Flexibility Calculation/Stress Analysis: Softwares Used and Data Required

Softwares available for flexibility calculation/stress analysis

Manual analysis has its limitation on the number and type of supports, the variation in temperature to which the system is subjected and the like. Hence solving a real live size problem is difficult or impossible by the manual methods.

There are number of softwares available to handle complex problems. The first computer analysis of the piping system was done in 1957. The flexibility analysis softwares available as on date are:

1. ADL PIPE

2. AUTO PIPE

3. CAE PIPE

4. CAE SAR II

5. PIPE PLUS

6. TRIFLEX

7. QFLEX

The pipe line geometry is feed into system along with the parameter such as the minimum operating temperatures, pipe sizes, bend radii type of branch connections, locations and type of supports. The analysis is done by Finite Element Method. Interpretation of the results to ensure economy, safety etc are the job by a real Piping Engineer.

Data required for flexibility calculations

The following data will be required for the flexibility calculations if it is carried out manually or by the use of software. It is therefore prudent to have this ready before starting.

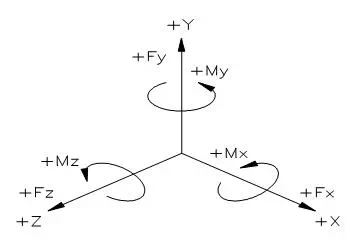

The direction of coordinates is fixed as below:

1. Code of Practice

2. Basic Material of Construction of Pipe

3. Ambient / Installation temperature

4. Number of Thermal Cases

5. Flexibility Temperature (See Note)

6. Design Pressure

7. Outside diameter of Pipe

8. Type of construction of pipe

9. Nominal Thickness of Pipe

10. Manufacturing tolerance

11. Corrosion allowance

12. Pipe Weight

13. Insulation Weight

14. Specific Gravity of Contents

15. Young’s Modulus at Ambient/Installation Temperature

16. Young’s Modulus at Flexibility Temperature

17. Thermal Expansion at Flexibility Temperature

18. Allowable stress at Ambient/ Installation temperature

19. Allowable stress at flexibility temperature

20. Bend radius and type of bend

21. Branch connection type

22. Weight of attachments – Valves and Specialties

23. Terminal movements with directions

Note:

The code states that the design temperature shall be assumed to be the same as fluid temperature unless calculations or test supports the use of other data.