Nuclear magnetic resonance (NMR) logging

Nuclear magnetic resonance (NMR) has been, and continues to be, widely used in chemistry, physics, and biomedicine and, more recently, in clinical diagnosis for imaging the internal structure of the human body. The same physical principles involved in clinical imaging also apply to imaging any fluid-saturated porous media, including reservoir rocks. The petroleum industry quickly adapted this technology to petrophysical laboratory research and subsequently developed downhole logging tools for in-situ reservoir evaluation.

Purpose of NMR logging

NMR logging, a subcategory of electromagnetic logging, measures the induced magnet moment of hydrogen nuclei (protons) contained within the fluid-filled pore space of porous media (reservoir rocks). Unlike conventional logging measurements (e.g., acoustic, density, neutron, and resistivity), which respond to both the rock matrix and fluid properties and are strongly dependent on mineralogy, NMR-logging measurements respond to the presence of hydrogen protons. Because these protons primarily occur in pore fluids, NMR effectively responds to the volume, composition, viscosity, and distribution of these fluids, for example:

· Oil

· Gas

· Water

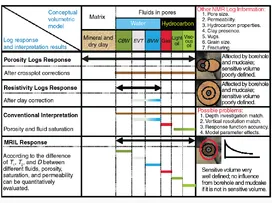

NMR logs provide information about the quantities of fluids present, the properties of these fluids, and the sizes of the pores containing these fluids. From this information, it is possible to infer or estimate (Fig.1):

· The volume (porosity) and distribution (permeability) of the rock pore space

· Rock composition

· Type and quantity of fluid hydrocarbons

· Hydrocarbon producibility

Fig.1 – NMR logging-tool response compared to conventional logging tools. NMR porosity is independent of matrix minerals, and the total response is very sensitive to fluid properties. Differences in relaxation times and/or fluid diffusivity allow NMR data to be used to differentiate clay-bound water, capillary-bound water, movable water, gas, light oil, and viscous oils. NMR-log data also provide information concerning pore size, permeability, hydrocarbon properties, vugs, fractures, and grain size.

NMR logging provides measurements of a variety of critical rock and fluid properties in varying reservoir conditions (e.g., salinity, lithology, and texture), some of which are unavailable using conventional logging methods (Fig.1) and without requiring radioactive sources (Table 1). Whether run independently as a standalone service or integrated with conventional log and core data for advanced formation and fluid analyses, NMR logging has significantly contributed to the accuracy of hydrocarbon-reservoir evaluation. During the past decade, a new generation of wireline-logging devices has been introduced into commercial service. In the past few years, logging-while-drilling (LWD) devices and downhole NMR spectrometers have also been introduced.

Table 1

Whether used as a standalone service or in combination with other logs and core data, NMR logs can provide an improved understanding of reservoir petrophysics and producibility. However, NMR logs are the most complex logging service introduced to date and require extensive prejob planning to ensure optimal acquisition of the appropriate data needed to achieve the desired objectives.

Historical development

Within a few years after the first successful observations of NMR in 1946, and the demonstration of free-precession NMR in the earth’s magnetic field in 1948, the petroleum industry recognized the potential of NMR measurements for evaluating:

· Reservoir rocks

· Pore fluids

· Fluid displacement (flow)

In the early 1950s, several companies—particularly California Research (Chevron), Magnolia (Mobil), Texaco, Schlumberger, and Shell—began extensive investigations to understand the NMR properties of fluids in porous media for the purpose of characterizing reservoir rocks (porosity, permeability, and fluid content).[1][2][3] In addition to laboratory research, these investigations included proposals for logging devices and the development of well-logging methods to permit formation evaluation in situ.[1][4] Although a number of patents for logging tools were issued in the 1950s, it was not until Chevron completed an experimental Earth’s field nuclear-magnetic-log (NML) logging device in 1958 that a functioning device was actually developed.[1][5] Limited commercial service of these devices was introduced in 1962 by Atlas, using the Chevron centralized design, and followed in 1965 by Schlumberger, using a pad-type tool of its own design. An improved version of the Schlumberger tool was introduced in 1978. Although the potential applications for this measurement were significant, particularly in the shallow, heavy-oil fields of the San Joaquin Valley,[6] in general, they did not live up to expectations and were not commercially successful.[7] Tool reliability and operational limitations proved to be major obstacles:

· The tool was not combinable, it required high (surface) power

· The signal level varied geographically and was generally very low as a result of the low-operational frequency (2 kHz)

· The borehole had to be doped with powdered magnetite to suppress the proton signal from the mud.[1][2][8]

The final version of the Schlumberger NML tool—a centralized tool introduced in 1984—proved reliable and commercially successful and was in service until the advent of modern pulse-echo tools in 1994.

In 1978, the Los Alamos Natl. Laboratory developed a logging tool that employed permanent magnets and used a pulsed radio frequency (RF) (pulse-echo) NMR method. Although this particular design had serious limitations—such as a low signal-to-noise ratio (S/N) that prohibited continuous, nonstationary logging—the concept set the stage for the development of modern commercial NMR tools. This advance was soon followed by improvements in magnet and coil design that enabled continuous logging. During the 1980s, while developing a commercial logging tool, industry also carried out laboratory experiments to further understand NMR behavior in fluid-filled porous media and to develop petrophysical interpretations from these data. Ultimately, two wireline tools using different magnet and coil configurations emerged from these efforts:

· Numar’s mandrel device (MRIL)

· Schlumberger’s skid (sometimes called "pad") design [combinable magnetic resonance (CMR) tool]

Commercial logging began with these tools in 1991 and 1995, respectively. These wireline-tool designs continue to evolve (see section on Tool Design in this chapter). Recent improvements allow simultaneous acquisition of more measurements, operation in a wider range of borehole conditions, and faster logging speeds. Detailed accounts of the historical development of NMR and NMR logging are available in several published references.[4][9][10][11]

In addition to improvements in wireline tools, new acquisition schemes and processing methods have improved the resolution, quality, and utility of the acquired data and enabled enhanced interpretation methods and data analysis. Concurrent with wireline improvements, LWD NMR logging services were being developed and have been introduced in the past few years. In a related development, a downhole NMR spectrometer is now available for use with a formation-testing tool for in-situ fluid analysis.