Isoprene Rubber, Polyisoprene (IR)

Polyisoprene rubber has the same basic chemical formula as natural rubber (NR) and thus it is a synthetic version of NR. The study of materials comparable with NR started at the beginning of 20th century, but because of the high price of raw materials and the weak quality of polymers, industrial production was not begun. Significant production was started in the 1970s, when cheaper monomers and catalysts, which produce stereo-specific polymers in solution polymerization became available.

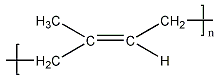

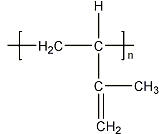

It is possible to create different kinds of isomeric structures using different catalysts and polymerization conditions in the polymerization of isoprene monomers. The structures which are exploitable are 3,4-, cis-1,4- and trans-1,4-polyisoprenes. Cis-1,4 -polyisoprene is a synthetic substitute for natural rubber and trans-1,4-polyisoprene is a hard thermoplastic material (Gutta-percha or Balata).

|

Cis-1,4-addition |

|

|

1,2-addition |

3,4-addition |

The isomeric structures of polyisoprene.

The properties of polyisoprene depend on the amount of its cis-1,4-units. Commercial synthetic isoprene rubbers can be divided in different groups according to the catalyst used:

- The Li-IR group, whose catalyst in polymerization is alkyl lithium. The amount of cis-1,4-units in Li-IR is about 90 % (10% 1,2- type IR). The Ti-IR group. In these polymerizations, the catalysts are different kinds of Ziegler-Natta catalysts. The typical content of cis-1,4-cis-units in Ti-IR is at level 96 - 98 %.

- Lanthanide polyisoprenes have been developed in recent years. They approximate very well to natural rubber. The share of 1,4-cis-units in lanthanide IR can be 99.5 %.

The amount of cis-1,4-units influences crystallization and regularity of the molecule structure. Whit a increase in cis-1,4-content, crystallization is facilitated, the glass transition temperature decreases and strength properties improve. Consequently, strength properties such as modulus, tensile strength and tear resistance are slightly worse in synthetic polyisoprenes than in NR, whose cis-1,4- content is almost 100 %. Also, the building tack of IR is somewhat inferior to that of NR, and the green strength is poorer. Otherwise, the properties of synthetic isoprene rubbers are similar to those of NR. The most significant advantages of synthetic polyisoprenes compared to natural rubber are their purity, good processibility and homogeneity of polymer structure.

Advantages of synthetic IR:

- toughness good abrasion resistance cold resistance competitive price processability and adherence good uncured tack high tensile strength high resilience good hot tear strength

- resistance to many inorganic chemicals

Disadvantages of IR:

- restricted life time at high temperatures and in oxidative conditionspoor oil resistance needs protection against oxygen, ozone and light is not resistant to hydrocarbons

- unsuitable for use with organic liquids

IR is often used with other rubbers. By blending other rubbers with isoprene, tensile and tear strength and flexibility are improved. Applications of IR are similar to natural rubber:

- tyres conveyor lines and transmission straps gaskets, tubes, paddings footwear, sports equipment protective gloves

- sealants and sealing materials

Trans-1,4-polyisoprene (gutta-percha) resembles plastic and is used e.g. in golf balls, deep sea cables, orthopedic applications and adhesives. Gutta-percha can also be obtained from the pruning of special trees which are native to Malaysia.