Pipe Material

Piping components are used to transporting various liquids that can be Flammable, Corrosive, Explosives, Volatile, Reactive and sometime Hazardous to human health that is why selection of proper pipe material is important.

Process Conditions for Pipe Material Selection

Piping material selection mainly depends on process conditions such as

§ Fluid it transports;

§ at what temperature

§ at what pressure it transports.

Let’s try to understand this condition in depth.

1st, Process condition that will impact the selection of material is type of fluid it transport. For corrosive fluids, you have to go for higher corrosion resistance material as compared to non-corrosive service

§ Corrosive fluids such as – crude oil, Sea Water, H2S, Ammonia, Acids etc. required high corrosion resistance material.

§ On the other hand, normal carbon steel is enough for Non-Corrosive fluids such as – Lube oil, Air, Nitrogen etc.

2nd Process condition that will impact the selection of material is the Temperature of fluids

§ Cryogenic

§ Low temperature

§ Medium temperature

§ High temperature

Increase or decrease in the service fluid temperature will greatly affect mechanical properties of the pipe material such as impact resistance, elongation, and tensile strength; hence, you required special material for both high temperature & Cryogenic services.

3rd Process condition that will impact the selection of material is the Pressure of service fluids. You required high strength material or higher thickness material for high-pressure services compare to normal pressure services.

Others non-process factor that also considered during material selection are

§ Cost of material

§ Availability – whether the material is locally available or import is required.

§ Weldability and Manufacturability of material also play a vital role in selection. Preference is always given to the material which does not require any special requirement during welding and manufacturing.

Material Properties

Similar to process fluid properties, there are certain material properties that also consider while selecting pipe material. Some of them are

§ Ultimate Tensile Strength – that is the capacity of a material to withstand when subjected to tension.

§ Yield Strength – that is the load at which plastic deformation or you can say permanent deformation start.

§ Elasticity – is the ability of a material to resume its normal shape after the load is removed just like rubber.

§ % Elongation – Percent elongation is a measure of ductility.

§ Hardness – is ability of a material to resist plastic deformation.

§ Toughness – ability of a material to absorb energy before fracture.

§ Creep resistance – ability to resist any kind of distortion when under a load over an extended period.

§ Fatigue Resistance – is ability of material to withstand cyclic load for a given number of cycles before it fails.

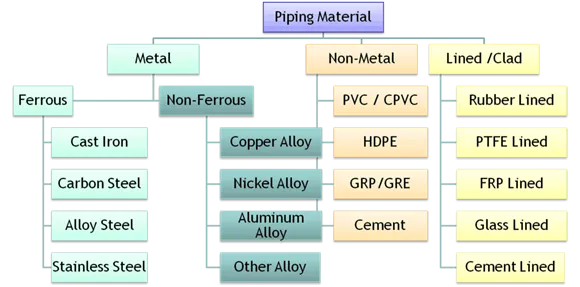

Now considering both process and material property you can choose piping material from a verity of material available. In this chart, I have listed different types of material that used in process piping to meet various design condition. Piping material broadly classified into three categories. Metal, Nonmetal, and composite, which is a combination of metal to metal or metal to non-metal.

Ferrous Metal

1. Carbon Steel

2. Alloy Steel

3. Stainless Steel

Non-Ferrous Metal

1. Copper and Copper Alloys

2. Nickel and Nickel Alloys

3. Aluminum and Aluminum Alloys

4. Titanium and Titanium Alloys

5. Zirconium and Zirconium Alloys

Non-Metal

1. PVC/CPVC

2. HDPE

3. GRE/GRP

4. Cement pipes