Pressure Binding

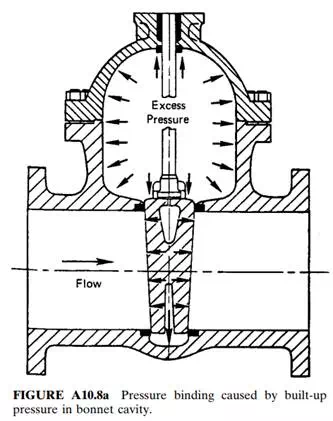

Sometimes in high-temperature applications, the flow medium, such as water or steam, is trapped in the valve bonnet area when the valve is closed for system shutdown. The valves that do not permit this trapped liquid or the condensate to reenter the piping either upstream or downstream may experience excessive pressures in the bonnet cavity when the system returns to operating temperature. This built-up pressure in the bonnet cavity can prevent the valve from opening and may cause damage to valve parts. See Fig. A10.8a.

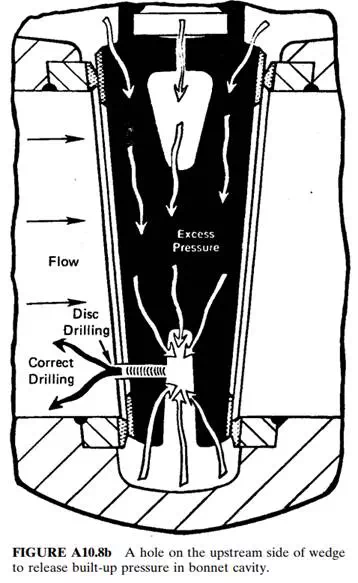

Pressure binding may not occur if the leakage past the upstream seat is adequate to prevent overpressurization of the valve bonnet cavity. The following options offer solutions to this problem:

● Drill a small hole on the upstream side of the disc. See Fig. A10.8b.

● Install a small manual stop valve between the valve bonnet-neck and the upstream end of the valve. This valve shall be opened during startup.

● Install a small relief valve in the bonnet.

● Edward valves offer a new valve called ACEVE to solve this problem

Typical Gate Valve Applications

Socket or butt-welding end-gate valves in air, fuel gas, feedwater, steam, lube oil, and other systems are typical applications. Threaded-end gate valves may be used in air, gaseous, or liquid systems. Concern for leakage from threaded connection can be addressed by seal welding the threaded connection or by using thread sealants, as appropriate. In low-pressure and low-temperature systems such as fire protection systemsí water piping or water distribution pipelines, flanged gate valves are commonly used.