hydrocarbon gas liquids

Natural gas and crude oil are mixtures of different hydrocarbons. Hydrocarbons are molecules of carbon and hydrogen in various combinations. Hydrocarbon gas liquids (HGL) are hydrocarbons that occur as gases at atmospheric pressure and as liquids under higher pressures. HGL can also be liquefied by cooling. The specific pressures and temperatures at which the gases liquefy vary by the type of HGL. HGL may be described as being light or heavy according to the number of carbon atoms and hydrogen atoms in an HGL molecule.

HGL are categorized chemically as:

· Alkanes, or paraffins

o Ethane—C2H6

o Propane—C3H8

o Butanes: normal butane and isobutane—C4H10

o Natural gasoline or pentanes plus—C5H12 and heavier

· Alkenes, or olefins

o Ethylene—C2H4

o Propylene—C3H6

o Butylene and isobutylene—C4H8

Hydrocarbon gas liquids are from natural gas and crude oil

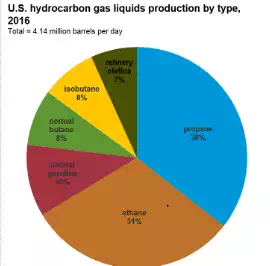

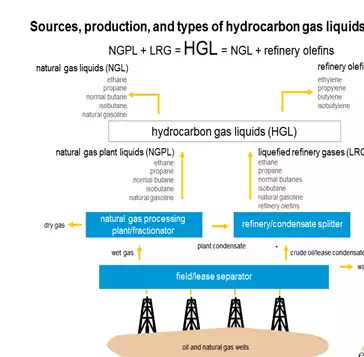

HGL are found in raw natural gas and crude oil, and they are extracted when natural gas is processed at natural gas processing plants and when crude oil is refined into petroleum products. Natural gas plant liquids (NGPL), which account for most of HGL production in the United States, fall solely into the alkanes category. Refinery production accounts for the remainder of U.S. alkanes production, and it accounts for all of the olefins production data that are published by the U.S. Energy Information Administration (EIA). Greater volumes of olefins are produced at petrochemical plants from HGL and heavier feedstock. EIA does not collect or report petrochemical production data.

Hydrocarbon gas liquids have many uses

Because HGL straddle the gas/liquid boundary, their versatility and high energy density in liquid form make them useful for many purposes:

· Feedstock in petrochemical plants to make chemicals, plastics, and synthetic rubber

· Fuels for heating, cooking, and drying

· Fuels for transportation

· Additives for motor gasoline production

· Diluent (a diluting or thinning agent) for transportation of heavy crude oil

In 2016, total HGL use accounted for about 13% of total U.S. petroleum consumption.

|

|

Where do Hydrocarbon Gas Liquids Come From?

Hydrocarbon gas liquids are derived from natural gas and crude oil

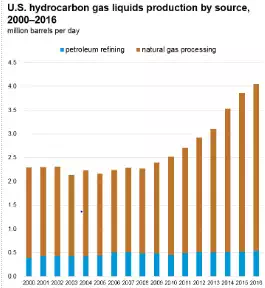

Hydrocarbon gas liquids (HGL) are produced when raw natural gas is processed at natural gas processing plants and when crude oil is refined into petroleum products. Most of the HGL produced in the United States are separated from natural gas at natural gas processing plants.

Hydrocarbon gas liquids from natural gas processing

HGL are present as gases in deposits of natural gas. Raw, or untreated, natural gas produced from natural gas wells and oil wells is called wet gas because it sometimes contains HGL, along with water vapor and other nonhydrocarbon gases. HGL should not be confused with lease condensate separated out of associated and nonassociatednatural gas at lease facilities. The liquid condensate is usually added to crude oil in pipelines that transport oil to refineries.

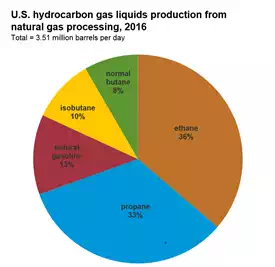

Natural gas is usually treated at natural gas processing plants before it enters natural gas transmission pipelines. HGL extracted from natural gas as liquids at these plants are called natural gas plant liquids(NGPL). Natural gas that has been processed to remove most of the HGL and nonhydrocarbon compounds is called dry gas, which consists of mostly methane. Natural gas pipeline operators have strict specifications for the characteristics (such as the heat content) of the dry natural gas that they accept, which in turn limits the amount of HGL contained in natural gas that is transported through these pipelines. Mixed HGL streams (also known as Y-grade) are separated from each other by the process of fractionation. Fractionation facilities may be co-located at natural gas processing plants, or they may receive mixed HGL streams from several processing plants. Fractionation facilities separate some or all the individual HGL that are then sold as purity products—ethane, propane, normal butane, and isobutane product streams consisting of a minimum of 90% of one type of HGL molecule.Most of the natural gas processing and fractionation plants in the United States are located in areas where natural gas and crude oil production is concentrated. In 2016, HGL from natural gas processing accounted for about 87% of total U.S. HGL production.

