Introduction to Heat Exchangers

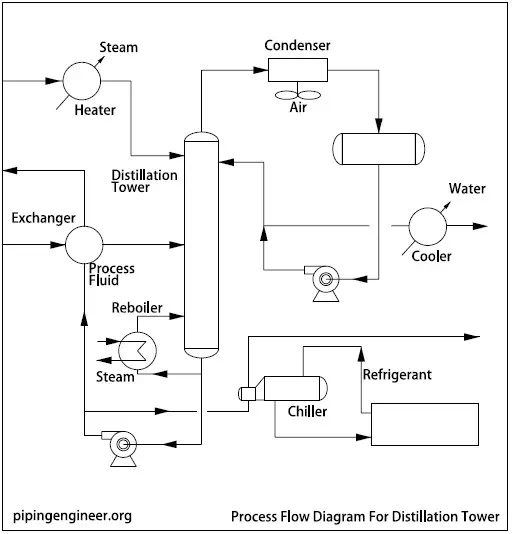

Heat exchangers are similar to pumps and vessels in that they are widely used in most process plants. The control of heat within any facility is an important part of plant operation, whether by direct application (e.g. in a furnace) or by heat interchange (e.g. in a shell and tube exchanger.)

The principal application of a heat exchanger is to maintain a heat balance through the addition or removal of heat exchange with outside sources or between streams of two different operating temperatures.

The most common applications of heat exchangers are :

1. Cooler – Cools process streams by transferring heat to cooling tower, atmosphere and other media.

2. Exchanger – Exchanges heat from hot to cold process stream.

3. Reboiler – Boils process liquids in tower bottoms using steam, hot oil or a hot process stream as the heating medium.

4. Heater – Heats a process stream by condensing steam.

5. Condenser – Condenses vapors by transferring heat to cooling water, atmospheric air or other media.

6. Chiller – Cools a process stream to very low temperatures by evaporating a refrigerant.

Types of Heat Exchangers :

Most common types of heat exchangers are as follows :

Shell and Tube Heat Exchanger

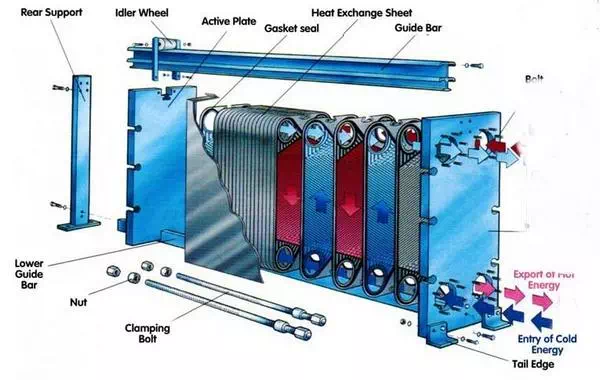

Plate Heat Exchanger

Plate Heat Exchanger Construction

Spiral Heat Exchanger

Spiral Heat Exchanger Internal

Double Pipe Heat Exchanger

Double Pipe Heat Exchanger Piping

Air Cooler Exchanger