Auxiliary Equipment

Centrifugal and reciprocating compressors and their drives require a variety of auxiliary equipment to support their operation. The equipment for these compressors are discussed below.

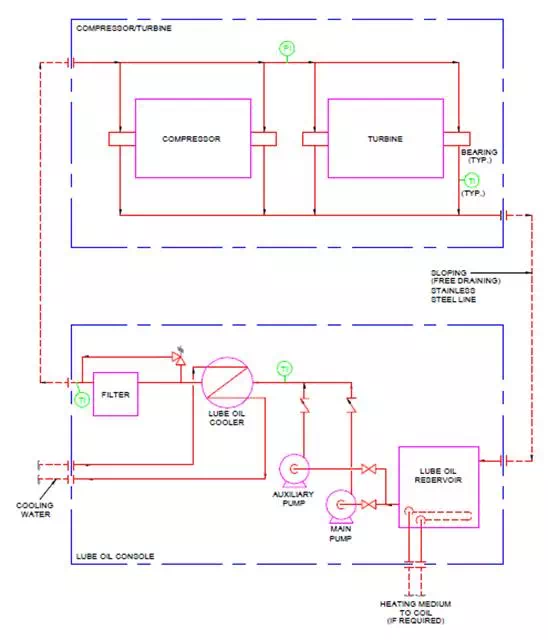

Lube Oil Consoles: Compressor bearings receive lubricating oil from the lube oil console. These consoles may be either stand alone or be mounted directly onto the compressor frame. The console consists of lube oil reservoir, oil filters, oil coolers and lube oil pumps.

Seal Oil Consoles:

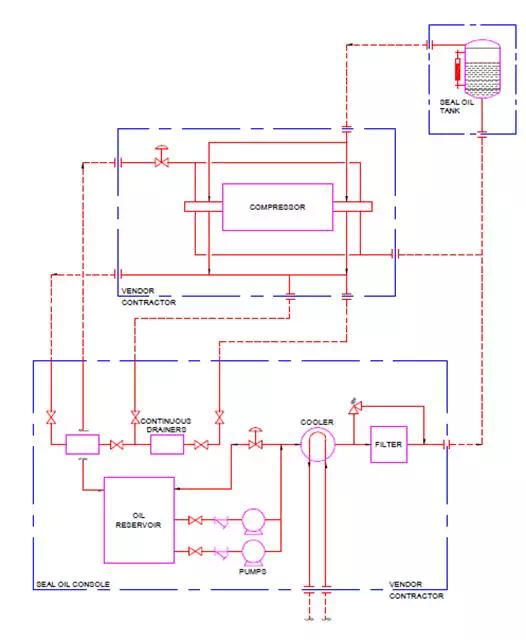

The hydraulic seals located at the outer ends of the compressor shaft receive oil from the sealoil console. The seal oil console consists of seal oil reservior, oil filters and main seal oil pumps.

Inlet Filters:

The inlet filters for air compressors are installed outside the building /shed at a level suitablefor clean air suction without any obstruction in the air flow. The vendor drawing of the filter shallbe reviewed for correct inlet/outlet ducting and the supporting arrangement.

Suction drum / knockout pot :

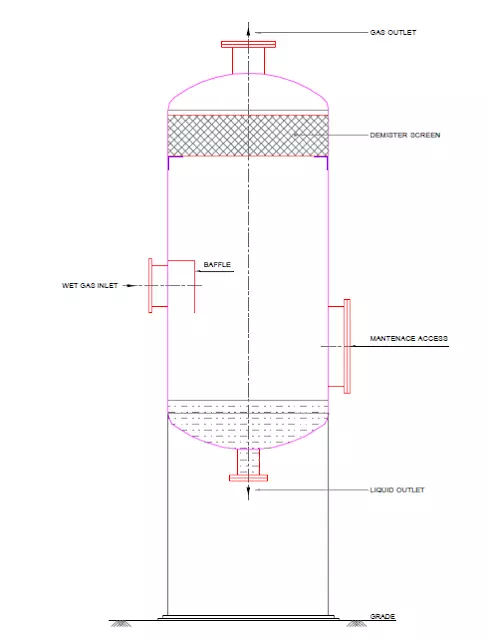

As compressors require dry gas free of foreign particles, it is necessary to pass inlet gas throughthe suction drum or knockout pot. This vessel removes moisture and particles from the gas bypassing it through a demister screen located just below the outlet nozzle.

Pulsation dampener / volume bottles:

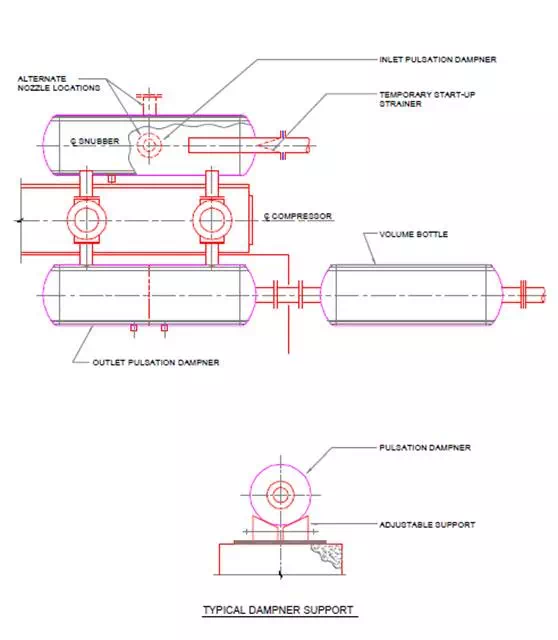

The negative effects of vibration on the life of reciprocating compressors and associatedpiping can be minimized by the use of pulsation dampeners (Refer Fig.CHP6). The pulsation dampeners are sized by the compressor vendor and are mounted directly on the cylindernozzles.

Volume bottles are used to reduce vibration. They are located downstream of the dischargepulsation dampener and are similar to snubbers without internal baffles or choke tubes.

PIPING ARRANGEMENT

The compressor house piping consists of suction / discharge piping, auxiliary equipment pipingand utility system piping. The main suction line with its components shall be as short anddirect as possible. The discharge line with its main components shall be routed clearing thecompressor and its driver and supported independent of compressor foundation or building column foundation. This will minimise the transmission of damaging vibrations to the building structure / frame.

The vendor furnishes that P&ID for the compressor with its auxiliary equipment. Thesedrawings should be reviewed fully for the provisions of vents and drains requirement of theinstallation.

For reciprocating compressors, API 618 provides the acceptance criteria for nozzleloads. For centrifugal compressors, API 617 provides the acceptance criteria fornozzle loads.

Reciprocating compressor piping arrangement should be finalized after analog study which identifies potentially damaging acoustic or pulsation problems during design phase itself.