Hydrocarbon gas liquids from crude oil refining

Propane and propylene are the HGL streams that are produced and sold as separate purity products in the largest volumes by petroleum refiners. Most of the other volumes of HGL produced at refineries are burned as fuels or are used to make gasoline and petrochemical feedstock.

Transporting and Storing Hydrocarbon Gas Liquid:

Hydrocarbon gas liquids are transported by various means

Hydrocarbon gas liquids (HGL) that are extracted from natural gas or that are produced at petroleum refineries may be transported as liquids in mixtures of HGL or as separate HGL purity products in pipelines, rail cars, trucks, ships, and barges.

HGL are transported in five main forms:

· Y-grade (raw, unseparated HGL)

· E-P mix (most frequently 80% ethane and 20% propane)

· P/P mix (refinery-grade propane-propylene mixture)

· LPG (mixture of liquefied propane, normal butane, and isobutane)

· Purity products (separate, distinct products; mostly ethane, propane, and normal butane)

Pipelines carry hydrocarbon gas liquids from where they are produced to where they are stored

Most of the HGL produced in the United States are transported in pipelines from where they are produced to places where they are used or to places where they are stored for distribution.

Most of HGL transported by pipeline is Y-grade quality and is transported to fractionation plants. E-P mix is mostly transported in pipelines from fractionation plants to ethylene crackers, where it is used to produce ethylene and other olefins. On the Gulf Coast, P/P mix is often transported by dedicated pipelines to propylene splitters that separate refinery-grade (lower grade or quality) propylene into higher quality, polymer-grade or chemical-grade propylene, which is then sold to petrochemical plants. Propane and normal butane are transported in liquefied petroleum gas (LPG)1 pipelines or in batches as purity products in pipelines that transport other kinds of petroleum products.

Railroads and trucks transport HGL to consumers

Many regions in the United States (like the West, New England, and Florida) are not served by HGL pipelines. In these areas, railroads often transport large volumes of HGL to wholesale and bulk purchasers in pressurized railroad tankcars. Railroads and trucks are also used to transport HGL to consumers. The primary HGL product delivered to consumers is consumer-grade propane, which is transported by truck in pressurized tanks to homes, farms, and businesses where it can be used as engine fuel, for crop drying, for space heating and water heating, and for cooking, among other applications.

Special ships are used to transport HGL to and from the United States

Special ships are used to transport HGL (usually LPG1) to and from shipping ports in the United States. The ships, called gas tankers, vary in size and vary by the method used to keep the HGL in liquid form. The HGL may be pressurized, refrigerated, or both. Over short distances, propane and normal butane are also moved by barge along intercoastal waterways and navigable rivers.

HGL are stored in a variety of ways

Storage of HGL is necessary because HGL may be produced in volumes that exceed the capacity of the different modes of transportation used to carry the HGL to consumers. Production may also not match HGL seasonal requirements. For example, production of propane is relatively consistent throughout the year, but demand for propane is usually lower in the summer and higher in the fall and winter. Propane is stored when demand is low, and propane is withdrawn from storage when demand is high.

Large volumes of HGL are primarily stored as a pressurized liquid in underground caverns. Most of the caverns are in salt formations, but some propane storage caverns are mined out of shale, granite, and limestone rock. In regions where geology is not well suited for underground caverns, large aboveground tanks may be used. Aboveground tanks are the primary storage method for propane and butanes in New England. Once HGL are transported close to consumers, they are stored in pressurized (and sometimes cooled) tanks located above or below ground. LPG, which can refer to propane, butanes, or a mixture of the two, is stored and distributed in many different sizes of tanks, from the small canisters used for torches and camping stoves, to 90,000-gallon bullet-shaped tanks used at industrial facilities.

Uses of Hydrocarbon Gas Liquids:

Hydrocarbon gas liquids have many uses

Hydrocarbon gas liquids (HGL) are versatile products used in every end-use sector—residential, commercial, industrial (manufacturing and agriculture), transportation, and electric power. The chemical compositions of HGL purity products (HGL streams with at a minimum of 90% of one type of HGL) are similar, but their uses vary.

