectively debunked this carbon accounting proposition .

In their search for high calorific value fuels, cement kilns still have to limit their use of waste plastics due to the corrosive effects of the thermal degradation products. Hahladakis et al. (2018) note, ”Halogens emitted from the combustion of plastic waste can also cause corrosion in incinerators and other thermal facilities. Chlorine and bromine may accumulate in cement kiln systems limiting their capacity for thermal recovery of plastic.”

Of more concern for the environment and human health are the implications of the cement kilns not operating to BAT BEP standards when using halogenated (bromine, chlorine, fluorine) plastic as fuel. “However, uncontrolled combustion of plastic waste and, in particular of those containing halogens such as, PVC, polytetrafluorethylene/teflon, plastic containing brominated flame retardants, etc. can cause emissions of hazardous substances, e.g. acid gases and unintentional persistent organic pollutants (POPs) such as dioxins” .

Cement kilns burning traditional fossil fuels have less risk of these types of toxic emissions, but including mixed plastic waste rebranded as RDF only increases these risks – particular for countries who do not have the emission monitoring, enforcement, and monitoring provisions required to operate cement kilns to European BAT BEP standards.

In conclusion, RDF is simply rebranding of waste as a product to attract climate mitigation subsidies at the expense of real renewable energy, avoid waste trade restrictions, and make a profit from transferring the waste burden of wealthy countries to those countries least able to manage it.