The Oil Well

Drilling

Cable tooling

Early oil wells were drilled with impact-type tools in a method called cable-tool drilling. A weighted chisel-shaped bit was suspended from a cable to a lever at the surface, where an up-and-down motion of the lever caused the bit to chip away the rock at the bottom of the hole. The drilling had to be halted periodically to allow loose rock chips and liquidsto be removed with a collecting device attached to the cable. At these times the chipping tip of the bit was sharpened, or “dressed” by the tool dresser. The borehole had to be free of liquids during the drilling so that the bit could remove rock effectively. This dry condition of the hole allowed oil and gas to flow to the surface when the bit penetrated a producing formation, thus creating the image of a “gusher” as a successful oil well. Often a large amount of oil was wasted before the well could be capped and brought under control (see also drilling machinery).

The rotary drill

During the mid- to late 20th century, rotary drilling became the preferred penetration method for oil and gas wells. In this method a special tool, the drill bit, rotates while bearing down on the bottom of the well, thus gouging and chipping its way downward. Probably the greatest advantage of rotary drilling over cable tooling is that the well bore is kept full of liquid during drilling. A weighted fluid (drilling mud) is circulated through the well bore to serve two important purposes. By its hydrostatic pressure, it prevents entry of the formation fluids into the well, thereby preventing blowouts and gushers (uncontrolled oil releases). In addition, the drilling mud carries the crushed rock to the surface, so that drilling is continuous until the bit wears out.

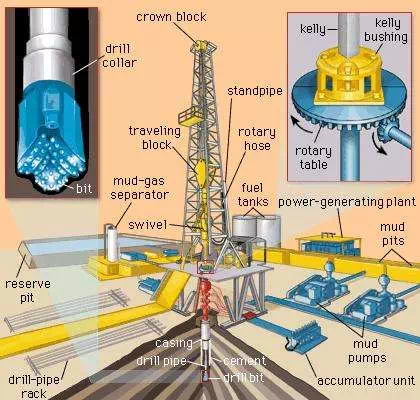

A land-based rotary drilling rig.Adapted from Petroleum Extension Service (PETEX), The University of Texas at Austin

Rotary drilling techniques have enabled wells to be drilled to depths of more than 9,000 metres (30,000 feet). Formations having fluid pressures greater than 1,400 kg per square cm (20,000 pounds per square inch) and temperatures greater than 250 °C (480 °F) have been successfully penetrated. Additionally, improvements to rotary drilling techniques have reduced the time it takes to drill long distances. A powered rotary steerable system (RSS) that can be controlled and monitored remotely has become the preferred drilling technology for extended-reach drilling (ERD) and deepwater projects. In some cases, onshore well projects that would have taken 35 days to drill in 2007 could be finished in only 20 days 10 years later by using the RSS. Offshore, one of the world’s deepest wells in the Chayvo oil field, off the northeastern corner of Sakhalin Island in Russia, was drilled by Exxon Neftegas Ltd. using its “fast drilling” process. The Z-44 well, drilled in 2012, is 12,345 metres (about 40,500 feet) deep.

A common tricone oil-drill bit with three steel cones rotating on bearings.Reed Saxon/AP

The drill pipe

The drill bit is connected to the surface equipment through the drill pipe, a heavy-walled tube through which the drilling mud is fed to the bottom of the borehole. In most cases, the drill pipe also transmits the rotary motion to the bit from a turntable at the surface. The top piece of the drill pipe is a tube of square (or occasionally six- or eight-sided) cross section called the kelly. The kelly passes through a similarly shaped hole in the turntable. At the bottom end of the drill pipe are extra-heavy sections called drill collars, which serve to concentrate the weight on the rotating bit. In order to help maintain a vertical well bore, the drill pipe above the collars is usually kept in tension. The drilling mud leaves the drill pipe through the bit in such a way that it scours the loose rock from the bottom and carries it to the surface. Drilling mud is carefully formulated to assure the correct weight and viscosity properties for the required tasks. After screening to remove the rock chips, the mud is held in open pits or metal tanks to be recirculated through the well. The mud is picked up by piston pumps and forced through a swivel joint at the top of the kelly.

