SPECIALITY POLYMERS: EXPLORING VERSATILITY IN TYPES, APPLICATIONS AND FUTURE PROSPECTS

INTRODUCTION

Speciality Polymers are the class of some HPP, including plastics, polymers, fluids, membranes, smart hydrogels and elastomers that are designed to meet the critical demands of engineers in every day work key industries including, Plastics, Automobiles, Aeronautics, Smart Devices, Healthcare, Pharmacy, Energy Production and Storage.

If we talk about their “special” performance; it includesExceptional heat resistance and chemical inertness; Strength and toughness; Fatigue and wear resistance; Corrosion, abrasion and weathering protection; Water and stain repellence; Electrical inertness; Fire safety; Biocompatibility; Transparency; colors and many more.

This is a short but diversified review of our Post Grad. Students in the area of speciality polymers, their types and applications in engineering, technology and research. The types covered are IPMCs, LCPs, synthetic polymer membranes, smart hydrogels and dendritic polymers.

IPMCs

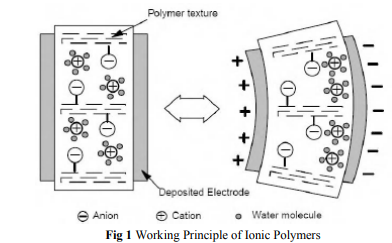

Ionic polymers are, either organic or inorganic, having both covalent and ionic bonds in their molecular structure. This is the basic characteristic feature that distinguishes the ionic polymers from their conventional counterparts. Their working principle is that Water molecules pair with cations. In absence of electric potential, the Water/Cation pairs and the Anions are uniformly distributed as seen in the Left Hand Side of the Fig. 1. When potential is applied, the water/cation pairs and the anions redistribute to balance the charge. This causes the negative side of the polymer to swell more than, resulting in bending.

Due to their ionocity- they play a crucial role in electrochemistry which can be observed by these findings. utilized application of ionic liquid (IL) and their mixture for preparation of advanced polymer blends and composites. ILs and their mixtures used as environmentally friendly solvent, Plasticizer, coupling agent and compatibilizer. proposed characterization of IPMC as a Novel fractional order element. IPMCs are electroactive materials having ionic polymer thin membranes with platinum metallization on their surfaces. They have electrochemical properties between the ionic/solvent current and the potential field. They can be used as compact fractional-order elements (FOEs).

A one-dimensional matlab-model was introduced . He synthesized Ion Conducting Nanocomposite membranes based on polyvinyl alcohol (PVA) blended with hyaluronic acid (HA) and hydroxyapatite (HAP) as nanofiller (PVA-HA-HAP) for fuel cell application and effect of modifier agent of PVA on membrane properties using epichlorohydrin (EPI) as chemical cross linker. The PVA-modifier agent type influenced sharply on most membrane properties. The mechanical properties were improved by increasing the amount of EPI and deteriorated controversially with addition of high incorporated amounts of HAP or OPA or H2SO4 for PVA modification. Electrochemical properties of PVA-HA-HAP composite membranes improved in ionic conductivity with PVA modification and HAP incorporation. used Ionic Liquid-Doped Gel Polymer electrolyte for Flexible Lithium-Ion polymer batteries. He compared them with Sol-gel polymer electrolytes (GPE), earlier used in lithium-ion polymer batteries. IL exhibited superior ionic properties and lower internal resistance compared to GPE. But excess IL damaged internal structure of the batteries and result in unwanted electrochemical reactions, told about application of soft ionic electroactive polymer actuators to fabricate soft robotics. Conventional soft electromechanical actuators, depending upon their design, show linear or circular deformation. Conjugated polymers, Poly (3,4-ethylenedioxythiophene)-poly (styrenesulfonate) (PEDOT:PSS) manipulate ion motion by means of intrinsic angular deformation, which are closer to biomimetic system having potential applications in biorobotics. It was found that dependence of actuator deformation was on structural design which was verified by analytical and finite element method modeling and ion-material interactions that were considerably dominated by the design of the dropcast PEDOT: PSS on Nafion. communicated about Nanothorn electrodes for IPMC artificial muscles. IPMCs have many properties such as soft biomimetic actuators and sensors in various bioengineering and human affinity applications. They are used in artificial muscles and actuators, aquatic propulsors, robotic end-effectors, and active catheters. He used these properties developing, nanostructured electrode surface designed for IPMC by comprising platinum nanothorn assemblies. The highly capacitive properties of nanothorn assemblies increased significantly the charge transport during the actuation process

