Heat exchangers

For the compressor to operate efficiently, gas temperature should be low. The lower the temperature, the less energy will be used to compress the gas for the given final pressure and temperature. However, both gas from separators and compressed gas are relatively hot. When gas is compressed, it must remain in thermodynamic balance, which means that the gas pressure times the volume over the temperature (PV/T) must remain constant. (PV = nkT). This ends up as a temperature increase.

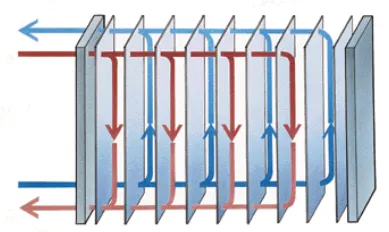

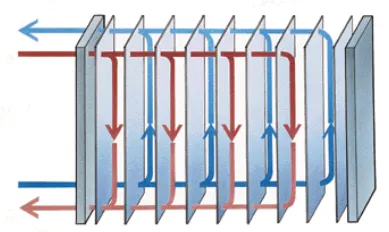

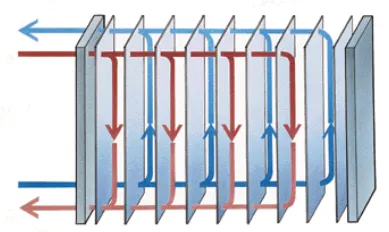

Heat exchangers of various forms are used to cool the gas. Plate heat exchangers (upper picture) consist of a number of plates where the gas and cooling medium pass between alternating plates in opposing directions. Tube and shell exchangers (next picture) place tubes inside a shell filled with cooling fluid. The cooling fluid is often pure water with corrosion inhibitors.

When designing the process, it is important to plan the thermal energy balance. Heat should be conserved, e.g., by using the cooling fluid from the gas train to reheat oil in the oil train. Excess heat is dispersed, e.g., by seawater cooling. However, hot seawater is extremely corrosive, so materials with high resistance to corrosion, such as titanium must be used.