Three oil-rig roughnecks pulling drill pipe out of an oil well.John Boykin—Stock Connection Distribution/Alamy

The derrick

The hoisting equipment that is used to raise and lower the drill pipe, along with the machinery for rotating the pipe, is contained in the tall derrick that is characteristic of rotary drilling rigs. While early derricks were constructed at the drilling site, modern rigs can be moved from one site to the next. The drill bit wears out quickly and requires frequent replacement, often once a day. This makes it necessary to pull the entire drill string (the column of drill pipe) from the well and stand all the joints of the drill pipe vertically at one side of the derrick. Joints are usually 9 metres (29.5 feet) long. While the bit is being changed, sections of two or three joints are separated and stacked. Drilling mud is left in the hole during this time to prevent excessive flow of fluids into the well.

Workers on an oil rig, Oklahoma City.© Index Open

Casing

Modern wells are not drilled to their total depth in a continuous process. Drilling may be stopped for logging and testing (see below Formation evaluation), and it may also be stopped to run (insert) casing and cement it to the outer circumference of the borehole. (Casing is steelpipe that is intended to prevent any transfer of fluids between the borehole and the surrounding formations.) Since the drill bit must pass through any installed casing in order to continue drilling, the borehole below each string of casing is smaller than the borehole above. In very deep wells, as many as five intermediate strings of progressively smaller-diameter casing may be used during the drilling process.

The turbodrill

One variation in rotary drilling employs a fluid-powered turbine at the bottom of the borehole to produce the rotary motion of the bit. Known as the turbodrill, this instrument is about nine metres long and is made up of four major parts: the upper bearing, the turbine, the lower bearing, and the drill bit. The upper bearing is attached to the drill pipe, which either does not rotate or rotates at a slow rate (6 to 8 revolutions per minute). The drill bit, meanwhile, rotates at a much faster rate (500 to 1,000 revolutions per minute) than in conventional rotary drilling. The power source for the turbodrill is the mud pump, which forces mud through the drill pipe to the turbine. The mud is diverted onto the rotors of the turbine, turning the lower bearing and the drill bit. The mud then passes through the drill bit to scour the hole and carry chips to the surface.

The turbodrill is capable of very fast drilling in harsh environments, including high-temperature and high-pressure rock formations. Periodic technological improvements have included longer-wearing bits and bearings. Turbodrills were originally developed and widely used in Russia and Central Asia. Given their capabilities for extended reach and drilling in difficult rock formations, turbodrill applications expanded into formerly inaccessible regions on land and offshore. Turbodrills with diamond-impregnated drill bits became the choice for hard, abrasive rock formations. The high rotating speeds exceeded more than 1,000 revolutions per minute, which facilitated faster rates of penetration (ROPs) during drilling operations.

Directional drilling

Frequently, a drilling platform and derrick cannot be located directly above the spot where a well should penetrate the formation (if, for example, a petroleum reservoir lies under a lake, town, or harbour). In such cases, the surface equipment must be offset and the well bore drilled at an angle that will intersect the underground formation at the desired place. This is done by drilling the well vertically to start and then angling it at a depth that depends on the relative position of the target. Since the nearly inflexible drill pipe must be able to move and rotate through the entire depth, the angle of the borehole can be changed only a few degrees per tens of feet at any one time. In order to achieve a large deviation angle, therefore, a number of small deviations must be made. The borehole, in effect, ends up making a large arc to reach its objective. The original tool for “kicking off” such a well was a mechanical device called the whipstock. This consisted of an inclined plane on the bottom of the drill pipe that was oriented in the direction the well was intended to take. The drill bit was thereby forced to move off in the proper direction. A more recent technique makes use of steerable motor assemblies containing positive-displacement motors (PDMs) with adjustable bent-housing mud motors. The bent housing misaligns the bit face away from the line of the drill string, which causes the bit to change the direction of the hole being drilled. PDM bent-housing motor assemblies are most commonly used to “sidetrack” out of existing casing. (Sidetracking is drilling horizontal lateral lines out from existing well bores [drill holes].) In mature fields where engineers and drilling staff target smaller deposits of oil that were bypassed previously, it is not uncommon to use existing well bores to develop the bypassed zones. In order to accomplish this, a drill string is prepared to isolate the other producing zones. Later, a casing whipstock is used to mill (or grind) through the existing casing. The PDM bent-housing motor assembly is then run into the cased well to divert the trajectory of the drill so that the apparatus can point toward the targeted deposit.

