Power Systems

Drilling rigs, and their support vessels in the case of barge and floating vessels, have high power requirements. Some of the equipment requiring power includes the drawworks, mud pumps, rotary system, and life-support system. The power loading may be continuous or intermittent.

Fig, 16-17 Semi submersible drilling rig (Courtesy Western Oceanic Inc.)

The power system on a drilling rig usually consists of a prime mover as the source of raw power and some means to transmit the raw power to the end-use equipment. The prime movers used in the current drilling industry are diesel engines. Steam boilers are rarely used in present operations due to the difficulty in transporting the boilers and the fact that greater widespread knowledge of diesel units exists among crewmen.

Raw power is transmitted via one of the following systems:

* mechanical drive

• direct current (DC) generator and motor

• alternating current (AC), silicon controlled rcctificr (SCR), direct current (DC) motor

The most widely used system on new rigs or large marine rigs is the AC-SCR system.

The mechanical horsepower requirements for the prime movers must be determined from an evaluation of the loads and the overall system efficiency:

efficiency where the efficiency is less than 1.0. Although Eq. 16.1 is straightforward, it is somewhat difficult to implement due to problems in establishing the load and efficiency factor.

The efficiency factor (E) describes the power losses from the prime movers to the end-use equipment. It can be calculated from Eq. 16.2:

energy output where output is from the prime mover and input is the amount remaining for actual usage after some losses. The system losses result from friction, gears, and belt and line losses. The efficiency factors range from 0-1. Some drilling personnel assume that efficiency factors for oil-well drilling machinery are 0.98 per shaft and chain. The system efficiency is computed as (0.98)", where n is the number of shafts and chains. If more than one engine is used, an average value is calculated.

The mechanical horsepower requirements must be modified for harsh temperature environments or altitudes. According to API Standard 7B-11C (formerly API Standard 8B), approximate conversions for altitude and temperature of naturally aspirated engines may be made as follows:

• deduct 3% of the standard brake horsepower for each 1,000-ft rise in altitude above sea level

• deduct 1% of the standard brake horsepower for each 10° rise in temperature above 85°F or add \% for each 10" fall below 85°P

The engine manufacturer should be consulted for specific variances. Example 16.1

A drilling rig is working in an arid climate at an elevation of 3,600 ft. During the day, the peak temperature is 105°F. The minimum temperature (prior to dawn) is 45°F. The rig has three 1,000-hp prime movers. Determine the minimum and maximum horsepower available during any 24-hr period.

Solution:

1. The total available horsepower from the prime movers is 3,000 hp.

2. The loss in horsepower due to altitude is:

x 3,600 ft X 3,000 hp = 324 hp 3,000 hp - 324 hp = 2,676 hp

3. The minimum horsepower will occur at the maximum temperature:

4. Conversely, the maximum horsepower will occur at the minimum temperature:

10 r

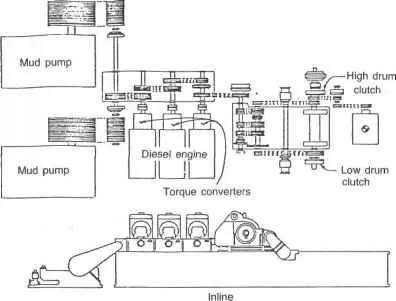

Mechanical Drive Systems. Most early drilling rigs used a mechanical drive system to transmit power from the engines to the operating equipment such as the drawworks and pumps. The drive system consists of gears, chains, and belts (Fig. 16—18). The compound device attached to the engine shafts combines the output of two engines.

Torque converters are attached to the shafts to increase the range of output rpm's and also to improve engine life by absorbing equipment-induced power train shock loads. Efficiency drops off at high torques, but the converter has a useful range of approximately 2:1 multiplication at efficiency factors of 0.75— 0.85. The chief advantage of the converter is the ability to accelerate loads rapidly and give reasonable constant horsepower output over the most efficient 2: 1 speed range.

The weaknesses of the mechanical drive systems are as follows:

• shock loading to the engine

• inability to produce high torque at low engine rpm's, which becomes a compounded problem as higher work loads continue to decrease engine rpm's

• difficulty in providing low torque output due to minimum engine idle speeds and gear ratios

• power loss through the gears and chains

Fig. 16-18 Typical mechanical rig hookup (Courtesy World Oil)

Notwithstanding these acknowledged weaknesses, the mechanical drive system has provided years of beneficial service to the drilling industry and will continue to be used on many land rigs.

Example 16.2

A drilling rig with a mechanical drive system has the following configuration in transmitting power to the drawworks:

No. chains 3 45

Total elements 7 9 11

Assume the torque converter has an efficiency of 0.75 and that efficiencies for each shaft and chain are 0.98. If a drilling design specification requires that a 500,000-lb hook load be hoisted at a rate of 93 ft/min, compute the minimum acceptable input horsepower for the engines. Neglect the traveling block efficiencies.

