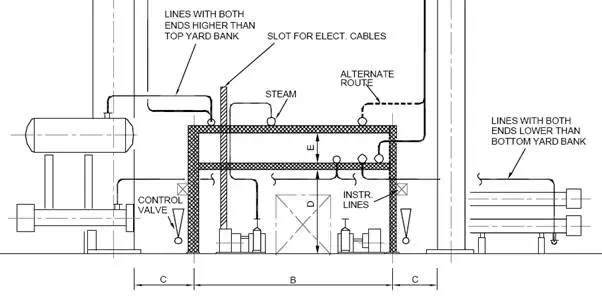

Piperack Elevation

Refer sketch for typical cross-section of piperack piping.

Elevation of yard piping is determined by the highest requirement of the following :

a) Headroom over a main road.

b) Headroom for access to equipment under the piperack.

c) Headroom under lines interconnecting the piperack and equipment outside the piperack.

The size of beam supporting the piperack piping should also be taken into account when

considering headroom.

Generally those process lines should be located in the top tier which interconnect two nozzles

elevated higher than the top tier. Process lines with one end lower than the bottom tier elevation can run either in the top or the bottom rack. If both ends of a process line are lower than the bottom tier elevation, the line should be located in the bottom tier.

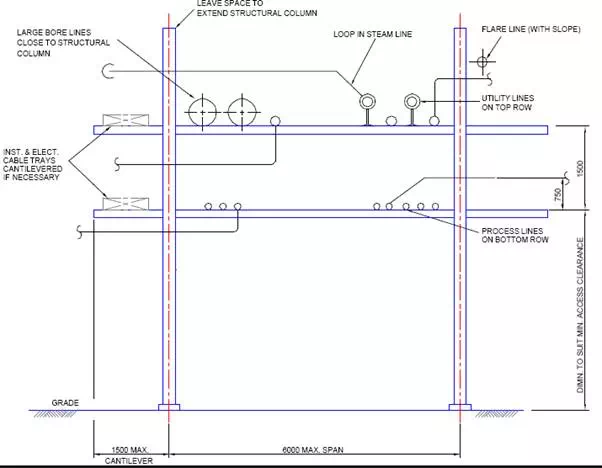

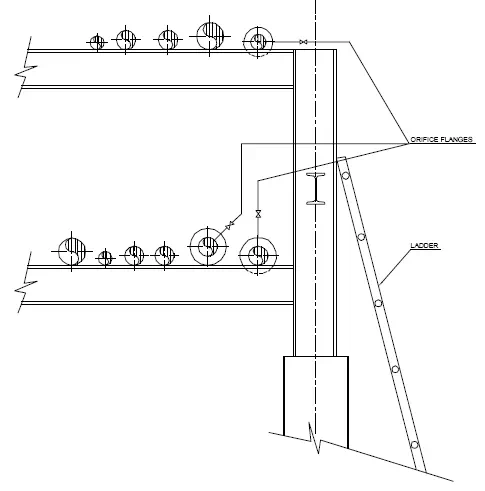

The elevation of a line can also be influenced by valves and instruments in the line. Often a more convenient access platform can be provided for valves arranged in the top tier of piperack. The preferred location of lines with orifice runs is near the edge of the piperack with orifice flanges near the column for more convenient protable ladder access. Refer sketch.

The sketch, upper right corner shows platform and walkway arrangements to valves, relief valves and instruments located in the piperack.

Piperack Piping Economy

The economy in piperack piping depends primarily on the length of lines arranged on the rack. Fittings, valves and instrument are relatively few in the piperack compared to pipe length.

Sketch shows those critical dimensions (A,B,C,D & E) which will influence piping cost from piperack piping layout point of view. These dimensions depend on the overall plant layout and should be carefully considered when the plot is developed.

Dimension 'A' is the total length of the piperack and is governed by the number and size of equipment, structure and buildings arranged along both sides of the piperack. On an average,

about 10 feet of rack length is required per process equipment (exchanger, drum, tower, unhoused compressor etc.)

A control room located along the rack will increase the piperack piping cost because all lines must pass by without really being associated with the relatively long control room.

To shorten piperack length (Dimension 'A'), various methods are applied viz. equipment in pairs, stacked exchangers, exchangers under elevated drums, drums or exchangers supported on towers with common platforms, drums supported on exchangers, process equipment located under the rack etc. These arrangements not only shorten the process interconnecting equipment directly but also shorten those lines which pass through this area and utility headers serving this area.