Petroleum Production Optimization

Fundamentals

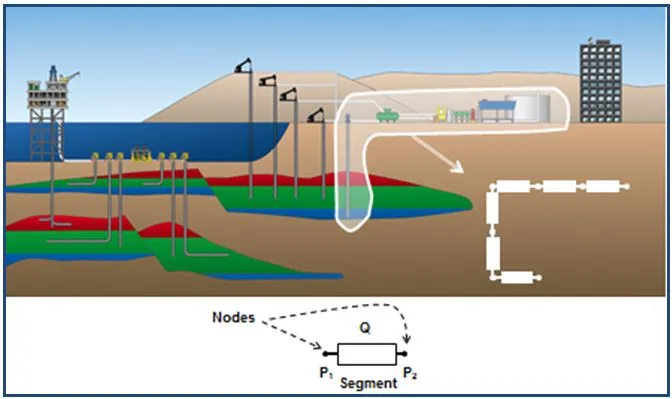

Production Optimization refers to the various activities of measuring, analyzing, modelling, prioritizing and implementing actions to enhance productivity of a field: reservoir/well/surface . Production Optimization is a fundamental practice to ensure recovery of developed reserves while maximizing returns. Production Optimization activities include:

Production Optimization, along with Reservoir Management, is a central part of a company’s field development and deliverability strategy. Key factor in production optimization is the capability to mitigate formation damage during well construction and production routine operations. Formation damage mitigation can be accomplished assuring that operational details are achieved before reaching the pay zone to the last production parameters recorded.

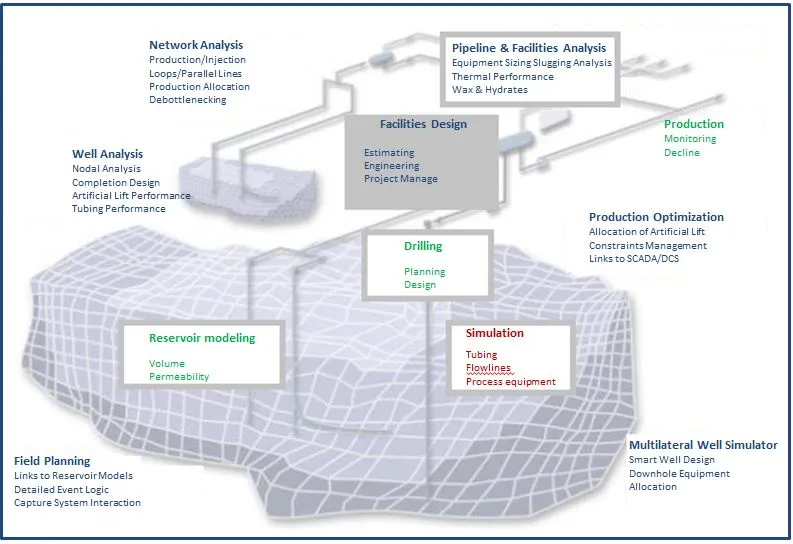

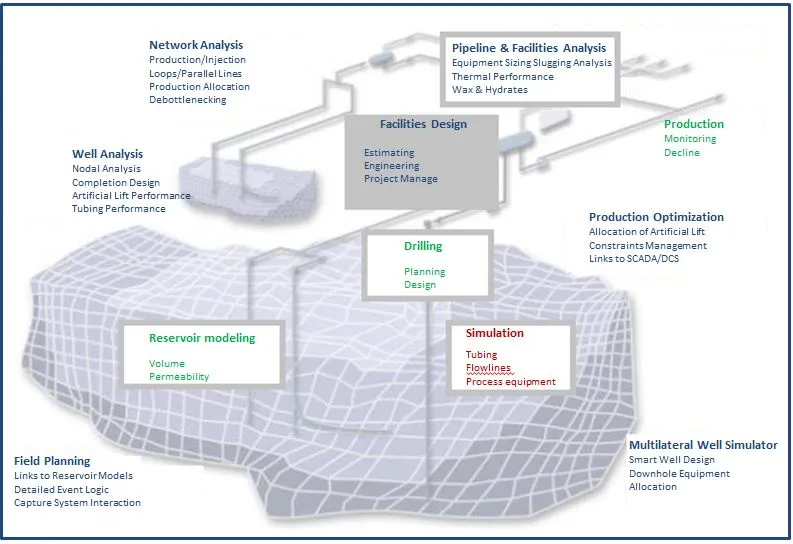

Various approaches to petroleum system production optimization

Technologies

Production optimization allows to increase productivity from existing field and uses encompass several areas of interest. In this context, contributes can come from the application of different technologies.

