Equipment and Piping Layout

Arrangement of equipment’s and piping is a primary activity of a piping engineering department. Preliminary equipment layout is done before piping study. Final equipment locations are decided based on all piping layout requirements are considered.

Equipment layout and piping layout is done as per general industry practice as well as piping design basis, process flow, gravity requirements, structure philosophy. Check out following articles targeting various aspects of equipment and piping layout. Your suggestions and comments are highly welcomed.

Equipment Layout : General Considerations

Process flow sequence and operating procedures should be thoroughly understood so that equipment arrangement in the plot plan is functional. Equipment should be arranged in logistic process sequence for optimum piping runs and operational and maintenance ease. Spacing between equipment shall be adequate for undertaking maintenance jobs.

The unit pipe rack should be kept in the centre, thereby splitting the unit into two or more areas of equipment. Pumps may be arranged in two rows close to and on either side of the pipe rack. Heat Exchangers and vessels should be grouped together forming outer rows on both sides of the rack.

Horizontal Clearances in a Process Plant

|

Sr. |

Description |

Distance (mm) |

|

1 |

From centerline railroad track to any obstruction |

3000 |

|

2 |

Width of primary and secondary road excluding 1500 mm shoulders |

6000 |

|

3 |

Clearance from edge of road shoulder to nearest structure, equipment or piping |

1500 |

|

4 |

Horizontal clearance for equipment maintenance by manual equipment, passage way at grade or access isle |

1200 |

|

5 |

Minimum clear platform width in front of equipment manways |

900 |

|

6 |

Minimum clearance around any obstruction on a platform |

600 |

|

7 |

At driver end of pumps, where truck access is required |

3000 |

|

8 |

At driver end of pumps, where truck access is not required |

1500 |

|

9 |

For compressors: removal length of piston and end assembly plus this much mm from inside of building wall or adjacent equipment |

1500 |

|

10 |

At shell cover end of exchangers at grade, for accessway |

1200 |

|

11 |

Maintenance platforms at ends of elevated exchangers |

900 |

|

12 |

Between extremities, including piping of adjacent pumps |

900 |

Access Requirement Criteria

|

Sr. |

Component |

Min Access Required |

|

1 |

Small Thermal Relief Valves in Piperack |

Portable Ladder |

|

2 |

Orifice Run in Pipe Rack |

Portable Ladder |

|

3 |

Relief Valves above 5 Meters from Grade |

Permanent Platform |

|

4 |

Frequent Operation Components |

Permanent Platform |

|

5 |

Equipment Manways and Nozzle upto 4500 mm from Grade |

Portable Platform |

|

6 |

Equipment Upto 3000 mm above Grade |

Portable Platform |

Headrooms in Process Unit

|

Sr. |

Description |

Distance (mm) |

|

1 |

Over Primary Plant Roads |

5500 |

|

2 |

Over Accessways in Process Unit |

4600 |

|

3 |

Over railroads, Top of rail to bottom of overhead obstruction |

7000 |

|

4 |

Over Primary Access Roads |

6500 |

|

5 |

Under Pipe Racks for Equipment Access |

3000 |

|

6 |

Over Pumps and Turbines from Grade |

2400 |

|

7 |

Over walkways, passageways and platforms to nearest obstruction |

2150 |

Platform, Ladders and Stairways

Platforms, ladders and stairways shall be in the minimum consistent with access and safety requirements. Access to platforms shall be by permanent side step ladder.

The need for stairways shall be determined based on platform elevation, number of points requiring attention, observation and adjustments and the frequency of same. When there is more than 23000 mm of travel from the primary access on a platform, a secondary means of escape shall be provided. Safety cages not required for ladders serving platform 2500 mm or less above the high point of finished surface.

Safety cage not required for ladders serving platforms 2500 mm or less above originating platform provided the space between the ladder and the edge of the platform is a minimum of 1200 mm. Safety cages are not required for short ladders.

Maximum uninterrupted ladder length distance between vertical platforms shall not exceed 9000 mm. Maximum rise on a staircase shall not exceed 20 steps. The preferred distance of a platform below the centerline of a manway shall be 750 mm, max 1000mm and min 600 mm.

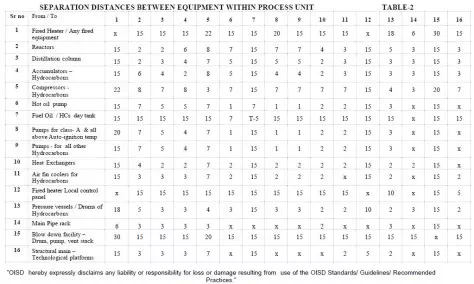

Spacing Between Equipments

Equipment should be spaced to permit use of mobile equipment and power tools or servicing and maintaining equipment during turn around periods.

OISD 118 Table-2 Should be followed for Indian Projects.

Piping Layout : General Considerations

Piping Layout must be carried out with Process requirements, economy, orderliness, stress and supporting requirements in mind. Following points shall be adhered to for optimum pipe routing.

Orderliness

Piping shall be arranged in an orderly manner and routed as directly as practical, preferably in established banks or pipeways.

Thermal Expansion and Stresses

Arrangement shall provide for natural loops and offsets to compensate for thermal expansion and contraction of lines. Reactions or moments causing excessive stresses in piping or equipment shall be avoided by proper design.

Dynamic Loading

Where dynamic loading, limited pressure drop, or other severe service conditions apply, particular care shall be used in routing the piping. Dynamic loading may be expected when pulsating flow such as at reciprocating compressors and high velocity flow, flashing fluid, fluctuating temperature or pressure, or mechanical vibration (including wind) conditions exist. Piping subject to possible dynamic loading shall be carefully designed and checked to ensure that its size, configuration, mechanical strength, supports and restraints will prevent excessive stresses, vibration or noise.

Pressure Drop Restrictions

Limited pressure drop conditions may be expected in large vapour lines, heater transfer lines, reboiler circuits, pump suctions and gravity flow lines. Such piping shall be routed as directly as practicaL.

Costly Materials

Other severe services include erosive, corrosive and high or low temperature or pressure conditions. Many such services require alloy or other special materials. Piping in these services shall be routed to minimize the effects of service severity and make most practical use of required special materials.

Pipe Racks

Pipeways shall be sized for present needs plus 15%. As far as practical, piping shall run at different elevations in north-south and east-west banks, and shall change elevation when changing direction. Combined changes of direction and elevation in pipeways ordinarily shall be made with 90° elbows. Where necessary, a 90° and a 45° elbow can be used. Inside buildings, piping may run in vertical banks and flat turns may be used.

Chemical Injection Piping

All injection points into hazardous lines (i.e. high pressure, sour or dangerous) shall have a block valve and check valve located as close as practical to the injection point.

Liquid Sulfur Piping

All flanged connections shall have two sockets on threadolets, installed in the jackets as close to the flanges as possible on flange centerline. All piping bends shall be made with welded crosses, installed complete with flanges and plugs for cleaning. All runs of pipe shall contain a sufficient number of breakout flanges and all laterals shall be connected to mains through pipe crosses with flanges on onnecting ends of laterals with flanges and blinds on opposite sides. Suffcient connections for steaming, blowing, draining and rodding shall be provided on all sulphur lines. All liquid sulphur lines shall be sloped to the sulphur pit and shall be drainable.

Sample Connections Piping

Sample stations shall be provided with 3/4″ main valve on the feed and return. Where liquid samples are taken in a bottle, the sample outlet shall be located above a drain funnel to permit free running of the liquid before sampling. Liquid sample connections shall be taken off the side of the pipe.