crude oil

What is crude oil and what are petroleum products?

Crude oil is a mixture of hydrocarbons that formed from plants and animals that lived millions of years ago. Crude oil is a fossil fuel, and it exists in liquid form in underground pools or reservoirs, in tiny spaces within sedimentary rocks, and near the surface in tar (or oil) sands. Petroleum products are fuels made from crude oil and other hydrocarbons contained in natural gas. Petroleum products can also be made from coal, natural gas, and biomass.

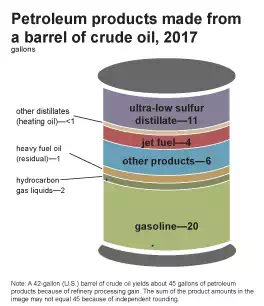

Products made from crude oil

After crude oil is removed from the ground, it is sent to a refinery where different parts of the crude oil are separated into useable petroleum products. These petroleum products include gasoline, distillates such as diesel fuel and heating oil, jet fuel, petrochemical feedstocks, waxes, lubricating oils, and asphalt. A U.S 42-gallon barrel of crude oil yields about 45 gallons of petroleum products in U.S. refineries because of refinery processing gain. This increase in volume is similar to what happens to popcorn when it is popped.

Refining Crude Oil

How crude oil is refined into petroleum products

Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks

for making chemicals.

Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. Petroleum refineries are complex and expensive industrial facilities. All refineries have three basic steps:

· Separation

· Conversion

· Treatment

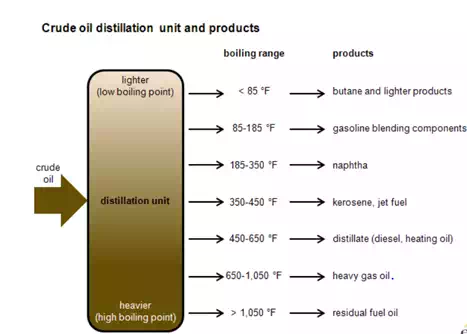

Separation

Modern separation involves piping crude oil through hot furnaces. The resulting liquids and vapors are discharged into distillation units. All refineries have atmospheric distillation units, while more complex refineries may have vacuum distillation units.

Fluid catalytic cracking distillation unit

Source: Chevron (copyrighted).

Refining workers overlooking a refinery

Inside the distillation units, the liquids and vapors separate into petroleum components called fractions according to their boiling points. Heavy fractions are on the bottom and light fractions are on the top. The lightest fractions, including gasoline and liquefied refinery gases, vaporize and rise to the top of the distillation tower, where they condense back to liquids. Medium weight liquids, including kerosene and distillates, stay in the middle of the distillation tower. Heavier liquids, called gas oils, separate lower down in the distillation tower, while the heaviest fractions with the highest boiling points settle at the bottom of the tower.

Conversion

After distillation, heavy, lower-value distillation fractions can be processed further into lighter, higher-value products such as gasoline. This is where fractions from the distillation units are transformed into streams (intermediate components) that eventually become finished products. The most widely used conversion method is called cracking because it uses heat, pressure, catalysts, and sometimes hydrogen to crack heavy hydrocarbon molecules into lighter ones. A cracking unit consists of one or more tall, thick-walled, rocket-shaped reactors and a network of furnaces, heat exchangers, and other vessels. Complex refineries may have one or more types of crackers, including fluid catalytic cracking units and hydrocracking/hydrocracker units.

Cracking is not the only form of crude oil conversion. Other refinery processes rearrange molecules to add value rather than splitting molecules. Alkylation, for example, makes gasoline components by combining some of the gaseous byproducts of cracking. The process, which essentially is cracking in reverse, takes place in a series of large, horizontal vessels and tall, skinny towers. Reforming uses heat, moderate pressure, and catalysts to turn naphtha, a light, relatively low-value fraction, into high-octane gasoline components.

Treatment

The finishing touches occur during the final treatment. To make gasoline, refinery technicians carefully combine a variety of streams from the processing units. Octane level, vapor pressure ratings, and other special considerations determine the gasoline blend.

Storage

Both incoming crude oil and the outgoing final products are stored temporarily in large tanks on a tank farm near the refinery. Pipelines, trains, and trucks carry the final products from the storage tanks to other locations across the country.