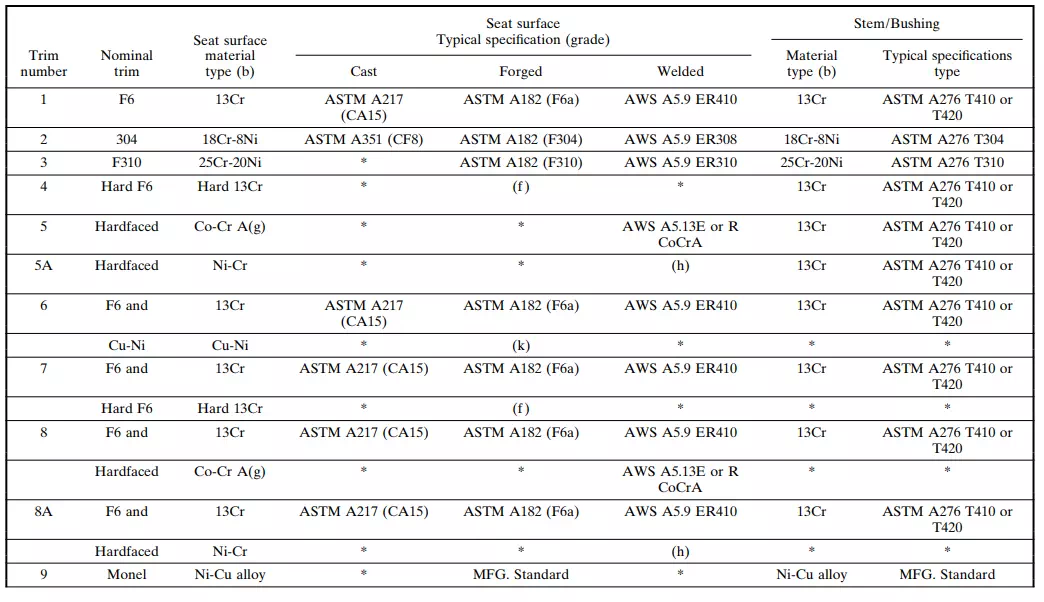

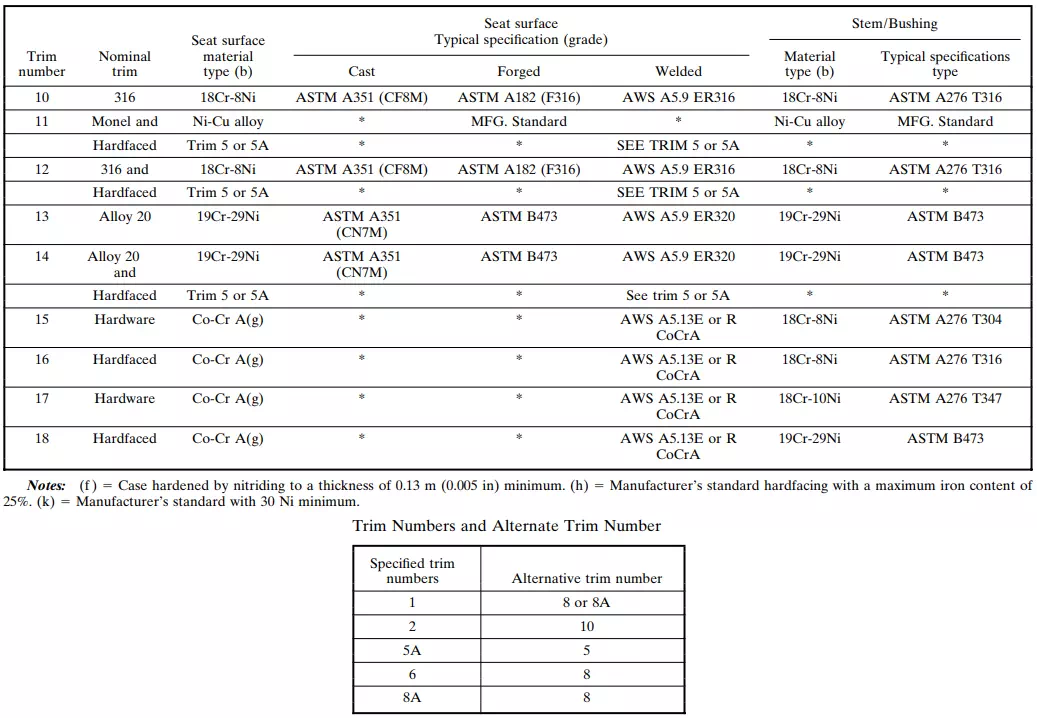

API Trim Materials

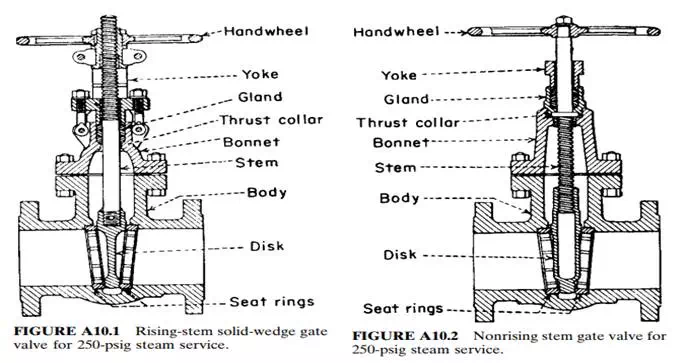

Rising Stem with Inside Screw. The threaded part of the stem is inside the valve body, and the stem packing is along the smooth part that is exposed to the atmosphere outside. In this case the stem threads are in contact with the flow medium. When rotated, the stem and the handwheel rise together to open the valve. This design is commonly used in the smaller-sized low-to-moderate pressure gate, globe, and angle valves.

Non-rising Stem with Inside Screw. The threaded part of the stem is inside the valve and does not rise. The valve disc travels along the stem like a nut when the stem is rotated. Stem threads are exposed to the flow medium and, as such, are subjected to its impact. Therefore, this design is used where space is limited to allow linear stem movement, and the flow medium does not cause erosion, corrosion, or wear and tear of stem material.

Sliding Stem. This stem does not rotate or turn. It slides in and out of the valve to close or open the valve. This design is used in hand-lever–operated quickopening valves. It is also used in control valves that are operated by hydraulic or pneumatic cylinders.

Rotary Stem. This is a commonly used design in ball, plug, and butterfly valves. A quarter-turn motion of the stem opens or closes the valve.