ADVANCED COMPLETION

Production optimization requires advanced and intelligent well completions.

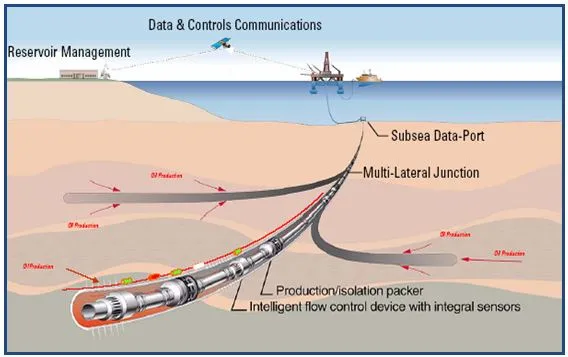

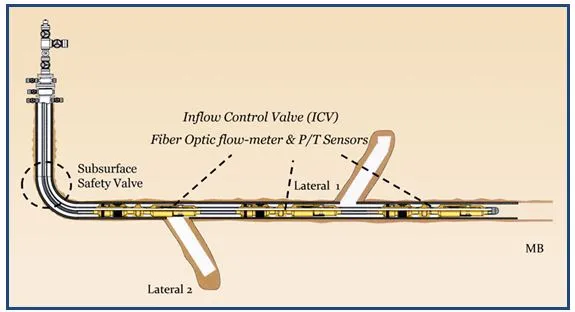

An Intelligent (Smart) completion is a well that contains a “Remotely Operated Adaptive Completion System” which provides real-time data and the capability to re-configure the well architecture without well interventions.

The system is able to collect, transmit, and analyze reservoir production data and to proof completion integrity, and to enable remote action to better control reservoir, well, and production processes.

These systems generate large amounts of real-time production data and the key challenge is to realize direct added value to operations with this data

Their primary objectives are to maximize or optimize production/recovery, minimize operating costs, and improve safety.

Intelligent well completion system

Intelligent completion for a multi lateral well

WELL PRODUCTIVITY

An ideal well productivity is the final goal of Production Optimization. In particular, well productivity is determined by a well inflow performance and in this context, a common approach is “Nodal Analysis”. It is a system analysis approach applied to analyze the performance of systems composed of interacting components.

Well Performance Analysis

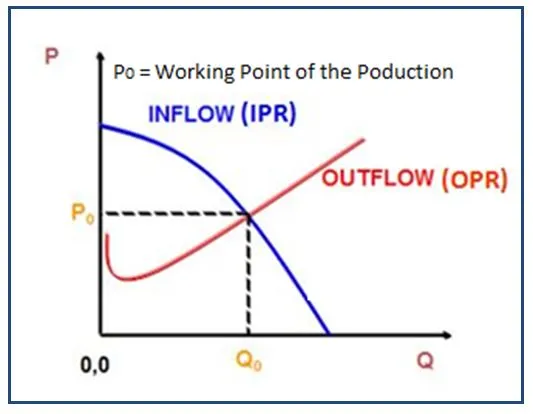

The Inflow Performance Relationship (IPR) is defined as the functional relationship between the inflow production rate and the inflowing pressure at node . The Outflow Performance Relationship (OPR) is defined as the functional relationship between the outflow production rate and the outflowing pressure at node. The interaction of IPR and OPR is the Working Point of the system.

IPR and OPR interaction

Productivity Index (PI or J) expresses the ability of a reservoir to deliver fluids to the wellbore. Optimal well productivity is achieved by the use of an integrated approach of disciplines and operations.

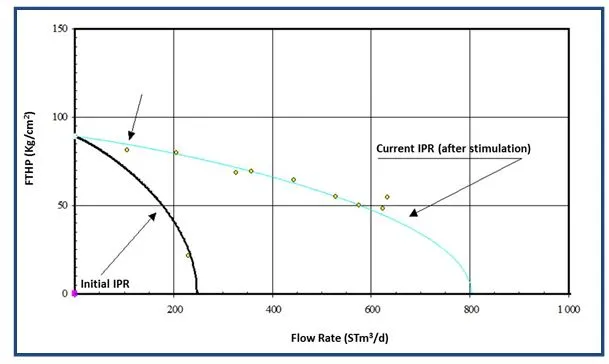

WELL STIMULATION

Well stimulation is a term describing a variety of operations performed on a well to improve its productivity. Stimulation operations can be focused on the wellbore or on the reservoir. They can be conducted on old wells and new wells and they can be also designed for remedial purposes. There are two main types of stimulation operations: matrix stimulation and hydraulic fracturing. Matrix stimulation is performed below the reservoir fracture pressure in an effort to restore the natural permeability of the reservoir rock. Well matrix stimulation is achieved by pumping acid mixtures (acidizing) into the near-wellbore area to dissolve the limestone and dolomite formations or the formation damage particles between the sediment grains of the sandstone rocks. Hydraulic fracturing is the most common mechanism for increasing well productivity.

