Jet Optimization and Planning

For many years, engineers have known that hydraulics play an Important role in cleaning the face of the formation so that a bit can drill faster. This first became evident when larger pumps increased the drill rate because more mud was being pumped through the large throat of the regular circulation bit. Jet bits were developed to improve on the jetting action of the high mud velocities at the bit. In addition, features such as extended nozzles and varying the number of nozzles were shown to affect drill rate.

Much speculation has been made with respect to the role that hydraulics plays in cuttings removal. For example, do high impact forces clean the hole more effectively than maximum jet velocities? The key point in this speculation is the attempt to develop the "perfect" cleaning mechanism such that a drilled rock fragment is removed, virtually instantaneously, after it is drilled. As yet, industry personnel do not agree on the perfect cleaning technique.

Many attempts have been made to optimize certain bit hydraulics variables to cause perfect cleaning. The variables most commonly optimized are impact force, hydraulic horsepower, and jet velocity. In some cases, any of these variables, when optimized, will clean the hole, whereas in other cases one is more effective than the others. In some cases, none are efficient.

Impact Force, Laboratory and field studies have shown that cross flow beneath the face of the hit is the most effective parameter in hole cleaning. Cross flow is maximum when impact force is maximum.

To optimize hydraulics, the pressure relationships throughout the well must be defined. The total pump pressure (Pp) is equal to the sum of all friction pressures (PF) and the bit pressure drop (PB):

In addition, by observing that PF is proportional to the velocity:

PFctVM (18.46)

Where:

M = flow exponent, usually taken as 1.75 It can be said that:

where C is a constant representing mud properties and wellbore geometry. Rearranging Eq. 18.45 and substituting Eq, 18,47:

Jet impact force was defined previously as follows:

By substituting Eq. 18,48 into Eq. 18.44, the following expression is established:

Or, combining terms:

Using calculus, Eq. 18.50 can be maximized and resolved into Eq. 18.51;

" MT2

Realizing that M is approximately 2, the equation reduces to 0.5 Pp, which is the familiar 50% of pump pressure expended at the bit for optimum impact conditions.

Hydraulic Horsepower, The hydraulic horsepower equation can be optimized in a similar manner, resulting in the following equations:

Eq. 18.53 is developed from 18.52 if M is set equal to 2 so that P, = lAPP.

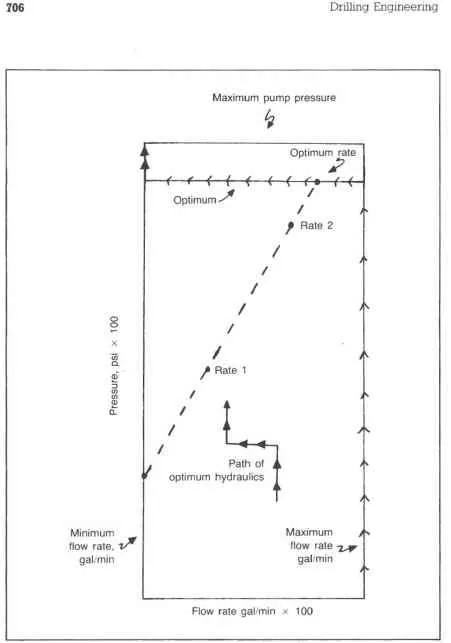

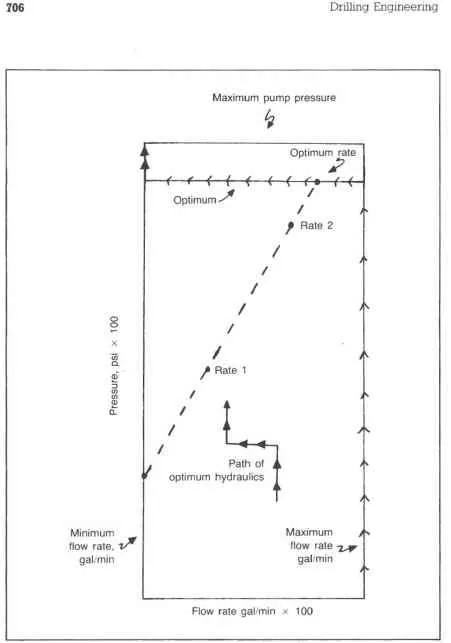

Graphical Method. The most convenient method for selecting proper jet sizes for bit hydraulics optimization is the graphical approach shown in Fig. 18-10. The maximum possible flow rate is based on pump horsepower and pressure limitations. The minimum flow rate is based on acceptable annular velocities for cuttings removal or minimum pumping rates from mechanical restrictions. These two lines are connected by the optimum friction pressure losses desired, usually 50% for impact force or 33% for hydraulic horsepower criteria. The most accurate method is to determine M from two flow rates on the given well and compute the optimum friction pressures using Eqs. 18.51 and 18.52.

After the graph is constructed, plot the two friction pressures resulting from the test rates, determined by subtracting the computed bit drop from the pump pressure. Draw a line through the two points until it intersects the path of optimum hydraulics. The intersection point determines the desired flow rate,

Fig. 18-10 Graphical approach for hit hydraulics optimization