COLLECTION OF FLUID SAMPLES

Samples of the reservoir fluid are usually collected at an early stage in the reservoir's producing life and dispatched to a laboratory for the full PVT analysis. There are basically two ways of collecting such samples, either by direct subsurface sampling or by surface recombination of the oil and gas phases.

Whichever technique is used the same basic problem exists, and that is, to ensure that the proportion of gas to oil in the composite sample is the same as that existing in the reservoir. Thus, sampling a reservoir under initial conditions, each stock tank barrel of oil in the sample should be combined with Rsi standard cubic feet of gas.

a) Subsurface sampling

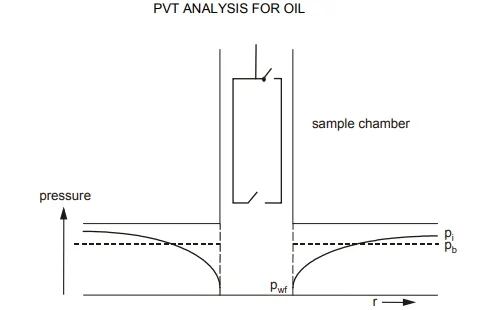

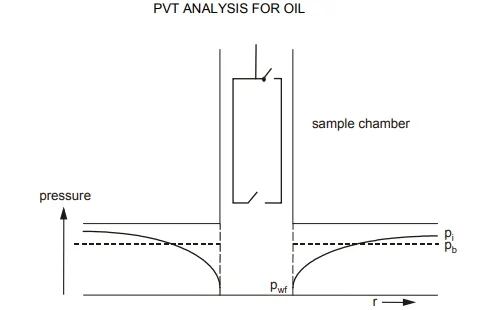

This is the more direct method of sampling and is illustrated schematically in fig. 2.6.

A special sampling bomb is run in the hole, on wireline, to the reservoir depth and the sample collected from the subsurface well stream at the prevailing bottom hole pressure. Either electrically or mechanically operated valves can be closed to trap a volume of the borehole fluids in the sampling chamber. This method will obviously yield a representative combined fluid sample providing that the oil is undersaturated with gas to such a degree that the bottom hole flowing pressure pwf at which the sample is collected, is above the bubble point pressure. In this case a single phase fluid, oil plus its dissolved gas, is flowing in the wellbore and therefore, a sample of the fluid is bound to have the oil and gas combined in the correct proportion. Many reservoirs, however, are initially at bubble point pressure and under these circumstances, irrespective of how low the producing rate is maintained during sampling, the bottom hole flowing pressure pwf will be less than the bubble point pressure pb as depicted in fig. 2.6. In this case, there will be saturated oil and a free gas phase flowing in the immediate vicinity of the wellbore, and in the wellbore itself, and consequently, there is no guarantee that the oil and gas will be collected in the correct volume proportion in the chamber.

b) Surface recombination sampling

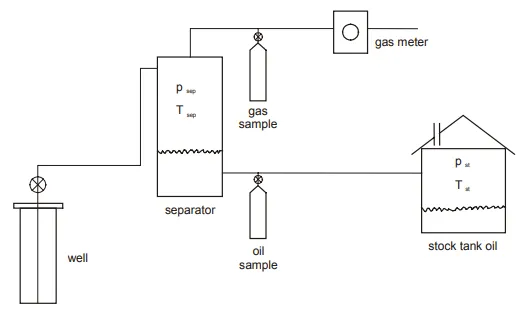

In collecting fluid samples at the surface, separate volumes of oil and gas are taken at separator conditions and recombined to give a composite fluid sample. The surface equipment is shown schematically in fig. 2.7.

Dimensionally, the measured gas oil ratio must be multiplied by the shrinkage factor from separator to stock tank conditions. This factor is usually determined in the laboratory as the first stage of a PVT analysis of a surface recombination sample by placing a small volume of the oil sample in a cell at the appropriate separator conditions and discharging it (flash expansion) to a second cell maintained at the field stock tank conditions. During this process some gas will be liberated from the separator sample, due to the reduction in pressure and temperature, and the diminished stock tank oil volume is measured, thus allowing the direct calculation of S. In order to be able to perform such an experiment it is important that the engineer should accurately measure the pressure and temperature prevailing at both separator and stock tank during sampling and provide the laboratory with these data.