Types of Loads Considered for Piping Stress Analysis

Every Piping system is subjected to different loads during its design life which develops stresses in the system. Depending on the stress design basis the system is classified as stress critical or non- stress critical. All the stress critical system shall be stress analyzed using software system (eg.Caesar II) to keep the stresses within the allowable limits as per the code/standard. The types of loads to be considered in Stress Analysis shall be as given in table:

Types of Loads:

a) Thermal

Loads at Various Operating Conditions

b) Sustained Loads

c) Seismic Loads

d) Wind Loads

e) PSV Reaction Force

f) Slug Force

g) Forces Induced by Surge Pressure

a) Thermal Loads at Various Operating Conditions

Analysis Temperature and Pressure to be used shall be as mentioned below.

Analysis Temperature

Normally the Design temperature (Maximum/ Minimum values as per Line List) shall be used for thermal analysis.

For those lines having Design temperature greater than 80 deg. C and if the difference between Operating and Design temperature is more than 25 deg. C, the maximum/minimum Operating temperatures, as obtained from Process Group, may be used in Stress Analysis in place of the Design temperature.

In addition to the Maximum/Minimum Design/Operating temperatures, Piping shall also be analyzed for the Normal Operating temperature.

Analysis Pressure

Line Design Pressure specified in the Line List shall be considered as the analysis pressure.

b) Sustained Loads

Sustained loads to be considered are as given below:

· Design pressure.

· Weight of Pipe and associated components such as Flanges, Valves, Strainer,

· Sight glass etc., mounted on the Piping System.

· Weight of Fluid/contents in the piping.

· Insulation and cladding weight.

· Hydro test loads, if applicable for the line.

c) Seismic Loads

For Projects where Seismic Design is to be carried out, equivalent Static Seismic Analysis method in Caesar II shall be used to evaluate the seismic stresses, displacements and loads on the piping system.

If the Seismic

coefficient is not provide by the client, then the calculation of static

seismic co-efficient in terms of g based on Project site-specific data shall

be calculated as per relevant codes (UBC/ASCE/SNIP/others as applicable). In

that case, the Seismic factor calculation document shall be enclosed as an

Attachment to the Project Stress Analysis Design basis document.

The normal Operating Temperature shall be used when analyzing for Occasional

loads. Seismic loads shall be considered as acting along the horizontal axes (both

in +ve and in the ve directions, that is, along North, South, East and West

directions), but not acting simultaneously.

d) Wind Loads

Wind loads shall be considered for lines with outside diameter 14 NB (including insulation) & above and at Elevation 10 meters & above from ground level. The normal Operating Temperature shall be used when analyzing for Occasional loads.

Wind shape factor

shall be considered as 0.7. Wind loads shall be considered as acting along the

horizontal axes (both in the +ve and in the ve directions, that is, along

North, South, East and West directions), but not acting simultaneously.

Wind pressure for the different Elevations shall be specific to the Project as

per the Project Civil/Structural design basis. The same shall be considered for

wind data input in piping analysis.

e) PSV Reaction Force

If the Piping System being analyzed consists of PSV (pressure safety valve), the reaction force due to PSV operation shall be considered as applicable and a static equivalent method of stress analysis shall be performed considering the same.

A Dynamic Load Factor equal to 2.0 shall be applied on the valve reaction force

value. However, in the case of valves of high reaction force values, the DLF value

calculated as per appendix-II of ASME B31.1 may be used, based on valve data if

provided by Vendor.

f) Slug Force

For lines having slug flow regime, as identified by the Process group on P&ID/line list, slug force shall be considered in the piping stress analysis. Slug force shall be calculated as below:

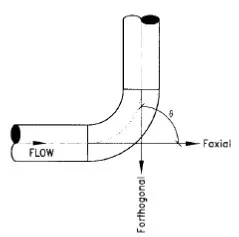

Fslug = (ρ) (A) (V2) [2(1 cos θ)]1/2 DLF

Where,

Fslug = Force due to slug in Newton.

ρ = Density of the slug in Kg/m3,

A = Inside area of pipe cross section in m2,

V = Velocity of moving slug in m/sec.

θ = inclusion angle at elbow or change of direction

DLF = Dynamic Load Factor (DLF) equal to two shall be used, unless more accurate value is available.

Fig1: Forces at a 90° bend (or 90° change in direction or at intersection)

Faxial = (ρ) (A) (V2) DLF

Forthogonal = (ρ) (A) (V2) DLF

Slug properties

shall be obtained from Process group.

Equivalent static analysis in Caesar-II shall be performed to simulate slug

loading in piping system, with the slug force calculated as above.

g) Forces Induced by Surge Pressure

The effect of surge on any line, as identified by the Process group or a specialist agency, shall be considered in piping analysis.

However two concurrent occasional loadings need not to be considered in piping stress analysis.