COMPACTION DRIVE AND RELATED PORE COMPRESSIBILITY PHENOMENA

The withdrawal of liquid or gas from a reservoir results in a reduction in the fluid pressure and consequently an increase in the effective or grain pressure, the latter being defined in Chapter 1, sec. 3, as the difference between the overburden and fluid pressures. This increased pressure between the grains will cause the reservoir to compact and this in turn can lead to subsidence at the surface. Various studies7,8,9,10 have shown that compaction depends only upon the difference between the vertically applied stress (overburden) and the internal stress (fluid pressure) and therefore, compaction can conveniently be measured in the laboratory by increasing the vertical stress on a rock sample while keeping the fluid pressure in the pores constant. If Vb is the bulk volume of a rock sample of thickness h, then the uniaxial compaction

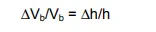

can best be determined in the laboratory using the triaxial compaction cell described by Teeuw11, which is shown in fig. 3.11 (a). The core sample, which is completely saturated with water, is contained in a cell which has permeable cap and base plates and a cylindrical, flexible sleeve surrounding it. Vertical stress is applied by means of a piston while the fluid pressure in the pores is maintained at one atmosphere. The pressure in the fluid surrounding the flexible sleeve can be increased independently so as to maintain the condition of

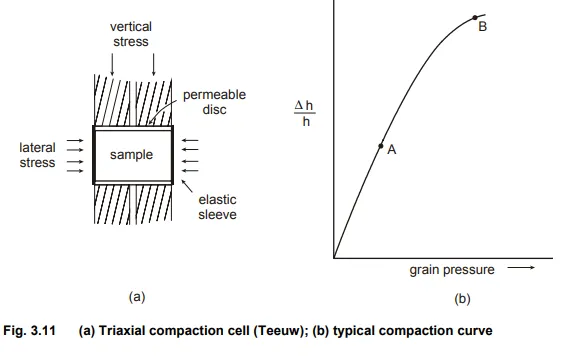

zero lateral strain on the sample. This pressure is continually adjusted so that any change in vertical thickness of the sample ∆h is uniformly related to the measured water expelled from the porous rock. If such an experiment were performed on an uncompacted sample of sand and the compaction ∆h/h plotted as a function of the applied vertical stress which, considering the fluid pressure is maintained at one atmosphere, is equivalent to the grain pressure, then the result would be as shown in fig. 3.11 (b). The slope of this curve, at any point, is

The characteristic shape of this compaction curve is intuitively what one would expect. At low grain pressures the compressibility of the uncompacted sample is very high since it is relatively easy to effect a closer packing of the grains at this stage. As the grain pressure increases, however, it becomes progressively more difficult to compact the sample further and the compressibility decreases. What is clear from such an experiment is that the bulk or pore compressibility of a reservoir is not constant but will continually change as fluids are withdrawn and the grain pressure increases. Under normal hydrostatic conditions, since both the overburden and water pressures increase linearly with depth, then so too does the grain pressure which is the difference between the two.

Thus a reservoir whose initial condition corresponds to point A will normally be buried at shallow depth, while a reservoir corresponding to point B will be buried deeper. Compaction drive is the expulsion of reservoir fluids due to the dynamic reduction of the pore volume and will only be significant as a drive mechanism if the pore compressibility cf is large. It therefore follows that such a drive mechanism will normally only provide a significant increase in the primary hydrocarbon recovery in shallow reservoirs. In parts of the Bachaquero field, Venezuela, as reported by Merle, et al12, the compaction drive mechanism accounts for more than 50% of total oil recovery.

This large reservoir dips between 1000−4000 ft. and has uniaxial compressibilities in excess of 100 × 10-6/psi. If the mechanics of reservoir compaction were as simple as described above, it would appear possible to derive a relationship between uniaxial compressibility and depth, for various types of typical reservoir rock, in an attempt to apply such a correlation universally. Unfortunately, the process of compaction is frequently irreversible which in turn implies that in-situ compressibility cannot be estimated in such a simple manner.

If the reservoir rock consists of well cemented grains in a rigid rock frame then the compaction, over a limited pressure range, will be approximately elastic and reversible. In loose unconsolidated sands, however, compaction is both inelastic and irreversible since upon each reloading cycle on such a sample, in a repeated loading experiment in a triaxial cell, it is possible for the individual grains to be packed in a different configuration than on the previous cycle and, in addition, some of the grains can suffer permanent mechanical deformation due to crushing.