Piping Materials : Steel Pipes

Pipes are the main component transporting fluid from one place to another. They must be carefully chosen for long term safe opration of the plant. Their selection mainly involves choice of :

1. Material of Construction.

2. Nominal Pipe Size.

3. Wall Thickness.

4. Pipe End Type.

Straight pipe is supplied in ‘random’ lengths (17 to 25 ft), and sometimes ‘double random’ lengths (38 to 48 ft), if preferred. Wall thickness of pipes is defined by ‘schedule nurnber, ‘API designation’, or ‘weight’. Non-standard pipe is specified by nominal size with wall thickness stated.

Steel Pipes : Dimensional Standards

Most widely used dimensional standards for Steel Pipes are ASME B36.10M and ASME B36.19M.

ASME B36.10M : Dimensional Standard for Carbon Steel Pipes.

1. Available Size range of pipes is from 1/8″ to 80″ NPD.

2. The manufacture of pipe NPS 1/8″ to NPS 12″ inclusive is based on standardized outside diameter (OD).

3. The manufacture of pipe NPS 14 and larger is based on OD corresponding to nominal size.

4. This standard provides formula for calculating weight of pipe in lb/foot and kg/m.

5. The threads of threaded pipe should confirm to ASME B1.20.1, Pipe threads, General Purpose (Inch).

6. Schedule 5 and 10 wall thickness do not permit threading as per ASME B1.20.1

7. Standard and Sch.40 are identical upto 10″ inclusive. All larger sizes of Standard have 9.53mm wall thickness.

8. Extra Strong and Schedule 820 are identical upto 8″. All larger sizes of XS have 12.7 mm wall thickness.

9. Pipes of wall thicknesses other than those of STD, XS, XXS and Sch numbers were adopted from API Specification 5L. No schedule numbers are allotted to them.

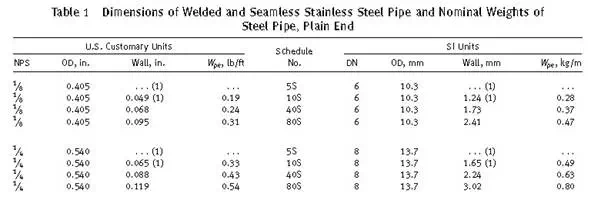

Table 1 of this standard provides dimensions of pipes.

ASME B36.19M : Dimensional Standard for Stainless Steel Pipes.

1. Available size range of pipes is from 1/8″ to 30″ NPD.

2. Pipes 12″ and smaller have outside dia numerically larger than their corresponding sizes.

3. The wall thickness for 14″ to 22″, of sch 10S, 12″ of Sch 40S and 10″,12″ of Sch 80S are not same as those of ASME B36.10M.

4. Suffix S is added to differentiate thicknesses from B36.10M thicknesses.

5. The manufacture of pipe NPS 1/8″ to NPS 12″ inclusive is based on standardized outside diameter (OD).

6. The manufacture of pipe NPS 14 and larger is based on OD corresponding to nominal size.

7. This standard provides formula for calculating weight of pipe in lb/foot and kg/m.

8. The threads of threaded pipe should confirm to ASME B1.20.1, Pipe threads, General Purpose (Inch).

9. Schedule 5 and 10 wall thickness do not permit threading as per ASME B1.20.1

Table 1 of this standard provides dimensions of pipes.

Wall Thickness Calculations

The nominal weights of steel pipe are calculated values and are tabulated in Table 1 of these standards. The nominal plain end weight, in pounds per foot, is calculated using the following formula:

Pounds per foot

W = 10.69(D-t)t

Kg per Meter

W = 0.0246615(D-t)t

Where :

· D : Pipe outside diameter.

· t : Specified wall thickness.

· W : The nominal plain end mass, in pounds per foot or kilograms per meter.