As more-demanding formations are encountered—such as in ultradeep, high-pressure, high-temperature, abrasive rock and shales—wear and tear on the mud motors and bits causes frequent “trips.” (Trips involve pulling worn-out mechanical bits and motors from the well, attaching replacements, and reentering the well to continue drilling.) To answer these challenges, modern technologies incorporate an RSS capable of drilling vertical, curved, and horizontal sections in one trip. During rotary steering drilling, a surface monitoring system sends steering control commands to the downhole steering tools in a closed-loop control system. In essence, two-way communication between the surface and the downhole portions of the equipment improves the drilling rate of penetration (ROP). The surface command transmits changes in the drilling fluid pressure and flow rate in the drilling pipe. Pulse signals of drilling fluid pressure with different pulse widths are generated by adjusting the timing of the pulse valve, which releases the drilling fluid into the pipe.

Further advances to the RSS include electronically wired drill pipe that is intended to speed communication from the surface to the bit. This technology has matured to the point where it coordinates with logging-while-drilling (LWD) systems. It also provides faster data transfer than pulsed signaling techniques and continuous data in real time from the bottom hole assembly. The safety advantages, however, perhaps trump the increases in the rate of information transfer. Knowing the downhole temperature and pressure data in real time can give the operator advance notice of changing formation conditions, which allows the operator more control over the well.

Smart field technologies, such as directional drilling techniques, have rejuvenated older fields by accessing deposits that were bypassed in the past in favour of more easily extractable plays. Directional drilling techniques have advanced to the point where well bores can end in horizontal sections extending into previously inaccessible areas of a reservoir. Also, multiple deposits can be accessed through extended-reach drilling by a number of boreholes fanning out from a single surface structure or from various points along a vertical borehole. Technology has allowed once noncommercial resources, such as those found in harsh or relatively inaccessible geologic formations, to become developable reserves.

Offshore platforms

Shallow water

Many petroleum reservoirs are found in places where normal land-based drilling rigs cannot be used. In inland waters or wetland areas, a drilling platform and other drilling equipment may be mounted on a barge, which can be floated into position and then made to rest on the seafloor. The actual drilling platform can be raised above the water on masts if necessary. Drilling and other operations on the well make use of an opening through the barge hull. This type of rig is generally restricted to water depths of 15 metres (50 feet) or less.

Oil derricks in the Caspian Sea near Baku, Azerbaijan.Dieter Blum/Peter Arnold, Inc.

In shallow Arctic waters where drifting ice is a hazard for fixed platforms, artificial islands have been constructed of rock or gravel. Onshore in Arctic areas, permafrost makes drilling difficult because melting around and under the drill site makes the ground unstable. There too, artificial islands are built up with rock or gravel.

Away from the nearshore zone, shallow offshore drilling takes place in less than 152 metres (500 feet) of water, which permits the use of fixed platforms with concrete or metal legs planted into the seafloor. Control equipment resides at the surface, on the platform with the wellhead positioned on the seafloor. When the water depth is less than 457 metres (1,500 feet), divers can easily reach the wellhead to perform routine maintenance as required, which makes shallow offshore drilling one of the safest methods of offshore production.