(Feng and Huang, 2016), studied mechanical and electrical behavior of a tuning fork-shaped IPMC actuator with a Continuous Water Supply Mechanism. With an integrated soft strain gauge and water supply mechanism (WSM), the surface strain of the actuator shows sensed properties in situ and providing a continuous water supply maintains the water content inside the IPMC for long-term operation in air. The actuator is fabricated using a micromachining technique and plated with a nickel electrode and compared with an actuator without a WSM. About1.5 mm displacement was found for a 6 mm-long prong with 7-V dc (measured by electrochemical model) actuation applied for 30 s. This faradaic current has crucial activity during operation, particularly after 10 s. The calculated strains have bending and axial strain generation during the open-and-close motion of the actuator prongs. Most of the water loss during device operation was due to evaporation rather than hydrolysis. The constructed WSM effectively maintained the water content inside the IPMC for long term continuous operation.

(Chatterjee, 2015), worked on IPMC based devices for nakedeye sensing of Thiocyanate Ion (SCN-2 ), which was detected by using ion exchanged IPMC useful for direct determination of thiocyanate at micro-molar level in water samples. But the response time of the sensor in whole concentration ranges was very short (<10 s) and it is independent of the pH range of 2- 10. (Liu et al, 2012), directly observed ion distributions near electrodes in ionic polymer actuators containing ionic liquids (ILs). The recent boom of energy storage and conversion devices introduced by exploiting ILs to enhance the performance also requires an in-depth understanding of this new class of electrolytes in device operation conditions. The present excess ion depth profiles of ILs in ionomer membrane actuators (Aquivion/1-butyl-2, 3-dimethylimidazolium chloride (BMMI-Cl), 27 mm thick), was characterized directly by Timeof-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) at liquid nitrogen temperature. The large difference in the total volume occupied by the excess ions between the two electrodes gives large bending actuation of the actuator. Those Organic liquid electrolytes which have leakage, flammability and chemical stability issues, solid electrolytes are used to manufacture lithium-ion batteries. Composite polymer electrolyte with well-aligned inorganic Li+-conductive nanowires have ionic conductivity which is one order of magnitude higher than previous polymer electrolytes with randomly aligned nanowires. Accordingly (Liu et al., 2017), the large conductivity enhancement is ascribed to a fast ionconducting pathway without crossing junctions on the surfaces of the aligned nanowires and long-term structural stability of the polymer electrolyte is improved by using nanowires. (Esmail et al., 2017), proposed a NOVEL humidity sensor based on IPMC. It was fabricated by weak adhesive force between electrodes and the polymer and peeling off phenomenon. Adhesion layers are formed between polymer and Au electrodes. A different fabricated IPMC electrode acted as a capacitor which measured relative humidity conditions and> <10 s ) and it is independent of the pH range of 2- 10.

(Liu et al, 2012), directly observed ion distributions near electrodes in ionic polymer actuators containing ionic liquids (ILs). The recent boom of energy storage and conversion devices introduced by exploiting ILs to enhance the performance also requires an in-depth understanding of this new class of electrolytes in device operation conditions. The present excess ion depth profiles of ILs in ionomer membrane actuators (Aquivion/1-butyl-2, 3-dimethylimidazolium chloride (BMMI-Cl), 27 mm thick), was characterized directly by Timeof-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) at liquid nitrogen temperature. The large difference in the total volume occupied by the excess ions between the two electrodes gives large bending actuation of the actuator.

