Safety Relief Valve: A Pressure Relieving Device

1. Relief System

Pressure relief systems are an integral part of any process facility, from offshore production platforms to petrochemical complexes, and usually provide the last line of defense against overpressure and loss of containment.

The overpressure in the process system occurs during the below scenario:

1. Closed outlet on vessels

A. Inadvertent closing of manual valves

B. Fail close of ESDVís

1. Not intended opening of inlet valves

2. Check valve leaking or failing

3. Utility failure

4. Electrical or mechanical failures

A. System providing cooling

1. Loss of fans

A. Defects air-cooled heat exchangers

1. Loss of instrument air or electric instrument power

A. Control valves driven to the fail position

1. Heat exchanger tube failure

2. Transient pressure phenomenon

A. Water hammer

1. Hydraulic expansion

- Closed in liquids exposed to heat

1. Plant fires

2. Change in composition or chemical reactions

A. Entrance of volatile material into the system

2. API 521 Sizing Criteria

1. According to codes such as API 521 PSVís shall be installed to protect equipment in case of a fire.

2. It has been recognized by the industry that fire PSV may not prevent overpressure rupture in a fire and in some cases the PSV may not even open.

3. Still fire PSVís are installed, but they should not be considered primary protection against overpressure in a fire.

4. Primary protection is Blowdown, PFP and deluge

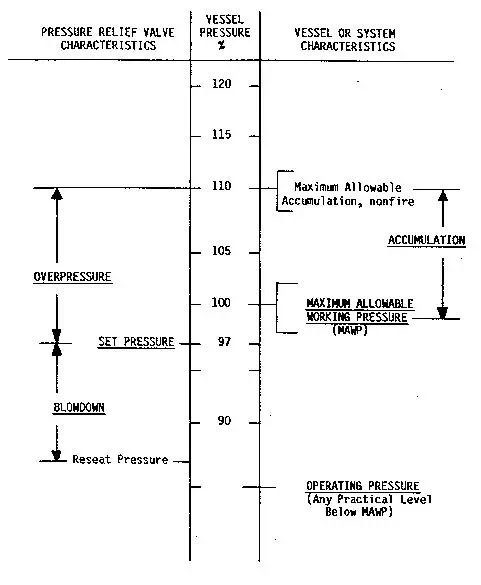

3. Relief System Ė Pressure Terminology

1. Operating pressure

2. MAWP

3. Design pressure

4. Set pressure

5. Accumulation

6. Overpressure

7. Blowdown

Relief System Ė Pressure Terminology

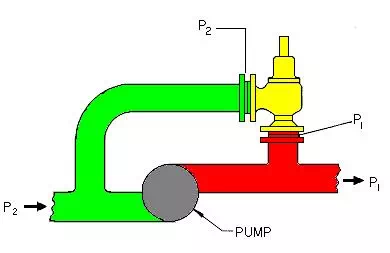

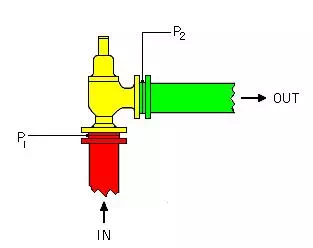

1. Superimposed Back Pressure

A. Pressure in discharge header before valve opens

B. Can be constant or variable

Superimposed Back Pressure

1. Built-up Back Pressure

A. Pressure in discharge header due to frictional losses after valve opens

B. Total = Superimposed + Built-up

Built-up Back Pressure

4. Code Requirements

1. General Code requirements include:

A. ASME Boiler & Pressure Vessel Codes

B. ASME B31.3 / Petroleum Refinery Piping

C. ASME B16.5 / Flanges & Flanged Fittings

1. All pressure vessels subject to overpressure shall be protected by a pressure relieving device

2. Liquid filled vessels or piping subject to thermal expansion must be protected by a thermal relief device

3. Multiple vessels may be protected by a single relief device provided there is a clear, unobstructed path to the device

4. At least one pressure relief device must be set at or below the MAWP

5. Relieving pressure shall not exceed MAWP (accumulation) by more than:

A. 3% for fired and unfired steam boilers

B. 10% for vessels equipped with a single pressure relief device

C. 16% for vessels equipped with multiple pressure relief devices

D. 21% for fire contingency

5. Pressure relieving methods

There are different methods through which the overpressure in the process can be relieved:

1. Flame arresters

3. Bursting discs

4. Blowdown valves