Exploration and drilling

When 3D seismic investigation has been completed, it is time to drill the well. Normally, dedicated drilling rigs either on mobile onshore units or offshore floating rigs are used. Larger production platforms may also have their own production drilling equipment.

The main components of the drilling rig are the derrick, floor, drawworks, drive and mud handling. Control and power can be hydraulic or electric.

Earlier pictures of drillers and roughnecks working with rotary tables (bottom drives) are now replaced with top drive and semiautomated pipe handling on larger installations. The hydraulic or electric top drive hangs from the derrick crown and gives pressure and rotational torque to the drill string. The whole assembly is controlled by the drawworks.

The drill string is assembled from pipe segments about 30 meters (100 feet) long, normally with conical inside threads at one end and outside at the other. As each 30 meter segment is drilled, the drive is disconnected and a new pipe segment inserted in the string. A cone bit is used to dig into the rock. Different cones are used for different types of rock and at different stages of the well. The picture above shows roller cones with inserts (on the left). Other bits are PDC (polycrystalline diamond compact, on the right) and diamond impregnated.

The drill string is assembled from pipe segments about 30 meters (100 feet) long, normally with conical inside threads at one end and outside at the other. As each 30 meter segment is drilled, the drive is disconnected and a new pipe segment inserted in the string. A cone bit is used to dig into the rock. Different cones are used for different types of rock and at different stages of the well. The picture above shows roller cones with inserts (on the left). Other bits are PDC (polycrystalline diamond compact, on the right) and diamond impregnated.

As the well is sunk into the ground, the weight of the drill string increases and might reach 500 metric tons or more for a 3,000 meter deep well. The drawwork and top drive must be precisely controlled so as not to overload and break the drill string or the cone. Typical values are 50kN force on the bit and a torque of 1-1.5 kNm at 40-80 RPM for an 8-inch cone. Rate of penetration (ROP) is very dependent on depth and could be as much as 20m per hour for shallow sandstone and dolomite (chalk), and as low as 1m per hour on deep shale rock and granite.

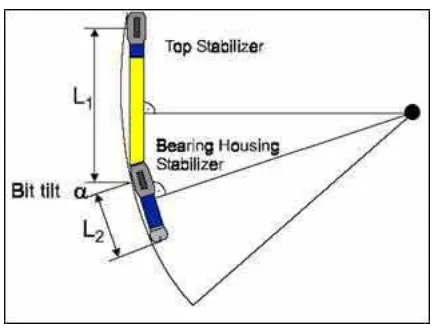

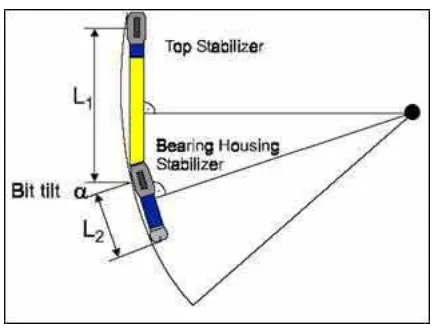

Directional drilling is intentional deviation of a well bore from the vertical. It is often necessary to drill at an angle from the vertical to reach different parts of the formation. Controlled directional drilling makes it possible to reach subsurface areas laterally remote from the point where the bit enters the earth. It often involves the use of a drill motor driven by mud pressure mounted directly on the cone (mud motor, turbo drill, and dyna-drill), whipstocks – a steel casing that bends between the drill pipe and cone, or other deflecting rods, also used for horizontal wells and multiple completions, where one well may split into several bores. A well that has sections of more than 80 degrees from the vertical is called a horizontal well. Modern wells are drilled with large horizontal offsets to reach different parts of the structure and achieve higher production. The world record is more than 15 km. Multiple completions allow production from several locations.

Wells can be of any depth from near the surface to a depth of more than 6,000 meters. Oil and gas are typically formed at 3,000-4,000 meters depth, but part of the overlying rock may have since eroded away. The pressure and temperature generally increase with increasing depth, so that deep wells can have more than 200 ºC temperature and 90 MPa pressure (900 times atmospheric pressure), equivalent to the hydrostatic pressure set by the distance to the surface. The weight of the oil in the production string reduces wellhead pressure. Crude oil has a specific weight of 790 to 970 kg per cubic meter. For a 3,000 meter deep well with 30 MPa downhole pressure and normal crude oil at 850 kg/m3 , the wellhead static pressure will only be around 4.5 MPa. During production, the pressure will drop further due to resistance to flow in the reservoir and well.

The mud enters though the drill pipe, passes through the cone and rises in the uncompleted well. Mud serves several purposes:

v It brings rock shales (fragments of rock) up to the surface

v It cleans and cools the cone

v It lubricates the drill pipe string and cone

v Fibrous particles attach to the well surface to bind solids

v Mud weight should balance the downhole pressure to avoid leakage of gas and oil. Often, the well will drill though smaller pockets of hydrocarbons, which may cause a “blow-out" if the mud weight cannot balance the pressure. The same might happen when drilling into the main reservoir.

To prevent an uncontrolled blow-out, a subsurface safety valve is often installed. This valve has enough closing force to seal off the well and cut the drill string in an uncontrollable blow-out situation. However, unless casing is already also in place, hydrocarbons may also leave though other cracks inside the well and rise to the surface through porous or cracked rock. In addition to fire and pollution hazards, dissolved gas in seawater rising under a floating structure significantly reduces buoyancy.