Hydraulic fracturing id used to by-pass near wellbore damage and Increase well production by changing flow regime from radial to pseudo-linear, to reduce sand production and to increase access to the reservoir from the well bore.

Graphical representation of IPR under different conditions

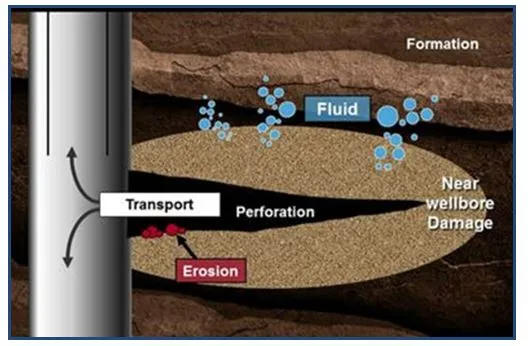

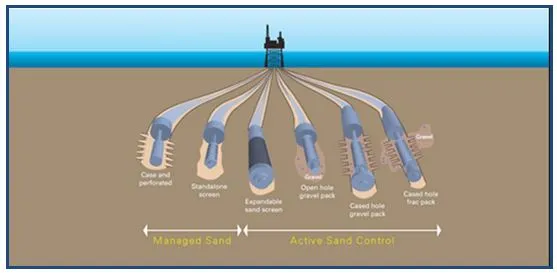

SAND CONTROL MANAGEMENT

When oil is produced from relatively weak reservoir rocks, small particles and sand grains are dislodged and carried along with the flow. This sand production can create erosion in flowlines and other equipment. Sand management can be considered as a key issues in field development in most of world’s oil and gas fields. Sand control management can be counted as an activity which shares risks (safety, environmental, process and cost) of producing sand to the surface vs. the risks of trying to keep it down in the reservoir using different mechanical or chemical control techniques.

Step process for sanding

Methods of sand control

Softwares

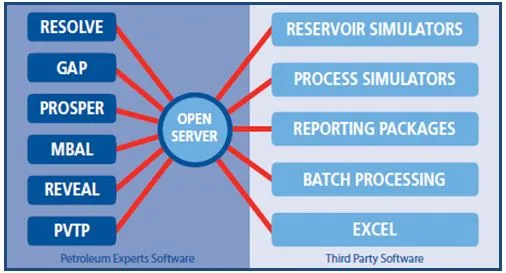

Computer Simulations software provide geoscientists and engineers with insights into the behavior of the well under changing conditions. The simulations have moved on from their ‘run’ on time consuming and expensive supercomputers to faster and cost effective intelligent platforms. New systems provide more accurate results, better understanding of extractable reserves enabling timely reactions to ever changing market conditions and significantly lower total cost. Some of the most popular software suits are briefly described below. IPM- PETREX The IPM suite Integrated Production Modelling – is developed by Petroleum Experts (Petex). IPM model is an oil or gas production system which includes reservoir, wells and the surface network. The following table give a synthetic description of production models:

