Slurry

Slurry reactors are three phase reactors (solid/liquid/gas). Pictured below is a slurry reactor used in the production of polyethylene products.

General Information

Slurry reactors are three-phase reactors, meaning they can be used to react solids, liquids, and gases simultaneously. They usually consist of a catalyst (solid) suspended in a liquid, through which a gas is bubbled. They can operate in either semi-batch or continuous mode.

The slurry phase Fischer-Tropsch reactor pictured below is used in a gas-to-liquid (GTL) process plant to convert natural gas into GTL diesel.

Equipment Design

The movie below shows the basic operation of a slurry reactor. Inside the reactor are catalyst pellets suspended in a liquid. Gas reactant is bubbled into the reactor. The gas is absorbed into the liquid from the bubble surface. The absorbed gas then diffuses through the liquid to the catalyst surface, at which point it diffuses into the catalyst pellet and the reaction takes place.

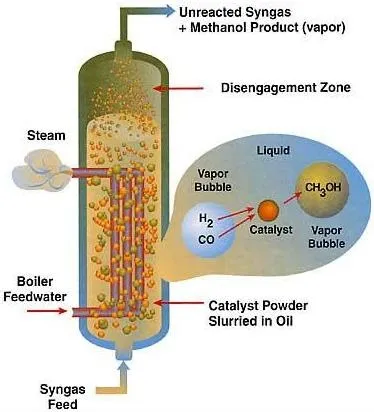

The diagram below shows the synthesis of methanol in a slurry batch reactor. Syngas enters at the bottom of the reactor into heated mineral oil. The gas then reacts with the assistance of suspended catalyst to form the methanol product. Unreacted gas and methanol vapor exit though the top of the reactor. Once out of the reactor, the methanol is condensed to a liquid.

Usage Examples

Slurry reactors are most frequently used when a liquid reactant must be contacted with a solid catalyst, and when a reaction has a high heat of reaction. They may be used in such applications as hydrogenation, oxidation, hydroformation, and ethynylation. The reactor shown below is a slurry phase hydrogenation reactor.

High molecular weight carbons are produced in slurry reactors by running CO and H 2 through wax.

Advantages

· Good temperature control.

· Good heat recovery.

· Constant overall catalytic activity maintained easily by addition of small amount of catalyst.

· Useful for catalysts that can't be pelletized.

· Large heat capacity of reactor acts as a safety feature against explosions.

Disadvantages

· Reactor may plug up.

· Uncertainties in design process.

· Finding suitable liquids may be difficult.

· Higher ratio of liquid to catalyst than in other reactors.