Those Organic liquid electrolytes which have leakage, flammability and chemical stability issues, solid electrolytes are used to manufacture lithium-ion batteries. Composite polymer electrolyte with well-aligned inorganic Li+-conductive nanowires have ionic conductivity which is one order of magnitude higher than previous polymer electrolytes with randomly aligned nanowires. Accordingly (Liu et al., 2017), the large conductivity enhancement is ascribed to a fast ionconducting pathway without crossing junctions on the surfaces of the aligned nanowires and long-term structural stability of the polymer electrolyte is improved by using nanowires. (Esmail et al., 2017), proposed a NOVEL humidity sensor based on IPMC. It was fabricated by weak adhesive force between electrodes and the polymer and peeling off phenomenon. Adhesion layers are formed between polymer and Au electrodes. A different fabricated IPMC electrode acted as a capacitor which measured relative humidity conditions and the relative humidity variations at different deflections and relative humidity conditions.

Dynamic pressure based IPMC sensors were designed (Gurdarzi et al., 2017), on the basis of streaming potential hypothesis and calibrated them in a standard tube. With the help of sensing mechanism and applied direct assembly process (DAP) to fabricate some pressure sensor samples, equivalent resistance and capacitance of the samples using impedance analyzer were calculated. These dynamic pressure sensors represent an appropriate linearity, sensitivity and reliability and DAP is a consistent fabrication process for making these types sensors.

An ample amount of work was reported by various scientists on applicability of IPMCs very recently.

(Leones et al., 2017), discussed about phenomenon of uncover novel polymer electrolytes. Solvent casting method is applied to synthesis solid polymer electrolytes (SPEs) which work on the principle of chitosan and fourteen ionic liquids (ILs) having 1-ethyl-3-methylimidazolium cation ([C Many properties such as thermal, morphological, and electrochemical of the SPEs are affected by influence of the anion . These are explained with help of thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), X diffraction (XRD), scanning electron microscopy (SEM), atomic force microscopy (AFM), complex impedance spectroscopy (ionic conductivity) and cyclic voltammetry. The SPEs shows amorphous morphology, high thermal stability than pure chitosan matrix.

(Obeidat et al., 2017), fabricated solid-state supercapacitors with ionic liquid gel polymer electrolyte and polypyrrole electrodes for electrical energy storage. formed by mixing of ionic liquid 1-butyl-3methylimidazolium tetrafluoroborate (BMIBF4) with poly (vinylidene fluoridehexafluoropropylene) P(VdF-HFP). The polypyrrole electrode is formed by ultra-short pulsed current electro polymerization over flexible graphite sheets, and synthesized with the help of LiClO4 and H2SO4 electrolytes. These electrodes are conditioned though cyclic voltammetry (CV). The electrochemical properties of PPy solid capacitor is calculated by CV, CD, and EIS with highest area capacitance density about 31.84 mF cm−2 which is equivalent to a specific capacitance of 19.9 F g−1.

A very interesting work on pollutants was proposed ( 2017), discussed about Fabrication of polymeric ionic liquid modified magnetic adsorbent for extraction of apolar and pollutants in complicated samples. Simple free radical copolymerization of 1-vinylbenzyl-3-methylimidazolium hexafluorophosphate, divinylbenzene and silica magnetite are used for preparation of PIL characterized. Parameters such as adsorption, desorption, pH for magnetic solid phase extraction (MSPE) were optimized. Convenient and sensitive analytical methods for parabens and aromatic amines in real samples are introduced by the mixing of PIL-MA-MSPE and HPLC-DAD at the same time. A result abundant active groups in the PILinteractions including π-π, hydrophobic, hydrogen dipole-dipole were present in preparation.