Solution:

1. From Eq. 16.3, compute the required horsepower at the drawworks:

HP _ force x rate

where force is in lb

= 1,409 hp, drawworks

2. The combined average system efficiency from the drawworks to the converter is:

Engine #1 Engine #2 Engine #3 E = 1(0.98)7 + (0.98)" 4- (0.98)"J/3 - [(0.868) -I- (0.834) + (0.801)J/3 = 10-834 (average system efficiency)]

3. Compute the horsepower requirements to the converter:

Where:

HP{: = converter horsepower

4. Calculate the actual engine requirements by accounting for the efficicncy losses in the converters.

The engine horsepower required to lift the hook load of i00,000 lb at 93 ft/min is 2,252 hp, even though only 1,409 hp was required at the draw-works. (Again, remember that traveling block efficiencies were neglected.)

DC Generator-DC Motor. Direct current (DC) motors have been used since the 1950s to drive drilling and thrustcr motors. The early motors were driven by DC generators, which were attached directly to the output shaft of the prime mover (Fig. 16-19). The DC-DC system is still used on some rigs.

Speed control of the drilling machinery was accomplished in the DC-DC system by varying the field current to the DC generator. The precision of speed control was improved by sensing the output DC motor shaft with a tachometer and feeding the data to the generator lield supply for any necessary correction or adjustment to maintain constant speed.

The direct current motor offered several advantages over the mechanical drive system. Since the motors were connectcd to the generators with power cords, it was not necessary to position the generators and prime movers immediately adjacent to the rig, which thus increased safety and decreased the rig's noise level The average efficiency increased from 0,85 to 0.90, The motors were able to service the equipment over a broader range of torque requirements.

AC-SCR Systems. Alternating current-silicon-controlled rectifier systems are used almost exclusively on new electric rig installations. The AC motors offer longer life, lighter weight, less maintenance, and lower cost than a DC motor. The AC-SCR system offers the same advantage as the DC-DC system when compared to the mechanical drive rig.

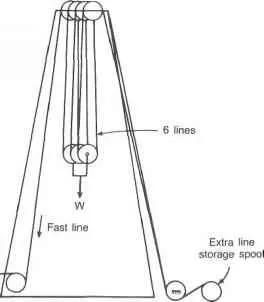

Hoisting Systems. The hoisting system is a vital component of the rig equipment. It provides a means for vertical movement of pipe in the well, i.e., to lower and raise the drillstring and casing. The principal items in the hoisting system are as follows:

* draw works

• crown and traveling blocks

Prime mover

Rig equipment (drawworks, pumps)

DC generator

DC motor

Fig. lfi-19 DC generator-DC motor system

* wireline

* ancillary equipment such as elevators, hooks, and bails

The hoisting system, in conjunction with the circulating equipment, consumes a major portion of the rig's power. Fig. 16-20 illustrates a typical hoisting system.

Drawworks. The draw works is the equipment that uses the energy from the power system to apply a force to the wireline. In practical terms, it reels in the wire rope as the pipe must be lifted. In addition, it allows wireline to be spooled out as the pipe is lowered into the well. The drawworks must have an effective brake system to control the heavy pipe loads and a cooling system to dissipate large amounts of frictional heat generated during braking.

The drawworks drum is grooved to accommodate a certain size wireline. Several layers of the line overlap on the drum. Occasionally, the line becomes damaged due to accelerated wear if it is wrapped improperly on the drum during the reeling process.

Drawworks

Dead-line anchor

Drawworks

Dead-line anchor

Fig. 16—20 Typical hoisting system (Courtesy Petroleum Engineering Drilling & Well Completion)

An effective braking system must be used on the drum. In some eases, 500-ton loads must be decelerated quickly and held in place, A commonly used braking system on mechanical rigs is the hydrodynamic type. The braking is provided by water being impelled in a direction opposite to the rotation of the drum.

Electric rigs often use an electromagnetic (eddy current) brake in addition to a braking action generated by the drive motors on the drawworks. The braking is provided by two opposing magnetic fields. The magnitude of the magnetic fields is dependent on the speed of rotation and the amount of external excitation current. The brake is directly coupled to the drawworks shaft. The electric brake cannot stop the drawworks, but it does take much of the load off the mechanical brake.

Block System. The block-and-tacklc system is the primary link between the drawworks and the pipe or casing, it provides the mechanical advantage to assist in lowering and raising heavy strings of pipe. The equipment can include items such as the crown and traveling blocks, elevators, bails, and heave compensators. (Although the wire rope is an essential part of the block-and-tacklc system, it will be treated separately in this text.)

API Specification 8A recognizes the maximum load rating in tons (2,000-1b units) as follows:

The maximum load rating may be based on either the tensile strength or the yield strength of the material at the manufacturer's option.

The rig must be evaluated with respect to the block-and-tackle system to ensure that it meets the designed safety requirements. Specifications for safety factors are as follows:

Calculated Load Tensile Strength

5 10 15

40 65 100 150

250 350 500 650 750

Rating, tons 0-150

Design Safety Factor 4.00

151-500 501 and over

where R is the calculated load rating in 2,000-lb tons for Eq. 16.5. The maximum load rating of the pipe must be calculated before applying the safety factor and evaluating the equipment rating.