Gravity meters

Basically, there are two main gravity types – the absolute and relative gravity meters. In geophysical prospection solely the former are used. They measure relative gravity – the gravity changes, not the value of gravity itself. If we want to measure the absolute value of gravity we must use some point with already known gravity value and start our measurements there. Then, by adding the measured differences, we know the absolute values of gravity on all our points. However, this is needed only in large scale mapping, where we want to add our data to already existing grid.

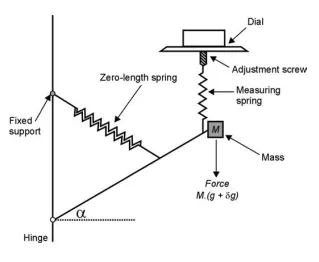

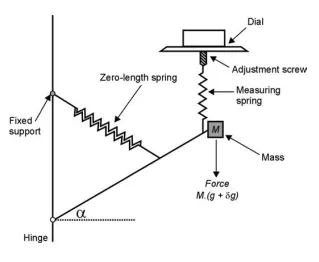

The gravity meters used for the geophysical prospection are the astatic gravity meters (Fig. 2.6), where the mass is hold by the measuring spring. Elongation of this spring is proportional to the gravity force pulling the mass. The older models of gravity meters used a dial to raise or lower the measuring spring to place the mass to a standard position. In modern gravimeters this is done automatically. From the sketch it is clear that the springs used in the meters must be extremely thin and sensitive.

There are two main types of the springs – steel springs in the LaCoste-Romberg gravity meters and quartz springs in the others. Currently, there are two manufacturers of the prospection gravity meters – the Scintrex with quartz springs and Burris, resembling the old LaCoste-Romberg and using the steel springs. To minimise effects of thermal changes, the spring is in thermally insulated chamber (vacuum chamber), the new models are also equiooed with an additional heater to keep the internal temperature as stable as possible.

Hence, removing batteries from the gravity meter leads to change in the inner temperature resulting in unstable and unreliable readings due to changes of mechanical properties of the measuring spring. When the gravimeter is without the power supply for a long time (several hours) it could take as long as 48 hours before realiable readings could be done again.