Spiral Heat Exchangers Equipment and Piping Layout

Spiral heat exchangers are mostly used in chemical plants. They are special layout needs w.r.t. their construction such as cover plate swing area.

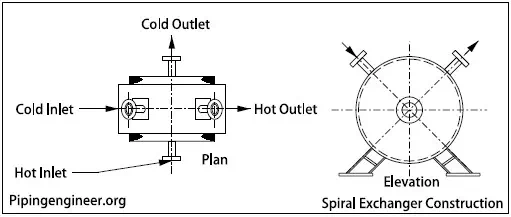

Spiral Heat Exchanger Construction

1. They are of circular construction as shown in figure below.

2. They consist of two long strips of plate, wrapped to form a pair of concentric spiral passages.

3. Alternate edges of the passage are closed, so that liquid flow through continuous channels.

4. Removable covers are fitted to each side of the spiral assembly for access to spiral plates.

5. The inlet and outlet nozzles are integral to the plate housing and covers.

6. For vertical installations, lugs are used for supporting this equipment.

7. For horizontal installations, legs are used.

8. These exchangers are compact and require less installation and servicing space than conventional exchangers of equivalent surface area.

Spiral Exchangers Construction

Spiral Heat Exchanger Location and Support

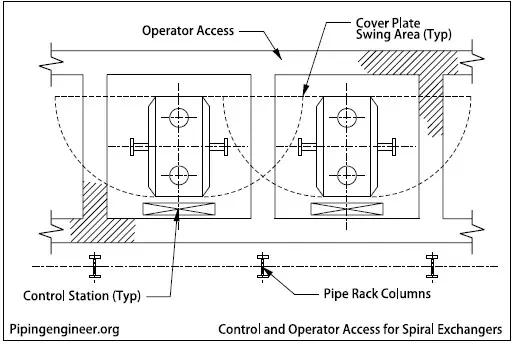

Spiral heat exchangers can operate in series or parallel but because of their configuration and maintenance requirements, it is preferable to position them as single items.

It is necessary to provide space for control and operator access, with enough room to swing the cover plates open.

Control and Operator Access for Spiral Exchangers

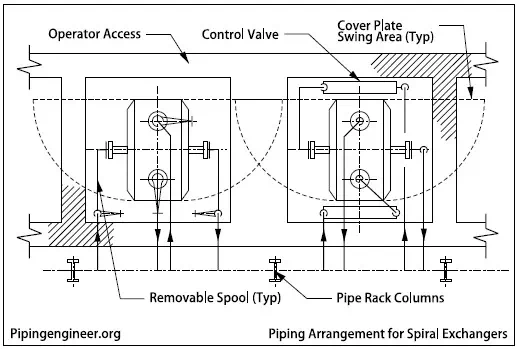

Spiral Exchanger Piping Arrangement

1. Position piping to allow the opening of cover plates.

2. Locate controls on the ends of unit, clear of cover swing area.

3. Furnish break flanges in piping attached to the cover plate nozzles.

Piping Arrangement for Spiral Exchangers

Spiral Heat Exchanger Internal

Spiral Heat Exchanger Piping Layout