Classification of Valves

The following are some of the commonly used valve classifications:

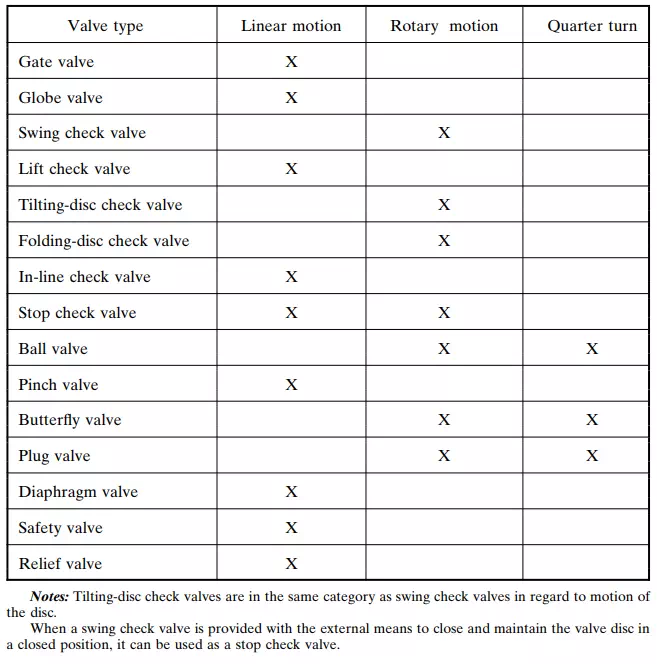

Classification Based on Mechanical Motion

Based on the mechanical or cyclical motion of the valve closure member, valves are classified as follows:

Linear Motion Valves.

The valves in which the closure member, as in gate, globe, diaphragm, pinch, and lift check valves, moves in a straight line to allow, stop, or throttle the flow.

Rotary Motion Valves.

When the valve-closure member travels along an angular or circular path, as in butterfly, ball, plug, eccentric- and swing check valves, the valves are called rotary motion valves.

Quarter Turn Valves.

Some rotary motion valves require approximately a quarter turn, 0 through 900, motion of the stem to go to fully open from a fully closed position or vice versa.

Classification Based on Valve Size Valve Size.

Valve size is denoted by the nominal pipe size (NPS), which is equal to the size of valve-connecting ends or the flange-end size. In the metric system, valve size is designated by the nominal diameter (DN) of connecting pipe or the connecting flange ends. When a valve is installed with reducers on each end, the size of the valve will be equal to the size of the reducer-connecting ends attached to the valve. The valve size is not necessarily equal to the inside diameter of the valve.

It is a normal industry practice to categorize valves, based upon size, in two classification: small and large.

Small Valves. NPS 2 (DN 50) and smaller valves are called small valves. At times, NPS 2¹⁄₂ (DN 65) and smaller valves are referred to as small valves. As such, the size classification can vary and, therefore, it should not be considered a uniform industry practice.

Large Valves. NPS 2¹⁄₂ (DN 65) and larger valves are classified as large valves. As indicated earlier, NPS 2¹⁄₂ (DN 65) valves may be designated as small valves, depending on the criteria used in classifying small valves.

Classification Based on Pressure-Temperature Rating Class Ratings.

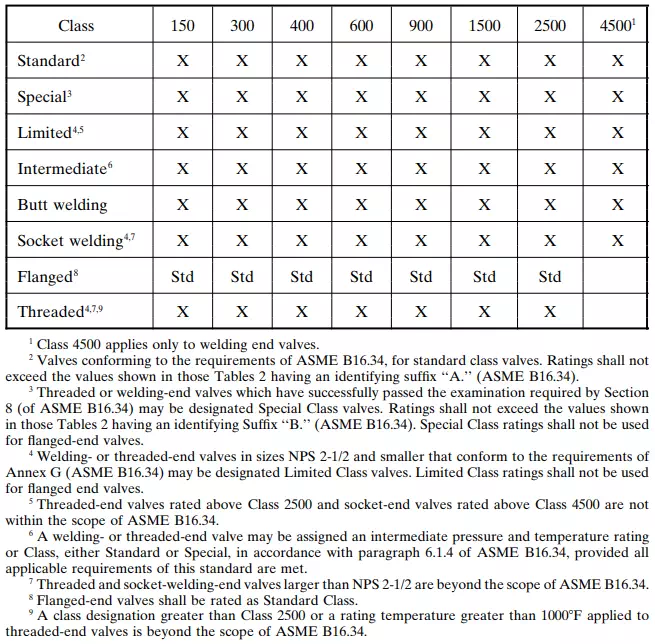

Pressure-temperature ratings of valves are designated by class numbers. Based on the material(s) of construction, the pressure-temperature ratings for each class are tabulated to provide the maximum allowable working pressures, expressed as gauge pressures, at the temperature shown. The temperature shown for a corresponding pressure rating is the temperature of the pressure-containing shell of the component. Items such as a piping system or a portion thereof, a pump, tank, heat exchanger, pressure vessel, valves, et cetera are considered components. ASME B16.34, Valves—Flanged, Threaded, and Welding End is one of the most widely used valve standards. It defines three types of classes: standard, special, and limited. ASME B16.34 covers Class 150, 300, 400, 600, 900, 1500, 2500, and 4500 valves. It also allows valves to be classified as intermediate whose pressure temperature ratings may fall within those listed for the standard and special class valves. See Table A10.2 for valve classifications and their limitations covered by ASME B16.34.

Tables A10.3 and A10.4 provide a listing of valve classes covered by various commonly used valve standards published by the Manufacturers Standardization Society (MSS) and the American Petroleum Institute (API). Table A10.5 provides a brief summary of valves covered by AWWA standards.