Integrated Production Modelling

Open Server Communication

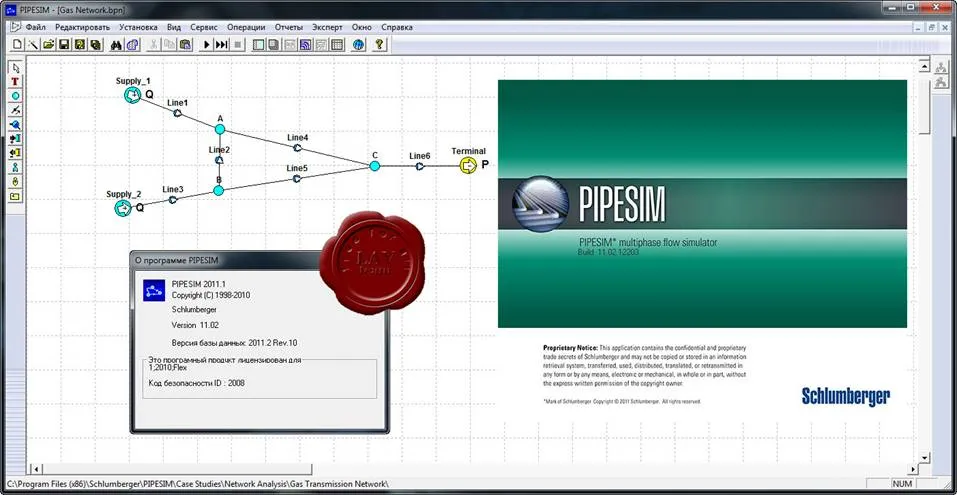

IPM allows the integration with the reservoir simulation models – Eclipse, VIP, etc. – to evaluate the impact on production. PIPESIM- SCHLUMBERGER PIPESIM is a flow simulator that can create well models to help increase production and understand reservoir potential. PIPESIM simulator models multiphase flow from the reservoir to the wellhead and considers artificial lift systems, including rod pumps, ESP, and gas lift. PIPESIM enables to

PIPESIM includes all the standard completion model types for vertical, horizontal, and fractured wells, and allows for complex multilayered completions using a wide variety of reservoir inflow parameters and fluid descriptions.

Gas Transmission Network – Case study

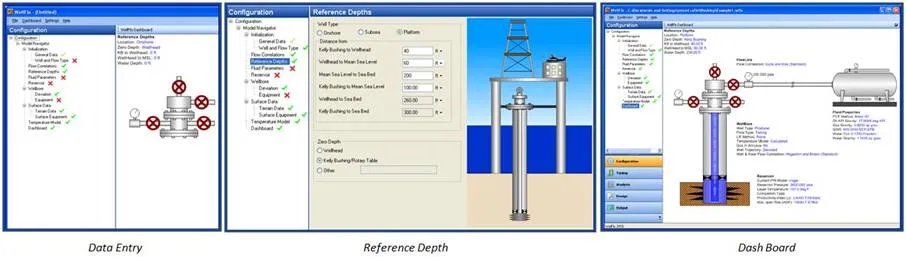

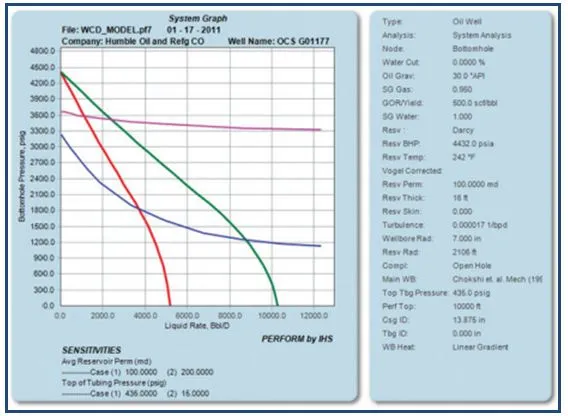

PERFORM – IHS

PERFORM is well-performance software standard for NODAL and well analysis allowing to gain understanding of flow in each component of a well, cutting costs and maximizing production. PERFORM allows to model well production performance, including downhole networks for multilayer and multilateral wells, different completion types, horizontal, deviated wellbore, fractured and non-fractured formations. It also allows calculations of coiled tubing, velocity strings, gaslift, and flow assurance.

Detailed Interface displays both input and output parameters

Well System analysis (NODAL) plot

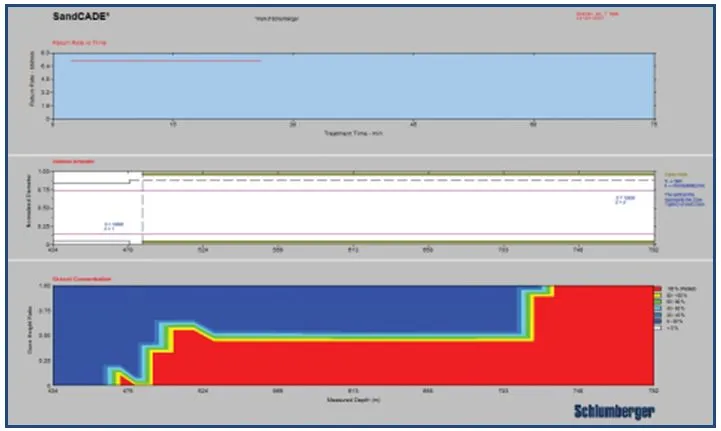

SAND MANAGEMENT SOFTWARE – SCHLUMBERGER

Sand CADE is a gravel-pack design and evaluation software Sand CADE software performs engineering calculations to assess the sand control treatment design and supports job execution and evaluation for open-hole and cased-hole gravel-pack completions.

Sand Advisor Software supports screen and gravel selection in open-hole applications by analyzing the formation particle-size distributions.

SandCADE horizontal openhole gravel placement simulation