PLASTIC RECYCLING

As the pressure to deal with plastic waste grows daily, new technologies and concepts for plastic waste management arise apace. Many of these

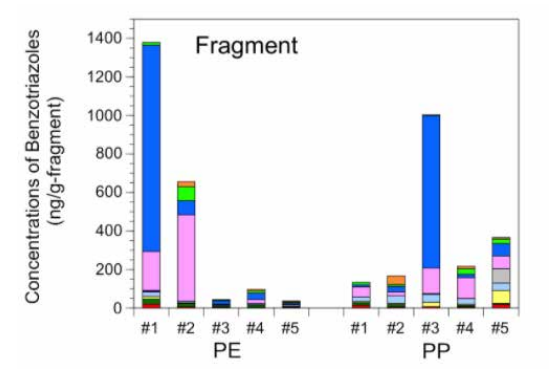

Figure 7. Benzotriazole (BT) UV stabilizers in 5 polyethylene and polypropylene fragments from remote coastal locations.

Figure 8. BT UV stabilizers in pellets samples from remote coastal locations.

so-called solutions lead to further contamination issues or simply do not work. Others seem completely at odds with a carbon-constrained future. Yet others seem to ignore the fact that many plastics contain toxic chemical additives and redirect these materials into inappropriate scenarios increasing human exposure. It is unlikely that the vast variability in plastic waste can be addressed by any single, silver bullet, technical solution. The reality is that multiple technical and social approaches will be needed, and they will all need to be assessed for their ability to operate with environmentally sound outcomes across a range of criteria. These would include toxic outputs and redistribution, carbon footprint, ability to contribute to a circular economy, and environmental justice (not dumping plastic waste on low-income countries and communities), among others.

Existing and emerging approaches to plastic waste management that some claim are solutions to the plastic waste problem include:

· Mechanical recycling

· Chemical recycling

· Downcycling (use in road surfacing, etc.)

· Plastic to fuel

· Plastic to energy (waste incineration)

· Reuse

· Landfill

This report focuses on mechanical and chemical recycling and associated plastic to fuel approaches. However, no meaningful comparison of these approaches can be made without acknowledging that many plastics are not benign in nature. Indeed, the Canadian government plans to list plastics as toxic under Schedule 1 of the Canadian Environmental Protection Act (CEPA) to allow them to ban certain uses of polymers.9 As noted above, in order to impart specific characteristics (color, pliability, durability, fire resistance, and so on) many polymers contain chemical additives that are toxic and hazardous. Large volumes of plastics are also infused with the extremely toxic group of chemicals known as persistent organic pollutants (POPs). These plastics should not be recycled at all and must be destroyed unless they can be decontaminated.

This means that a management approach that might suit a PET plastic water bottle may be completely inappropriate for a plastic dashboard from a car that contains a high percentage of POPs, like brominated flame retardants. Research demonstrates that many of these POPs-contaminated plastics ‘leak’ POPs into their environment while still in use, contaminating household dust, car interiors, and office spaces . Concentrating these plastics as waste into management facilities, processing technologies, and recycled products can lead to unintended and extremely hazardous workplaces, emissions, exposures, and products, as POPs can leach out and adsorb to dust in these settings . Options for the management of end-of-life POPs-contaminated plastics are described in more detail in section 5.

For decades, plastic recycling has almost entirely been dominated by the mechanical recycling sector which sorts, cleans, shreds, extrudes, and pelletizes polymers back into feedstock for the plastic manufacturing sector or supplies plastic recyclate for various forms of downcycling. Chemical recycling (for polymers or fuels) has been limited mostly to trials with a few pilot plants established. Supercritical water plants for specialized depolymerization have been operating for around 20 years.

Despite these efforts, plastic recycling has had a minimal impact on reducing environmental plastic pollution, and even less on substituting polymers and reducing overall virgin plastic production. When oil prices are low, it is extremely difficult for recycled plastic to compete with virgin materials. Estimates10 suggest global plastic recycling rates in 2015 were 19.5% compared with incineration rates of 25.5%, and 55% landfill/open dumping rates (Figure 13). Extrapolation of current trends to 2050 would see recycling rise to 44%, but incineration rise to 50% of all plastic produced in that year. Based on the forecast projection of production of plastic at 1 800 million tons for the year 2050 (Ryan 2015) and extrapolation of disposal methods on current trends (Geyer 2017) approximately 900 million tons of plastic will be incinerated in the same year. These figures infer that incineration will mostly replace landfilling and open burning, which will be reduced to 6% of all plastic produced. However, that 6% still represents a staggering 108 million tons of plastic waste destined to enter the environment or being openly burned in the year 2050 alone.