Piping Material Specification for Steel Pipes

Specifying Pipes in PMS involves indication of following information.

Size Range

Size range specified will be as per Concerned Spec Purpose and Type of Pipe Construction such as Seamless or Welded.

Construction

Pipe can be Seamless for upto 24″. Higher sizes can be welded e.g. ERW or EFW depending of Material of Construction.

Radiography

Radiography will be specified as per applicable code for the concerned piping system. e.g. ASME B36.3.

e.g. : 100# RX (Only for Welded Pipes)

Material of Construction

Choice of piping material depends on temperature and fluid properties.

E.g. Material : ASTM A106 Gr. B Seamless, A672 Gr. B65 Cl.42 for EFW etc.

Pipe End Type

Pipe end type depends on Pipe Size and Fittings End Type. Small bore piping is Socketwelding or Threaded. Big Bore piping Buttwelded.

Ends : Plane End for small bore, Bevelled End for Big Bore

Dimensional Standard

Dim Standard : ASME B36.10 for CS Pipe, ASME B36.19 for SS Pipe

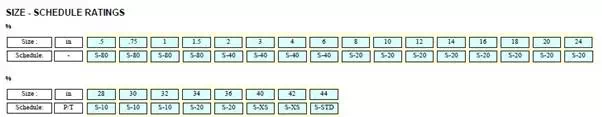

Pipe Thickness

Pipe thickness is calculated as per applicable piping code such as ASME B36.3. Based on calculated size, standard pipe thickness is chosen from pipe dimensional standard specified as above. Thicknesses for all applicable pipe sizes is specified in separate chart in Piping Material Specification.

Example Chart :