linear and branched polymers overview

Linear polymer is a polymer in which the molecules form long chains without branches or cross-linked structures. The molecular chains of a linear polymer may be intertwined, but the forces tending to hold the molecules together are physical rather than chemical and thus can be weakened by energy applied in the form of heat. Such linear polymers are thermoplastics. The simplest polymer is a linear polymer. A linear polymer is simply a chain in which all of the monomers exist in a single line. An example of a linear polymer is Teflon, which is made from tetrafluoroethylene. It is a single strand of units made from two carbon atoms and four fluorine atoms. When formed, these linear polymers can create strands of fibers or form a mesh that can be very strong and hard to break through. These linear polymers are well packed and have high magnitude of intermolecular forces of attraction and therefore have high densities, high tensil (pulling) strength and high melting points. Some common example of linear polymers are high density polyethylene nylon, polyester, PVC, PAN etc.

Linear, Branched, and Cross-linked Polymers:

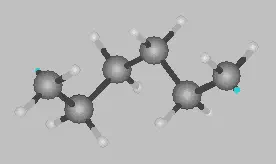

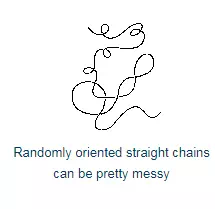

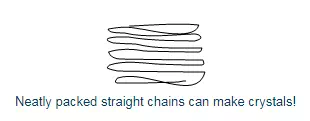

Polyethylene is called a linear or straight-chain polymer because it consists of a long string of carbon-carbon bonds. These terms are misleading because the geometry around each carbon atom is tetrahedral and the chain is neither linear nor straight, as shown in the figure As the polymer chain grows, it folds back on itself in a random fashion to form structures such as the one shown in the figure below on the left. Straight chains can sometimes fold tightly enough to make crystal structures (on the right below) even though the molecules are very long!

Polymers with branches at irregular intervals along the polymer chain are called branched polymers (see figure to the right). These branches make it difficult forthe polymer molecules to pack in a regular array, and therefore make the polymer less crystalline and less dense. The amount and type of branching also affects physical properties such as viscosity and elasticity (see below). Branches often prevent chains from getting close enough together for intermolecular forces to work effectively. they have low tensile strength, low density, boiling point and melting points than linear polymers. Some common examples are low density polythene, glycogen, starch etc. (Amylopectin).

Cross-linked polymers contain short side chains (cross links) that connect different polymer chains into a “network” as shown in the figure to the right. At first, adding cross-links between polymer chains makes the polymer more elastic (they can stretch and return to their original form.) The links can “pull” the chains back together when they are stretched! The vulcanization of rubber, for example, results from the introduction of short chains of sulfur atoms that link the polymer chains in natural rubber. Cross-linking also decreases the viscosity (the resistance to flow) of polymers. In order for polymers to flow, the chains must move past each other and cross-linking prevents this. Elastomers are elastic polymers created by limited cross-linking. As the number of cross-links increases, however, the polymer becomes more rigid and cannot stretch as much; the polymer will become less viscous and less elastic and might even become brittle. e.g., Bakelite, malamine formaldehyde resin etc.