Flare System: Types, Segregation, Tips, Purge System and More

Flaring is defined as a process of controlled burning of exhaust gases which generates heat and noise. Flaring is a common practice in oil/gas exploration, production and processing operations. A flare system consists of a flare stack and pipes that feed gas to the stack. The type and amount of gas or liquids in the flare stack governs the sizing & brightness of the flare.

There are many function & reason for flaring, few reasons for flaring are:

1. During well production testing after drilling is completed

2. For safety and during emergencies and maintenance

3. For managing gas during compression and processing

4. Flaring at well sites to recover oil

1. Elevated Flare

2. Ground Flare

- Enclosed Flare

2. Open Flare

Elevated Flare

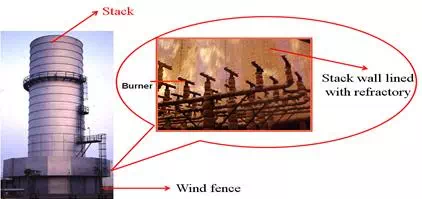

Enclosed Flare

Open Flare

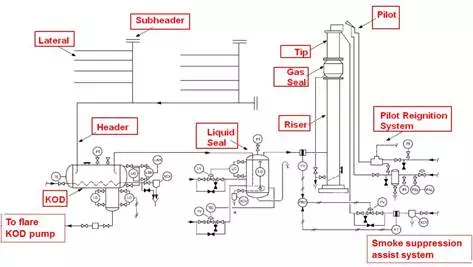

Click to enlarge figure Typical Flare System with Elevated Flare

2. Segregation of Flares

1. Service

- Acid gas flare

2. Cold dry flare

3. Warm wet flare

2. Pressure

1. Atmospheric

2. Low pressure

3. High pressure

1. Objective

1. Separate bulk liquid from gas

2. Limit liquid droplet size entrained with gas to the flare

3. Provide adequate residence time for liquid

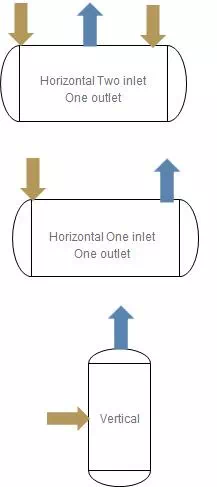

1. Sizing basis

1. Based on API 521

2. Separation of liquid droplet size of 300-600 microns considering the design case for the flare

3. 20-30 minutes of liquid hold-up time based on a relief case that results in maximum liquid

4. No internals to facilitate separation

5. Many orientations / options possible, horizontal KODs most preferred

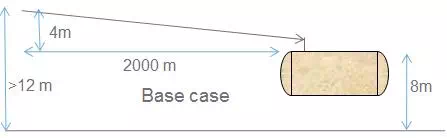

Flare KO Drum elevation

1. Flare Knock-Out Drum Elevation

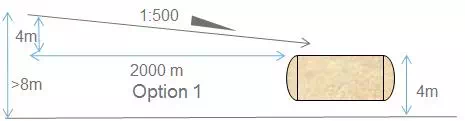

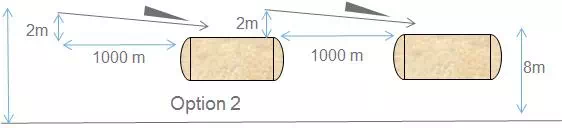

1. KO drum elevation decides pipe rack elevation based on 1:500 slope of main flare header

Flare KO Drum elevation

2. KO drum elevation determined by pump NPSH requirement

3. To reduce pipe rack elevation options are

4. Reduce KOD elevation (option 1)

1. Use vertical can pump

2. Locate pump within pit

3. Locate KO drum within pit

5. Use intermediate KO drums (option 2)

>Flare KO Drum elevation arrangement (Option 1)

Flare KO Drum elevation arrangement (Option 2)