Hydrocarbon gas liquids, uses, products, and consumers

|

HGL |

Uses |

End-use products |

End-use sectors |

|

Ethane |

Petrochemical feedstock for ethylene production; power generation |

Plastics; anti-freeze; detergents |

Industrial |

|

Propane |

Fuel for space heating, water heating, cooking, drying, and transportation; petrochemical feedstock |

Fuel for heating, cooking, and drying; plastics |

Industrial (includes manufacturing and agriculture), residential, commercial, and transportation |

|

Butanes: normal butane and isobutene |

Petrochemical and petroleum refinery feedstock; motor gasoline blending |

Motor gasoline; plastics; synthetic rubber; lighter fuel |

Industrial and transportation |

|

Natural gasoline (pentanes plus) |

Petrochemical feedstock; additive to motor gasoline; diluent for heavy crude oil |

Motor gasoline; ethanol denaturant; solvents |

Industrial and transportation |

|

Refinery olefins (ethylene, propylene, normal butylene, and isobutylene) |

Intermediate feedstocks in the petrochemical industry |

Plastics; artificial rubber; paints and solvents; resins |

Industrial |

Propane is used as a fuel and is used to make chemicals

Most of the propane consumed in the United States is used as a fuel, generally in areas where the supply of natural gas is limited or not available. This use is highly seasonal, with the largest consumption occurring in the fall and winter months. Propane sold as a fuel for the consumer market is generally defined as HD-5, which contains a minimum of 90% propane by volume, with small quantities of other hydrocarbon gases. HD-10, which contains up to 10% propylene, is the accepted standard for propane in California.

Propane has two general market categories: consumer (primarily as fuel) and nonconsumer (primarily for nonfuel or feedstock uses). Propane has four major consumer uses:

· In homes, for space heating and water heating; for cooking; for drying clothes; and for fueling gas fireplaces, barbecue grills, and backup electrical generators

· On farms, for heating livestock housing and greenhouses, for drying crops, for pest and weed control, and for powering farm equipment and irrigation pumps

· In businesses and industry, to power fork lifts, electric welders, and other equipment

· As a fuel for on-road internal combustion engine vehicles such as cars, school buses, or delivery vans and non-road vehicles such as tractors and lawn mowers

The nonconsumer market for propane is the petrochemical industry. The primary use of propane in the petrochemical industry is as a feedstock, along with ethane and naphtha, in petrochemical crackers to produce ethylene, propylene, and other olefins. Propane can also be used as a dedicated feedstock in the petrochemical industry for on-purpose propylene production. Propylene and the other olefins may be converted into a variety of products, mostly plastics and resins, and also glues, solvents, and coatings.

Ethane is mainly used to produce ethylene, a feedstock to make plastics

Ethane is mainly used to produce ethylene, which is then used by the petrochemical industry to produce a range of intermediate products, most of which are converted into plastics. Ethane consumption in the United States has increased over the past several years because of its increased supply and lower cost relative to other petrochemical feedstocks such as propane and naphtha. Ethane can also be used directly as a fuel for power generation, either on its own or blended with natural gas. Because demand for ethane is almost entirely in the petrochemical sector, and because this product is difficult to transport by any mode other than in dedicated pipelines, supply and demand for ethane must be closely matched. The increase in the supply of ethane starting in 2008, along with other natural gas plant liquids (NGPL), has resulted in some natural gas processors choosing not to recover the ethane that is produced with raw natural gas. Instead, this ethane is left in the natural gas that enters the interstate natural gas pipeline system. This process is referred to as ethane rejection, because the producer rejects the ethane stream into the dry natural gas instead of recovering it along with other HGL.

The presence of ethane in dry natural gas boosts its heat value—calculated in British thermal units (Btu) per standard cubic foot of gas (Btu/scf)—above the heat value of methane (CH4), which is approximately 1,010 Btu/scf. Most of the additional heat content of pipeline-delivered natural gas higher than the 1,010 Btu/scf level can generally be attributed to the ethane contained in the natural gas transported in pipelines. The U.S. Energy Information Administration publishes the heat content of natural gas delivered to consumers in each state. Not only does the petrochemical industry consume ethane, but so does every natural gas consumer in the United States to some degree.

Butanes: normal butane and isobutane are mostly used as blending stocks for gasoline

Although some normal butane is used as a fuel for lighters, most of it is blended into gasoline, especially during the cooler months. Because demand for isobutane exceeds supply, normal butane is also converted into isobutane through isomerization. Normal butane can also be used as a feedstock in the petrochemical industry. When normal butane is used in petrochemical cracking, the process yields (among other chemicals) butadiene, which is a precursor to synthetic rubber. Isobutane, whether from natural gas plants, refineries, or isomerized from normal butane, is used to produce alkylates, which increase octane in gasoline and control the volatility of gasoline. High-purity isobutane can also be used as a refrigerant.

Natural gasoline is used in fuels and in oil transportation

Natural gasoline (also known as pentanes plus) can be blended into the fuels used in internal combustion engines, particularly motor gasoline. In the United States, natural gasoline is added to fuel ethanol as a denaturant to make the ethanol undrinkable (this is required by law). Some ethanol producers use natural gasoline to make E85.