Deep and ultradeep water

In deeper, more open waters up to 5,000 feet (1,524 metres) deep over continental shelves, drilling is done from free-floating platforms or from platforms made to rest on the bottom. Floating rigs are most often used for exploratory drilling and drilling in waters deeper than 3,000 feet (914 metres), while bottom-resting platforms are usually associated with the drilling of wells in an established field or in waters shallower than 3,000 feet. One type of floating rig is the drill ship, which is used almost exclusively for exploration drilling before commitments to offshore drilling and production are made. This is an oceangoing vessel with a derrick mounted in the middle, over an opening for the drilling operation. Such ships were originally held in position by six or more anchors, although some vessels were capable of precise maneuvering with directional thrust propellers. Even so, these drill ships roll and pitch from wave action, making the drilling difficult. At present, dynamicpositioning gear systems are affixed to drill ships, which permit operations in heavy seas or other severe conditions.

·

·

The Jack Ryan, a drill ship capable of exploring for oil in water 3,000 metres (10,000 feet) deep.© BP p.l.c.

jack-up oil platformA jack-up rig drilling for oil in the Caspian Sea

Floating deepwater drilling and petroleum production methods vary, but they all involve the use of fixed (anchored) systems, which may be put in place once drilling is complete and the drilling rig demobilized. Additional production is established by a direct connection with the production platform or by connecting risers between the subsea wellheads and the production platform. The Seastar floating system operates in waters up to 3,500 feet (1,067 metres) deep. It is essentially a small-scale tension-leg platform system that allows for side-to-side movement but minimizes up-and-down movement. Given the vertical tension, production is tied back to “dry” wellheads (on the surface) or to “trees” (structures made up of valves and flow controls) on the platform that are similar to those of the fixed systems.

Semisubmersible deepwater production platforms are more stable. Their buoyancy is provided by a hull that is entirely underwater, while the operational platform is held well above the surface on supports. Normal wave action affects such platforms very little. These platforms are commonly kept in place during drilling by cables fastened to the seafloor. In some cases the platform is pulled down on the cables so that its buoyancy creates a tension that holds it firmly in place. Semisubmersible platforms can operate in ultradeep water—that is, in waters more than 3,050 metres (10,000 feet) deep. They are capable of drilling to depths of more than 12,200 metres (approximately 40,000 feet).

Drilling platforms capable of ultradeepwater production—that is, beyond 1,830–2,130 metres (approximately 6,000–7,000 feet) deep—include tension-leg systems and floating production systems (FPS), which can move up and down in response to ocean conditions as semisubmersibles perform. The option to produce from wet (submerged) or dry trees is considered with respect to existing infrastructure, such as regional subsea pipelines. Without such infrastructure, wet trees are used and petroleum is exported to a nearby FPS. A more versatile ultradeepwater system is the spar type, which can perform in waters nearly 3,700 metres (approximately 12,000 feet) deep. Spar systems are moored to the seabed and designed in three configurations: (1) a conventional one-piece cylindrical hull, (2) a truss spar configuration, where the midsection is composed of truss elements connecting an upper, buoyant hull (called a hard tank) with a bottom element (soft tank) containing permanent ballast, and (3) a cell spar, which is built from multiple vertical cylinders. In the cell spar configuration, none of the cylinders reach the seabed, but all are tethered to the seabed by mooring lines.

Fixed platforms, which rest on the seafloor, are very stable, although they cannot be used to drill in waters as deep as those in which floating platforms can be used. The most popular type of fixed platform is called a jack-up rig. This is a floating (but not self-propelled) platform with legs that can be lifted high off the seafloor while the platform is towed to the drilling site. There the legs are cranked downward by a rack-and-pinion gearing system until they encounter the seafloor and actually raise the platform 10 to 20 metres (33 to 66 feet) above the surface. The bottoms of the legs are usually fastened to the seafloor with pilings. Other types of bottom-setting platforms, such as the compliant tower, may rest on flexible steel or concrete bases that are constructed onshore to the correct height. After such a platform is towed to the drilling site, flotation tanks built into the base are flooded, and the base sinks to the ocean floor. Storage tanks for produced oil may be built into the underwater base section.

