Pipelines Installations

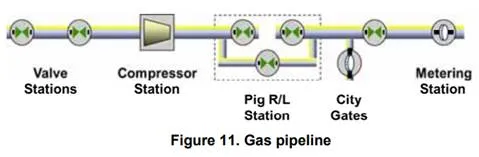

Pipeline installations consist of driving compressors and pumps, valve stations, pig receive/launch facilities, where the pig is used for cleaning or inspecting the pipeline. A pipeline SCADA system and pipeline management system is required to control and operate the pipeline.

Pipeline terminal

Pipelines transport gas or liquid, and are fed from the high pressure compressors or pumps. The pipeline terminal includes termination systems for the pipeline. A pig launcher and receiver is a minimum requirement, allowing insertion of a pipeline pigging device used to clean or inspect the pipeline on the inside. Essentially, it is a large chamber that can be pressurized and purged to insert and remove the pig or scraper without depressurizing the pipeline.

The pig is often driven by pipeline flow, either directly or through a pump or turbine arrangement that also drives wheels that roll against the walls and mechanisms to rotate brushes and other scraping mechanisms. Intelligent pigs also contain instrumentation for remote control and cameras, etc.

Gas Pipelines, compressor and valve stations

One or more compressor stations are needed to keep the required gas flow in the pipeline. Internal friction will cause a pressure drop along the pipeline that increases with flow. Thus, the starting pressure must be high enough to maintain design capacity flow up to the final terminal. If this is not practically possible, additional compressor stations are needed along the total length. Typical starting pressure is about 150-250 bar (15-25 MPa). The final pressure can be as low as 50 bar (5 MPa) at the pipeline terminal end.

As an example, about 150 MW in compressor power is required to transport 70 mill scm/day though the 1166 km Langeled pipeline with a starting pressure of 250 Ormen Lange Nyhamna. The initial section is 42 in, which increases to 44 in at Sleipner, a little more than halfway (627 km from Nyhamna, 540 km from Easington, UK), where the intermediate pressure is 155 bar maximum.

The 1200 km Northstream pipeline from Russia (Portovaya, Vyborg) to Germany (by Hannover), has two parallel pipes of almost the same dimensions, pressure and compression power each as Langeled.

Block valve stations (or vine valve stations) are required to allow closure of off flow at regular intervals to limit accidental release of gas in case of pipeline rupture. This will be determined by the maximum permissible released gas volume. A valve station is normally operated by remote telemetry and in addition to the closing valve, at least contains pressure, temperature and some level of flow measurement. These will feed back into the pipeline modelling system. Even if methane (CH4) is lighter than air and will rapidly rise, other gases such as propane (C3H8) are present in up to 8% by volume, and are heavier than air. They will sink, and rapidly create a large volume of combustible gas mixture.

In cases where multiple producers and pipelines feed into a larger pipeline grid, the pressure balancing to maintain required flow and observe contractual volume allocations back to individual production sites presents additional challenges for the pipeline balancing system.