Water treatment

On an installation such as this, where the water cut is high, there will be a huge amount of water produced. In our example, a water cut of 40% gives water production of about 4,000 cubic meters per day (4 million liters) that must be cleaned before discharge to sea. Often, this water contains sand particles bound to the oil/water emulsion.

The environmental regulations in most countries are quite strict. For example, in the Northeast Atlantic, the OSPAR convention limits oil in water discharged to sea to 40 mg/liter (ppm).

It also places limits on other forms of contaminants. This still means that the equivalent of up to one barrel of oil per day in contaminants from the above production is discharged into the sea, but in this form, microscopic oil drops are broken down quickly by natural bacteria.

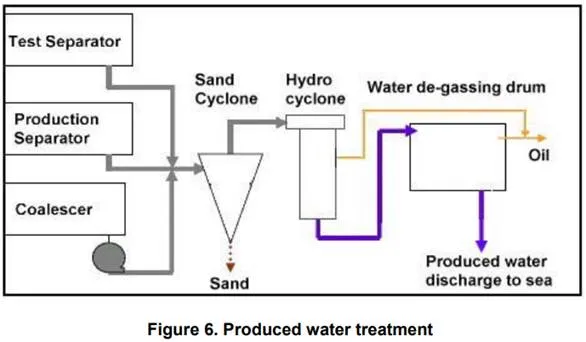

Various pieces of equipment are used. This illustration shows a typical water treatment system. Water from the separators and coalescers first goes to a sand cyclone, which removes most of the sand. The sand is further washed before it is discharged.

The water then goes to a hydrocyclone, a centrifugal separator that removes oil drops. The hydrocyclone creates a standing vortex where oil collects in the middle and water is forced to the side.

Finally, the water is collected in the water de-gassing drum. Dispersed gas slowly rises and pulls remaining oil droplets to the surface by flotation. The surface oil film is drained, and the produced water can be discharged to sea. Recovered oil in the water treatment system is typically recycled to the third stage separator.

Gas treatment and compression

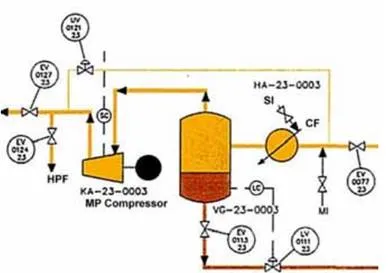

The gas train consists of several stages, each taking gas from a suitable pressure level in the production separator's gas outlet, and from the previous stage.

A typical stage is shown. Incoming gas (on the right) is first cooled in a heat exchanger. It then passes through the scrubber to remove liquids and goes into the compressor. The anti-surge loop (thin orange line) and the surge valve (UV0121 23) allow the gas to recirculate. The components are described below.