General Definition - II

Base Metal.

The metal to be welded, brazed, soldered, or cut. It is also referred to as parent metal.

Bell-Welded Pipe.

Furnace-welded pipe produced in individual lengths from cutlength skelp, having its longitudinal butt joint forge-welded by the mechanical pressure developed in drawing the furnace-heating skelp through a cone-shaped die (commonly known as a welding bell), which serves as a combined forming and welding die.

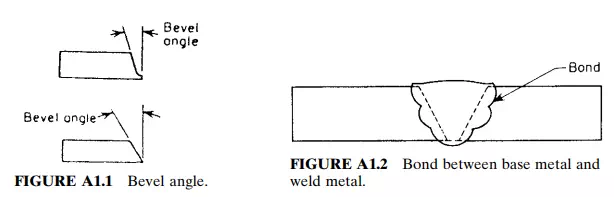

Bevel.

A type of edge or end preparation. Bevel Angle. The angle formed between the prepared edge of a member and a plane perpendicular to the surface of the member. See Fig. A1.1.

Blank Flange.

A flange that is not drilled but is otherwise complete.

Blind Flange.

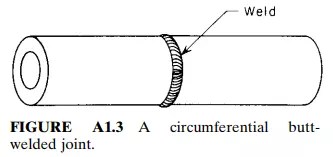

A flange used to close the end of a pipe. It produces a blind end which is also known as a dead end. Bond. The junction of the weld metal and the base metal, or the junction of the base metal parts when weld metal is not present. See Fig. A1.2.

Branch Connection.

The attachment of a branch pipe to the run of a main pipe with or without the use of fittings.

Braze Welding.

A method of welding whereby a groove, fillet, plug, or slot weld is made using a nonferrous filler metal having a melting point below that of the base metals, but above 800F. The filler metal is not distributed in the joint by capillary action.5 (Bronze welding, the term formerly used, is a misnomer.)

Brazing.

A metal joining process in which coalescence is produced by use of a nonferrous filler metal having a melting point above 800F but lower than that of the base metals joined. The filler metal is distributed between the closely fitted surfaces of the joint by capillary action.5 Butt Joint. A joint between two members lying approximately in the same plane.

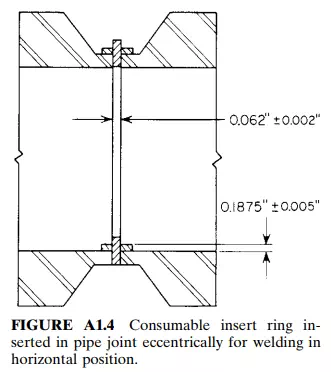

Butt Weld.

Weld along a seam that is butted edge to edge. See Fig. A1.3.

Bypass.

A small passage around a large valve for warming up a line. An emergency connection around a reducing valve, trap, etc., to use in case it is welded joint. out of commission.

Carbon Steel.

A steel which owes its distinctive properties chiefly to the carbon (as distinguished from the other elements) which it contains. Steel is considered to be carbon steel when no minimum content is specified or required for aluminum, boron, chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium, or zirconium or for any other element added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese, 1.65 percent; silicon, 0.60 percent; copper, 0.60 percent.

Cast Iron.

A generic term for the family of high carbon-silicon-iron casting alloys including gray, white, malleable, and ductile iron.

Centrifugally Cast Pipe.

Pipe formed from the solidification of molten metal in a rotating mold. Both metal and sand molds are used. After casting, if required the pipe is machined, to sound metal, on the internal and external diameters to the surface roughness and dimensional requirements of the applicable material specification.

Certificate of Compliance.

A written statement that the materials, equipment, or services are in accordance with the specified requirements. It may have to be supported by documented evidence.

Certified Material Test Report (CMTR).

A document attesting that the material is in accordance with specified requirements, including the actual results of all required chemical analyses, tests, and examinations.

Chamfering.