Three types of offshore drilling platforms.From R. Baker, A Primer of Offshore Operations, 2nd ed., Petroleum Extension Service (PETEX), © 1985 by The University of Texas at Austin, all rights reserved

For both fixed rigs and floating rigs, the drill pipe must transmit both rotary power and drilling mud to the bit; in addition, the mud must be returned to the platform for recirculation. In order to accomplish these functions through seawater, an outer casing, called a riser, must extend from the seafloor to the platform. Also, a guidance system (usually consisting of cables fastened to the seafloor) must be in place to allow equipment and tools from the surface to enter the well bore. In the case of a floating platform, there will always be some motion of the platform relative to the seafloor, so this equipment must be both flexible and extensible. A guidance system will be especially necessary if the well is to be put into production after the drilling platform is moved away.

The Thunder Horse, a semisubmersible oil production platform, constructed to operate several wells in waters more than 1,500 metres (5,000 feet) deep in the Gulf of Mexico.

Using divers to maintain subsea systems is not as feasible in deep waters as in shallow waters. Instead, an intricate system of options has been developed to distribute risks away from any one subsea source, such as a wet tree. Smart well control and connection systems assist from the seafloor in directing subsea manifolds, pipelines, risers, and umbilicals prior to oil being lifted to the surface. Subsea manifolds direct the subsea systems by connecting wells to export pipelines and risers and onward to receiving tankers, pipelines, or other facilities. They direct produced oil to flowlines coincidental to distributing injected water, gas, or chemicals.

The reliance on divers in subsea operations began to fade in the 1970s, when the first unmanned vehicles or remotely operated vehicles (ROVs) were adapted from space technologies. ROVs became essential in the development of deepwater reserves. Robotics technology, which was developed primarily for the ROV industry, has been adapted for a wide range of subsea applications.

Formation evaluation

Advances in technology have occurred in well logging and the evaluation of geological formations more than in any other area of petroleum production. Historically, after a borehole penetrated a potential productive zone, the formations were tested to determine their nature and the degree to which completion procedures (the series of steps that convert a drilling well into a producing well) should be conducted. The first evaluation was usually made using well logging methods. The logging tool was lowered into the well by a steel cable and was pulled past the formations while response signals were relayed to the surface for observation and recording. Often these tools made use of the differences in electrical conductivities of rock, water, and petroleum to detect possible oil or gas accumulations. Other logging tools used differences in radioactivity, neutron absorption, and acoustic wave absorption. Well log analysts could use the recorded signals to determine potential producing formations and their exact depth. Only a production, or “formation,” test, however, could establish the potential productivity.

The production test that was historically employed was the drill stem test, in which a testing tool was attached to the bottom of the drill pipe and was lowered to a point opposite the formation to be tested. The tool was equipped with expandable seals for isolating the formation from the rest of the borehole, and the drill pipe was emptied of mud so that formation fluid could enter. When enough time had passed, the openings into the tool were closed and the drill pipe was brought to the surface so that its contents could be measured. The amounts of oil and gas that flowed into the drill pipe during the test and the recorded pressures were used to judge the production potential of the formation.

With advances in measurement-while-drilling (MWD) technologies, independent well logging and geological formation evaluation runs became more efficient and more accurate. Other improvements in what has become known as smart field technologies included a widening range of tool sizes and deployment options that enable drilling, logging, and formation evaluation into smaller boreholes simultaneously. Formation measurement techniques that employ logging-while-drilling (LWD) equipment include gamma ray logging, resistivity measurement, density and neutron porosity logging, sonic logging, pressure testing, fluid sampling, and borehole diameter measurements using calipers. LWD applications include flexible logging systems for horizontal wells in shale plays with curvatures as sharp as 68° per 100 feet. Another example of an improvement in smart field technologies is use of rotary steerable systems in deep waters, where advanced LWD is vastly reducing the evaluation time of geological formations, especially in deciding whether to complete or abandon a well. Reduced decision times have led to an increase in the safety of drilling, and completion operations have become much improved, as the open hole is cased or plugged and abandoned that much sooner. With traditional wireline logs, reports of findings may not be available for days or weeks. In comparison, LWD coupled with RSS is controlled by the drill’s ROP. The formation evaluation sample rate combined with the ROP determine the eventual number of measurements per drilled foot that will be recorded on the log. The faster the ROP, the faster the sample rate and its recording onto the well log sent to the surface operator for analysis and decision making.

