Nodal analysis

Systems analysis has been used for many years to analyze the performance of systems composed of multiple interacting components. Gilbert[1] was perhaps the first to introduce the approach to oil and gas wells but Mach, Proano, and Brown and Brown popularized the concept, which is typically referred to as Nodal Analysis™ within the oil and gas industry. The objective of systems analysis is to combine the various components of the production system for an individual well to estimate production rates and optimize the components of the production system.

Necessity of examining flow through system

The flow of reservoir fluids from the subsurface reservoir to the stock tank or sales line requires an understanding of the principles of fluid flow through porous media and well tubulars. As the fluid moves through the production system, there will be an associated pressure drop to accompany the fluid flow. This pressure drop will be the sum of the pressure drops through the various components in the production system. Because of the compressible nature of the fluids produced in oil and gas operations, the pressure drop is dependent on the interaction between the various components in the system. This occurs because the pressure drop in a particular component is not only dependent on the flow rate through the component, but also on the average pressure that exists in the component.

As a result, the final design of a production system requires an integrated approach, since the system cannot be separated into a reservoir component or a piping component and handled independently. The amount of oil and gas produced from the reservoir to the surface depends on the total pressure drop in the production system, and the pressure drop in the system depends on the amount of fluid flowing through the system. Consequently, the entire production system must be analyzed as a unit or system.

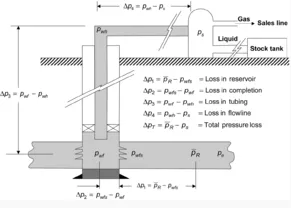

Depending on the terminal end of the production system, there is a total pressure drop from the reservoir pressure to the surface, as depicted in Fig. 1. If the separator represents the end of the production system, the total pressure drop in the system is the difference between the average reservoir pressure and the separator pressure:

Fig. 1—Production System and associated pressure losses.

....................(1)

....................(1)

This total pressure drop is then composed of individual pressure drops as the reservoir fluid flows to the surface. These pressure drops occur as the fluid flows through the reservoir and well completion, up the tubing, through the wellhead equipment and choke, and through the surface flowlines to the separator. Thus, the total pressure drop of Eq. 1 can be represented by Eq. 2.

....................(2)

....................(2)

These individual pressure drops can be divided into yet additional pressure drops to account for restrictions, subsurface safety valves, tubing accessories, etc.

Systems analysis is based on the concept of continuity. At any given point in the production system, there is a particular pressure and production rate associated with that point for a set of conditions. If there is any change in the system, then there will be an associated change in pressure and/or production rate at that same point. This concept allows the production system to be divided at a point of interest for evaluation of the two portions of the system. This evaluation determines the conditions of continuity of pressure and production rate at the division point, which is the estimated producing condition for the system being evaluated.

The approach provides the flexibility to divide the production system at any point of interest within the system to evaluate a particular component of the system. The most common division points are at the wellhead or at the perforations, either at the reservoir sandface or inside the wellbore. The terminal ends of the system will be the reservoir on the upstream end of the system and the separator at the downstream end of the system or the wellhead if a wellhead choke controls the well.

The components upstream of the division point or node comprise the inflow section of the system, while the components downstream of the node represent the outflow section. Once the system is divided into inflow and outflow sections, relationships are written to describe the rate-pressure relationship within each section. The flow rate through the system is determined once the conditions of continuity are satisfied:

· Flow into the division point equals flow out of the division point

· The pressure at the division point is the same in both inflow and outflow sections of the system

After the division point is selected, pressure relationships are developed for the inflow and outflow sections of the system to estimate the node pressure. The pressure in the inflow section of the system is determined from Eq. 3, while the outflow section pressure drop is determined from Eq. 4.

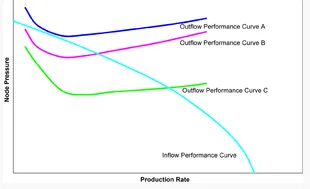

The pressure drop in any component, and thus in either the inflow or outflow section of the system, varies as a function of flow rate. As a result, a series of flow rates is used to calculate node pressures for each section of the system. Then, plots of node pressure vs. production rate for the inflow section and the outflow section are made. The curve representing the inflow section is called the inflow curve, while the curve representing the outflow section is the outflow curve. The intersection of the two curves provides the point of continuity required by the systems analysis approach and indicates the anticipated production rate and pressure for the system being analyzed.

Fig. 2 depicts a systems graph for a sensitivity study of three different combinations for outflow components labeled A, B, and C. For outflow curve A, there is no intersection with the inflow performance curve. Because there is no intersection, there is no continuity in the system and the well will not be expected to flow with System A. The inflow and outflow performance curves do intersect for System B. Thus this system satisfies continuity, and the well will be expected to produce at a rate and pressure indicated by the intersection of the inflow and outflow curves. System C also has an intersection and would be expected to produce at a higher rate and lower pressure than System B, as indicated by the graph.

Fig. 2—Inflow and outflow performance curves for systems analysis.

The outflow curve for System C has a rapidly decreasing pressure at low flow rates, reaches a minimum, and then begins to slowly increase with increasing rate. This is typical for many outflow curves, which, in some cases, will yield two intersection points with the inflow curve; however, the intersection at the lower rate is not a stable solution and is meaningless. The proper intersection of the inflow and outflow curves should be the intersection to the right of and several pressure units higher than the minimum pressure on the outflow curve.

The effect of changing any component of the system can be evaluated by recalculating the node pressure for the new characteristics of the system. If a change is made in an upstream component of the system, then the inflow curve will change and the outflow curve will remain unchanged. On the other hand, if a change in a downstream component is made, then the inflow curve will remain the same and the outflow curve will change. Both the inflow and outflow curves will be shifted if either of the fixed pressures in the system is changed, which can occur when evaluating the effects of reservoir depletion or considering different separator conditions or wellhead pressures.

Systems analysis may be used for many purposes in analyzing and designing producing oil and gas wells. The approach is suited for evaluating both flowing wells and artificial lift applications. The technique provides powerful insight in the design of an initial completion. Even with limited data, various completion scenarios can be evaluated to yield a qualitative estimate of expected well behavior. This process is very useful in analyzing current producing wells by identifying flow restrictions or opportunities to enhance performance.

Typical applications include:

· Estimation of flow rates

· Selection of tubing size

· Selection of flowline size

· Selection of wellhead pressures and surface choke sizing

· Estimation of the effects of reservoir pressure depletion

· Identification of flow restrictions

Other typical applications are:

· Sizing subsurface safety valves

· Evaluating perforation density

· Gravel pack design

· Artificial lift design

· Optimizing injection gas-liquid ratio for gas lift

· Evaluating the effects of lower wellhead pressures or installation of compression

· Evaluating well stimulation treatments

In addition, systems analysis can be used to evaluate multiwell producing systems. Systems analysis is a very robust and flexible method that can be used to design a well completion or improve the performance of a producing well.