process of Polymerization

It is a chemical process which combines several monomers to form a polymer or a polymeric compound or repetitive bonding of small molecules to produce large molecules. These monomers are small, single molecules such as hydrocarbons and amino acids. The monomer molecules may be alike or different compounds. Some hundreds of monomer molecules are combined to form a polymer that has strong physical properties such as elasticity, high tensile strength or the ability to form fibers. Alkenes formed in straight forward reaction mechanisms form useful compounds such as polyvinyl chloride (PVC) and polyethylene which are used in manufacturing of commercial products such as piping, insulation and packaging.

Polymers such as PVC are called as “homopolymers” as they consist of repeated long chains of the same monomer unit, whereas monomers consisting of more than one molecule are called as “co-polymers”. Molecules consisting of three monomer units are called as “tetramers” or 4 monomer-unit compounds and molecules consisting of more than four monomer units are called as “oligomers”. Polymerization of monomers can be an exothermic process. If polymerization begins when it is not desired, the result could be fire or an explosion. Materials that have this kind of behavior are called as “Hazardous polymerization”. In nature, enzymes carry out polymerization to form proteins, carbohydrates and nucleic acid.

What are the two different types of polymerization?

Condensation polymerization : Each step of this process is accompanied by formation of a molecule of simple compound such as water. Examples of condensation polymerization are polyesters, polyamides, proteins and polysaccharides (cellulose).

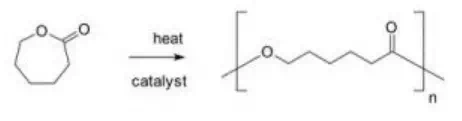

Addition Polymerization : Monomers react to form polymers without forming byproducts.

Step

growth polymerization: Step growth polymers are formed by stepwise reaction

between functional groups of monomers. They are classified as condensation

polymers but not all step growth polymers release condensates. They increase in

molecular weight at lower conversions and moderately higher molecular weight

only at high conversion.

Chain

growth polymerization: It involves the linking together of molecules forming double

or triple chemical bonds. It is involved in the manufacture of polymers such as

polyethylene, polypropylene and polyvinyl chloride (PVC). Chain

growth polymerization leads to living polymerization. Other forms of chain

growth polymerization include cationic addition and anionic addition

which are not used to a large extent but are ideally suited for

living polymerizations.

DNA

polymerization: Nucleic acid synthesis is an anabolic polymerization process. It is the

process of taking nucleotide (building blocks of nucleic acid) monomers and

putting together to form polymers. These three phosphate nucleotide building

blocks of DNA and RNA bring their own energy of polymerization within their

phosphate bonds.

What are the different types of Polymers?

Linear Polymers: They are composed of chainlike molecules and can be viscous liquids or solids with varying degrees of crystalinity, and can dissolve in certain liquids and can melt upon heating.

Cross

linked Polymers: They are network of molecular structure that do not

dissolve in solvents and doesn’t melt upon heating. But these two can be formed

by condensation or addition polymerization.

What are the applications of Polymers?

· Plastics such as polypropylene are used in electrical appliances, automotive applications, ropes, carpets and films in hospitals, homes and schools.

· PVC used in indoor electrical conduit, underground water pipes.

· Teflon used in insulation of wires, motors and generators and anti stick applications in cookware and bearings.

· Polystyrene used in heat and electrical insulation and pipes.

· Polyacrylonitrile used in acrylic fabrics that are stronger than wool.

· Polyvinyl acetate (PVA) is used in adhesives and paints.

· Natural polymers such as rubber and cellulose are used to make everything from tires to cellophane to rayon.

· Deoxyribonucleic acid (DNA) and protein are also natural polymers.