Well completion

Production tubing

If preliminary tests show that one or more of the formations penetrated by a borehole will be commercially productive, the well must be prepared for the continuous production of oil or gas. First, the casing is completed to the bottom of the well. Cement is then forced into the annulus between the casing and the borehole wall to prevent fluid movement between formations. As mentioned earlier, this casing may be made up of progressively smaller-diameter tubing, so that the casing diameter at the bottom of the well may range from 10 to 30 cm (4 to 12 inches). After the casing is in place, a string of production tubing 5 to 10 cm (2 to 4 inches) in diameter is extended from the surface to the productive formation. Expandable packing devices are placed on the tubing to seal the annulus that lies between the casing and the production tubing within the producing formation from the annulus that lies within the remainder of the well. If a lifting device is needed to bring the oil to the surface, it is generally placed at the bottom of the production tubing. If several producing formations are penetrated by a single well, as many as four production strings may be hung. However, as deeper formations are targeted, conventional completion practices often produce diminishing returns.

Perforating and fracturing

Since the casing is sealed with cement against the productive formation, openings must be made in the casing wall and cement to allow formation fluid to enter the well. A perforator tool is lowered through the tubing on a wire line. When it is in the correct position, bullets are fired or explosive charges are set off to create an open path between the formation and the production string. If the formation is quite productive, these perforations (usually about 30 cm, or 12 inches, apart) will be sufficient to create a flow of fluid into the well. If not, an inert fluid may be injected into the formation at pressure high enough to cause fracturing of the rock around the well and thus open more flow passages for the petroleum.

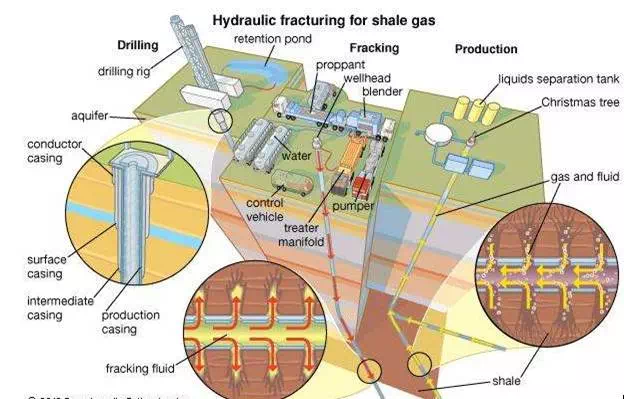

Three steps in the extraction of shale gas: drilling a borehole into the shale formation and lining it with pipe casing; fracking, or fracturing, the shale by injecting fluid under pressure; and producing gas that flows up the borehole, frequently accompanied by liquids.

Tight oil formations are typical candidates for hydraulic fracturing(fracking), given their characteristically low permeability and low porosity. During fracturing, water, which may be accompanied by sand, and less than 1 percent household chemicals, which serve as additives, are pumped into the reservoir at high pressure and at a high rate, causing a fracture to open. Sand, which served as the propping agent (or “proppant”), is mixed with the fracturing fluids to keep the fracture open. When the induced pressure is released, the water flows back from the well with the proppant remaining to prop up the reservoir rock spaces. The hydraulic fracturing process creates network of interconnected fissures in the formation, which makes the formation more permeable for oil, so that it can be accessed from beyond the near-well bore area.

In early wells, nitroglycerin was exploded in the uncased well bore for the same purpose. An acid that can dissolve portions of the rock is sometimes used in a similar manner.

Surface valves

When the subsurface equipment is in place, a network of valves, referred to as a Christmas tree, is installed at the top of the well. The valves regulate flow from the well and allow tools for subsurface work to be lowered through the tubing on a wire line. Christmas trees may be very simple, as in those found on low-pressure wells that must be pumped, or they may be very complex, as on high-pressure flowing wells with multiple producing strings.

A worker operating a “Christmas tree,” a structure of valves for regulating flow at the surface of an oil well.Ron Scott/Alamy