WHAT PLASTIC ACTUALLY GETS RECYCLED AND WHAT DOES NOT?

The answer depends, to some degree, on which country you live in. As noted in the previous section, low-income countries lack the developed infrastructure to recycle even the most easily recycled polymers. Much of the plastic waste ends up in the environment, burned or choking waterways, and contaminating the ocean. In wealthy countries with adequate waste management infrastructure, it is possible for more plastic waste to be recycled, however market conditions currently ensure that large amounts of plastic waste are incinerated, landfilled, or exported. The issue is usually not what can technically be recycled but what can economically be recycled. Most plastics that are labelled as recyclable with a triangular circulating arrow with a resin code number in the center (see Figure 14) are not

Figure 11. Smoke from plastic-burning tofu factories in Tropodo, Indonesia.

Figure 12. Informal recycling of plastic waste. Bangun, Indonesia.

economically recyclable and become waste. The most recycled polymers are PET (RC 1) and HDPE (RC 2). Polymers such as PVC (RC 3) and polypropylene (RC 5) are generally not accepted for recycling. Polystyrene (RC 6) also has low recycling rates. These resin codes and the recycling symbol that surrounds them were developed by The Society of the Plastics Industry (SPI) at a time when regulatory bans on some types of plastic were gaining traction. They were designed to focus consumers on the issue of recycling and not on the issue of environmental impacts of plastics. However, within the plastic industry, recycling was not considered viable, and research suggests the SPI did not believe that recycling could be economically viable.

The plastics industry has long used the resin codes in the recycling symbol to convince consumers that plastic is recyclable. The reality is that this is a misleading marketing ploy to avoid plastic bans. While many polymers can technically be recycled under laboratory conditions, the reality is that the economics of commercial scale recycling don’t add up. A key constraint is the ability of recyclate to compete with virgin polymer in the marketplace. When the price of oil, the petrochemical building block of plastic, is low recyclate cannot compete. Even if it could, the market for recycled plastics is weak due to concerns about the functionality of recycled polymer compared to virgin polymer. Despite these barriers some plastic is recycled or downcycled into new uses.

The preferred plastic waste for recyclers is post-industrial (PI) plastic waste such as runners from injection moulding, waste from production changeovers, cuttings and trimmings as they are relatively contamination free and often occurs as polymer ‘mono-streams’, which are uncontaminated by other polymers and have not been subject to degradation through use and wear .

Clean, post-consumer plastic waste is the next preferred input to recycling, but in reality, most post-consumer plastic waste is mixed polymer with varying degrees of contamination, both by organic waste and other polymers. By far, the largest fraction of plastic waste is from packaging (which also has the largest share of production), and it is dominated by the five biggest global production volume plastics; (high density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP) and polyethylene terephthalate (PET), and poly vinyl chloride (PVC).

In theory, most plastics are recyclable. But as explained in the sections below, there are many technical and economic barriers to recycling plastics, including energy use, contamination, toxic additives, and laminated constructions. However, potentially recyclable polymers are identified in Figure 14 by recycling symbols developed by the Society of the Plastics Industry (SPI) in 1988. In reality, only RC codes 1 and 2 are commonly recycled. While other RC polymers may be technically recyclable in a laboratory a range of reasons, including economics, mitigates their ability to be recycled in a viable way.

Generally, the lower the resin code (RC) number, the more likely it is to be recycled. In reality this translates to PET and HDPE. The higher the RC code the less likely the plastic is to be recycled due to economic or environmental reasons. Polystyrene (RC 6) takes both a rigid form (yoghurt containers, plastic cutlery, and CD cases) and a foam. Expanded polystyrene (EPS) foam is used for coffee cups, fridge insulation and packaging of electronic goods. This is different from Styrofoam™ which is a closedcell extruded polystyrene (XPS) used in building insulation. A significant fraction of existing XPS contains POPs BFRs to limit fire potential in buildings. While the Stockholm Convention exemption permitting the use of the BFR Hexabromocyclododecane (HBCD) in building insulation expired in 2019 (meaning it can no longer be added to XPS), the legacy of existing installed insulation will have to be managed for decades as buildings constructed in recent decades reach their end of life and are demolished in the future. RC 7 includes styrene acrylonitrile (SAN), acrylonitrile butadiene styrene (ABS), polycarbonate (PC), and nylon which are rarely recycled using mechanical processes.

A low RC does not necessarily make the polymer easy to recycle. As an example, plastic films, plastic wrapping, and thin plastic bags using low density polyethylene (RC4) often clog recycling process machinery when mixed with heavier plastics, resulting in low recycling rates for this polymer.

In terms of consumers goods, the following polymers are used for specific products, but only RC 1 and RC 2 are commonly recycled:

· Resin code 1: PET typically includes drink bottles, medical containers and cups. Recycled PET can become fiberfill for winter coats, sleeping bags, and life jackets.

· Resin code 2: HDPE is one of the most commonly recycled postconsumer plastics. It is the stiff plastic used to make milk containers, detergent and motor oil bottles, toys, and some plastic bags.

· Resin code 3: PVC includes rigid plastics like pipes and tubes but also food wraps, vegetable-oil bottles and blister packages, shower curtains, medical tubing, and car dashboards.

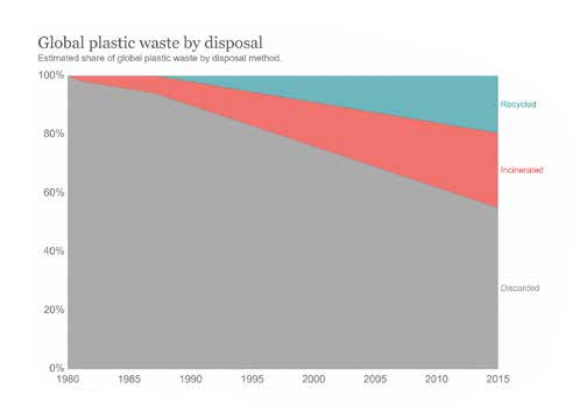

Figure 13. Global plastic waste recycled, incinerated or dumped 1980 – 2015.

· Resin code 4: LDPE is light weight, thin and flexible, and is commonly used for beer six-pack fasteners and plastic bags, including zip lock bags.

· Resin code 5: PP is used in food containers, some plastic car parts, and caps for bottles.

· Resin code 6: PS is used to hold food, drinks cups and some plastic utensils.

· Resin code 7: A general-purpose category for acrylic, nylon and other plastics.

Plastics that cannot legally be recycled or which are very difficult to recycle include:

· POPs-contaminated plastic18 (see section 5).

· Laminated plastics* (multiple-layered packaging including foil, polymer, and paper) such as snack packets and take-out coffee cups.

· Plastic films (agricultural silage wrap, cling film, etc.).

· Most items in RC 3, 4, 5 and 7.

· XPS with BFR additives*.

The following section challenges the assumption that chemical recycling is really the silver bullet for plastic pollution as suggested by the Fast-Moving Consumer Goods companies (FMCGC) and petrochemical corporations who are heavily promoting chemical recycling as a solution for plastic waste.