The mud mix is a special brew designed to match the desired flow thickness, lubrication properties and specific gravity. Mud is a common name used for all kinds of fluids used in drilling completion and workover and can be oil-based, water-based or synthetic, and consists of powdered clays such as bentonite, oil, water and various additives and chemicals such as caustic soda, barite (sulfurous mineral), lignite (brown coal), polymers and emulsifiers

A special high-density mud called “kill fluid” is used to shut down a well for workover. Mud is recirculated. Coarse rock shales are separated in a shale shaker before it is passed though finer filters and recalibrated with new additives before returning to the mud holding tanks.

The well

Once the well has been drilled, it must be completed. Completing a well consists of a number of steps, such as installing the well casing, completion, installing the wellhead, and installing lifting equipment or treating the formation, if required.

Well casing

Installing the well casing is an important part of the drilling and completion process. Well casing consists of a series of metal tubes installed in the freshly drilled hole. Casing serves to strengthen the sides of the well hole, ensure that no oil or natural gas seeps out as it is brought to the surface, and keep other fluids or gases from seeping into the formation through the well. A good deal of planning is necessary to ensure that the right casing for each well is installed. Types of casing used depend on subsurface characteristics of the well, including the diameter of the well (which is dependent on the size of the drill bit used) and the pressures and temperatures experienced. In most wells, the diameter of the well hole decreases the deeper it is drilled, leading to a conical shape that must be taken into account when installing casing. The casing is normally cemented in place.

There are five different types of well casing. They include:

• Conductor casing, which is usually no more than 20 to 50 feet (7- 17 m) long, is installed before main drilling to prevent the top of the well from caving in and to help in the process of circulating the drilling fluid up from the bottom of the well.

• Surface casing is the next type of casing to be installed. It can be anywhere from 100 to 400 meters long and is smaller in diameter to fit inside the conductor casing. Its primary purpose is to protect fresh water deposits near the surface of the well from contamination by leaking hydrocarbons or salt water from deeper underground. It also serves as a conduit for drilling mud returning to the surface and helps protect the drill hole from damage during drilling.

• Intermediate casing is usually the longest section of casing found in a well. Its primary purpose is to minimize the hazards associated with subsurface formations that may affect the well. These include abnormal underground pressure zones, underground shales and formations that might otherwise contaminate the well, such as underground salt water deposits. Liner strings are sometimes used instead of intermediate casing. Liner strings are usually just attached to the previous casing with “hangers” instead of being cemented into place and are thus less permanent.

• Production casing, alternatively called the “oil string” or '”long string,” is installed last and is the deepest section of casing in a well. This is the casing that provides a conduit from the surface of the well to the petroleum-producing formation. The size of the production casing depends on a number of considerations, including the lifting equipment to be used, the number of completions required, and the possibility of deepening the well at a later date. For example, if it is expected that the well will be deepened later, then the production casing must be wide enough to allow the passage of a drill bit later on. It is also instrumental in preventing blow-outs, allowing the formation to be “sealed” from the top should dangerous pressure levels be reached.

Once the casing is installed, tubing is inserted inside the casing, from the opening well at the top to the formation at the bottom. The hydrocarbons that are extracted run up this tubing to the surface. The production casing is typically 5 to 28 cm (2 -11 in) with most production wells being 6 inches or more. Production depends on reservoir, bore, pressure, etc., and may be less than 100 barrels per day to several thousand barrels per day. (5,000 bpd is about 555 liters/minute). A packer is used between casing and tubing at the bottom of the well.

Completion

Well completion commonly refers to the process of finishing a well so that it is ready to produce oil or natural gas. In essence, completion consists of deciding on the characteristics of the intake portion of the well in the targeted hydrocarbon formation. There are a number of types of completions, including:

Ø Open hole completions are the most basic type and are only used in very competent formations that are unlikely to cave in. An open hole completion consists of simply running the casing directly down into the formation, leaving the end of the piping open without any other protective filter.

Ø Conventional perforated completions consist of production casing run through the formation. The sides of this casing are perforated, with tiny holes along the sides facing the formation, which allows hydrocarbons to flow into the well hole while still providing a suitable amount of support and protection for the well hole. In the past, “bullet perforators” were used. These were essentially small guns lowered into the well that sent off small bullets to penetrate the casing and cement. Today, “jet perforating” is preferred. This consists of small, electrically-fired charges that are lowered into the well. When ignited, these charges poke tiny holes through to the formation, in the same manner as bullet perforating.

Ø Sand exclusion completions are designed for production in an area that contains a large amount of loose sand. These completions are designed to allow for the flow of natural gas and oil into the well, while preventing sand from entering. The most common methods of keeping sand out of the well hole are screening or filtering systems. Both of these types of sand barriers can be used in open hole and perforated completions.

Ø Permanent completions are those in which the completion and wellhead are assembled and installed only once. Installing the casing, cementing, perforating and other completion work is done with small-diameter tools to ensure the permanent nature of the completion. Completing a well in this manner can lead to significant cost savings compared to other types.

Ø Multiple zone completion is the practice of completing a well such that hydrocarbons from two or more formations may be produced simultaneously, without mixing with each other. For example, a well may be drilled that passes through a number of formations on its way deeper underground, or it may be more desirable in a horizontal well to add multiple completions to drain the formation most effectively. When it is necessary to separate different completions, hard rubber “packing” instruments are used to maintain separation.

Ø Drainhole completions are a form of horizontal or slanted drilling. This type of completion consists of drilling out horizontally into the formation from a vertical well, essentially providing a drain for the hydrocarbons to run down into the well. These completions are more commonly associated with oil wells than with natural gas wells.