Thermal depolymerization (pyrolysis and gasification)

The output of plastic pyrolysis and gasification cannot (with a couple of exceptions25) be used directly to produce polymers. The outputs are char, oil, tars, and gas with mixed hydrocarbon molecules containing a range of contaminants, which must be subject to much the same processes and refinement as crude oil requires before it can be developed into polymers. Therefore, these processes essentially generate raw hydrocarbon feedstock to manufacture polymers, rather than monomers or polymers directly. However, as mentioned previously, economic issues generally result in these raw hydrocarbons being sold and burned as a form of reconstituted fossil fuel made from plastic waste rather than being used as a new polymer or petrochemical feedstock.

Petrochemical and plastic corporations claim these technologies will take mixed plastic waste inputs with significant levels of contamination and produce new, clean feedstock for polymer production. The condensation on the syngas allows for separation of contaminants from the target outputs and concentrates them in the process residue. However, in reality syngas use in gas turbines has been restricted by contaminant levels in the past including halogens, fine particulates, sulfur, ammonia, chlorides, mercury, and other trace heavy metals.

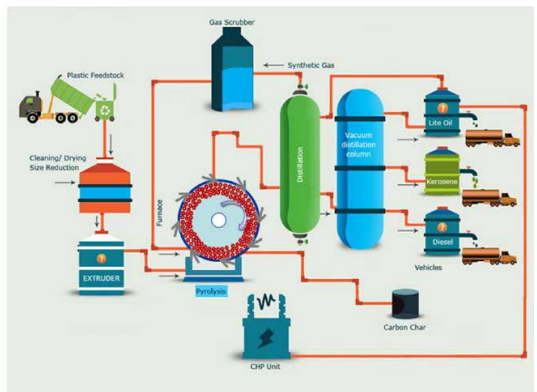

Figure 17. Plastic pyrolysis plant scheme with vortex reactor.

Pyrolysis and gasification technologies have been around for decades, and have often been proposed as a technique for generating surplus ‘green’ energy from mixed municipal waste. Most commercial sized operations have failed to deliver commercially economic energy supplies. In Germany, the realization that this technology could not deliver excess energy beyond its parasitic loads cost the state dearly (Gleis 2012) after massive state investment in gasification of municipal waste for energy was lost due to facility failures and closure.

Industrial-scale pyrolysis has failed in the past, but new start-ups are reconfiguring the technology, which is still hampered by high energy consumption, up to 5-20% of the calorific value of the waste input. Mixed-plastic inputs to pyrolysis processes also have a significant potential for development of toxic polyaromatic hydrocarbons (PAHs) and dioxins. The most significant concern about scaling up pyrolysis is that

“there is significant uncertainty about whether building a pyrolysis infrastructure to recycle plastics will actually lead to new materials, or only to fuels. Such a linear lock-in is clearly not in line with the basic principles of a circular economy and is one of the major concerns when considering the role of pyrolysis in the plastics economy”.

The basic principal behind the waste-to-energy version of these technologies is to heat waste in enclosed chambers in either no-oxygen (pyrolysis) or low-oxygen (gasification) environments to produce syngas (synthetic gas), which can then be burned to generate steam for electricity generating turbines. The key factor in commercial failure is an inability to generate surplus energy due to high external energy input required to heat the waste to pyrolytic temperatures. When energy consumption is calculated for the pre-sorting and drying of waste, the energy mass balance of pyrolysis is very poor.

Rollinson and Oladejo note in their seminal 2019 paper on the commercial failure of pyrolysis and gasification to generate meaningful energy balances from municipal waste that:

“Using literature review and case study methods, along with civil permit applications and experimental results, it shows that a pyrolysis plant for self-sustaining Energy from Waste is thermodynamically unproven, practically implausible, and environmentally unsound. A linkage between widespread commercial failures and a lack of focus on thermodynamic fundamentals is also identified, along with an environment of indifference or ignorance towards energy balances and sustainability when these technologies are presented, assessed and financed. The situation presents a high risk to investors and has the potential to adversely impact on societal transitions to a more sustainable future.”

Rollinson’s criticism regards the high energy input and poor energy production characteristics of pyrolysis and gasification processing municipal solid waste (MSW) – including plastics – at anything other than small batch reactor scale. Thermal depolymerization of plastic by pyrolysis and gasification shares many of the shortcomings of the MSW processes, but also has differing outputs and objectives to MSW processing. When discussing plastic to fuel variations of ‘depolymerization’, i.e. when the output is to be combusted rather than recycled, Rollinson’s criticisms can be applied more directly. This section addresses ‘depolymerization to plastic’ first and then ‘depolymerization to fuel’ in order to highlight these issues.