The preparation of a contour, other than for a square groove weld, on the edge of a member for welding.

Cold Bending.

The bending of pipe to a predetermined radius at any temperature below some specified phase change or transformation temperature but especially at or near room temperature. Frequently, pipe is bent to a radius of 5 times the nominal pipe diameter.

Cold Working.

Deformation of a metal plastically. Although ordinarily done at room temperature, cold working may be done at the temperature and rate at which strain hardening occurs. Bending of steel piping at 1300F (704C) would be considered a cold-working operation.

Companion Flange.

A pipe flange suited to connect with another flange or with a flanged valve or fitting. A loose flange which is attached to a pipe by threading, van stoning, welding, or similar method as distinguished from a flange which is cast integrally with a fitting or pipe.

Consumable Insert.

Preplaced filler metal which is completely fused into the root of the joint and becomes part of the weld.

Continuous-Welded Pipe.

Furnace welded pipe produced in continuous lengths from coiled skelp and subsequently cut into individual lengths, having its longitudinal butt joint forgewelded by the mechanical pressure developed in rolling the hot-formed skelp through a set of round pass welding rolls.

Control Piping.

All piping, valves, and fittings used to interconnect air, gas, or hydraulically operated control apparatus or instrument transmitters and receivers.

Controlled Cooling.

A process of cooling from an elevated temperature in a predetermined manner to avoid hardening, cracking, or internal damage or to produce a desired metallurgical microstructure. This cooling usually follows the final hot-forming or postheating operation.

Corner Joint.

A joint between two members located approximately at right angles to each other in the form of an L.

Coupling.

A threaded sleeve used to connect two pipes. Commercial couplings have internal threads to fit external threads on pipe.

Covered Electrode.

A filler metal electrode, used in arc welding, consisting of a metal core wire with a relatively thick covering which provides protection for the molten metal from the atmosphere, improves the properties of the weld metal, and stabilizes the arc. Covered electrodes are extensively used in shop fabrication and field erection of piping of carbon, alloy, and stainless steels.

Crack.

A fracture-type imperfection characterized by a sharp tip and high ratio of length and depth to opening displacement.

Creep or Plastic Flow of Metals.

At sufficiently high temperatures, all metals flow under stress. The higher the temperature and stress, the greater the tendency to plastic flow for any given metal.

Cutting Torch.

A device used in oxygen, air, or powder cutting for controlling and directing the gases used for preheating and the oxygen or powder used for cutting the metal.

Defect.

A flaw or an imperfection of such size, shape, orientation, location, or properties as to be rejectable per the applicable minimum acceptance standards.

Density.

The density of a substance is the mass of the substance per unit volume. It may be expressed in a variety of units. Deposited Metal. Filler metal that has been added during a welding operation.

Depth of Fusion.

The distance that fusion extends into the base metal from the surface melted during welding.

Designer.

Responsible for ensuring that the engineering design of piping complies with the requirements of the applicable code and standard and any additional requirements established by the owner.

Dew Point.

The temperature at which the vapor condenses when it is cooled at constant pressure.

Dilatant Liquid.

If the viscosity of a liquid increases as agitation is increased at constant temperature, the liquid is termed dilatant. Examples are clay slurries and candy compounds.

Discontinuity.

A lack of continuity or cohesion; an interruption in the normal physical structure of material or a product.

Double Submerged Arc-Welded Pipe.

Pipe having a longitudinal butt joint produced by at least two passes, one of which is on the inside of the pipe. Coalescence is produced by heating with an electric arc or arcs between the bare metal electrode or electrodes and the work. The welding is shielded by a blanket of granular, fusible material on the work. Pressure is not used, and filler metal for the inside and outside welds is obtained from the electrode or electrodes.

Ductile Iron.

A cast ferrous material in which the free graphite is in a spheroidal form rather than a fluke form. The desirable properties of ductile iron are achieved by means of chemistry and a ferritizing heat treatment of the castings.