DRILLING AND DRILL RIGS

Once the well site has been selected and all of the legal documents obtained, drilling can only begin after the site has been prepared, ground leveled, roads built (such as in a swamp area) where needed, and a derrick erected and other equipment that comprises the drill rig put in place. Sometimes a water well must be drilled before the oil well can be drilled in order to obtain sufficient water for mixing drilling mud (lubricant).

Most drill rigs are of the rotary rig type. Today's rotary drill rig consists of multiple engines (gas, diesel) that supply power, hoisting equipment that raises and lowers the drill string (drill pipe), and rotating equipment that turns the drill string and the drill bit at the bottom of the hole. These engines also drive the circulating equipment that pumps liquids (mud) down the hole to lubricate the drill string and drill bit (rotating in the hole), removes cuttings (loose bits of rock), and controls downhole pressure to prevent blowouts (pressure in reservoir traps may blow up the open hole and ignite causing an explosion).

The conventional drill bit has three movable cones containing teeth made of tungsten carbide steel and sometimes industrial diamonds. The rotating cones (Remember: the entire drill stem rotates in the hole and the drill bit is attached to the end of the drill stem) are the cutting heads. The downward force on the drill bit is the result of the weight of the overhead drill stem (steel pipe, pipe joints called collars) and drilling equipment on the derrick all of which can amount to thousands of pounds. While the bit cuts into the rock at the bottom of the hole, pumps located at the surface are forcing drilling fluids down the hole (lubricates, removes cuttings) through the inside of the drill pipe. This space between the drill pipe and the walls of the hole is called the annulus space. The fluid then flows out the center of the drill bit and is forced back up the outside of the drill pipe onto the surface of the ground where it is cleaned of debris and pumped back down the hole. This is an endless cycle that is maintained as long as the drill bit is turning in the bottom of the hole.

The drilling crew is under the supervision of the Driller (operates the drilling and hoisting equipment). The person who works on a platform high in the derrick is called a Derrickman; this very dangerous job is to handle the upper part of the drill stem as it is raised and lowered out/into the hole. Roughnecks are the workers on the drill floor; their job is to add new pipe joints as the well is drilled. All of these personnel and the entire operation of the drill rig is under the supervision of the Tool Pusher. A typical drill rig will operate 24 hours per day, 7 days per week. It never shuts down for holidays.

When drilling first began, drilling a straight vertical hole was the most desirable. Now days, however, new drilling technology has developed methodologies for directional drilling (deviating from the vertical at some angle) and horizontal drilling (starting with a vertical hole and then deviating at depth to a horizontal hole). A vertical well has the advantage of penetrating more than one reservoir trap, but the disadvantage is that it can pull hydrocarbons from only a small area within the vicinity of the well. Horizontal wells on the other hand, are much more limited in penetrating multiple reservoir traps, but can remove hydrocarbons from greater areas within a given trap. Almost all wells drilled from an offshore platform are of the directional type. Completing the bottom of the well so that it is ready to withdraw hydrocarbons from the subsurface is done in the same manner regardless of whether it is a convention vertical hole or a horizontal hole. This is because moving the platform to a new site is too costly.

A drilling operation produces waste material that includes drilling mud, rock cuttings, and salt water brine (highly concentrated salt water generally about 80,000 PPM Sodium) which flows out of a reservoir trap and up the well to the surface. These materials must be disposed of properly. The reserve pond is often dug to temporarily hold the brine and drilling mud, but environmental regulations require such ponds be lined with materials that will prevent the contaminants from entering into the subsurface. Often the brines are pumped back into the hole being drilled. In any event, neither the drill mud nor the salt water brine is allowed to remain at the drilling site. All waste materials must be removed off site and sent to a properly licensed landfill for disposal.

DRILLING AND DRILL RIGS

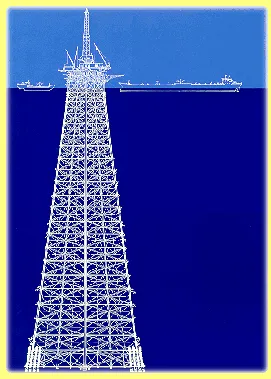

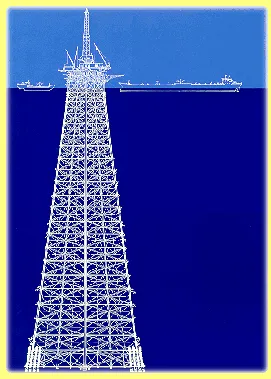

The first offshore exploration was in the Gulf of Mexico in the 1930's; it was a derrick built on a barge that was towed offshore behind a tug boat where it was submerged to rest on the sea floor. The first offshore platform was built in 1947 in water that was 23 feet deep. Offshore rigs have progressed a long way in 70 years, but all are either floaters or sinkers. Floaters refer to semi-submersibles and drill ships. They are used in deep water where it is not practical to anchor to the sea floor. Semi-submersibles may be self propelled, but all have a steel superstructure that is part above and part below water level. The semi has a deck that is mounted on large columns connected to pontoons that are able to raise the structure when it's being moved or lower it when it is drilling a hole. Ballast is added when stability is a required by adding water into the pontoons.

In water less than about 300 feet deep, exploration is performed using self-elevated, or jack-up rigs. The derrick and support equipment are built onto a large barge that is towed out to sea. When the exact location is reached, the barge is held in position while steel legs are lower (jacked down) to the sea floor. Then the barge portion of the rig is jacked up the steel legs so that the entire platform including the barge portion is now above the surface of the ocean.

The first offshore platform was built in 1947 in water that was 23 feet deep. But technology was evolving at a rapid pace. It was thought that platforms anchored to the sea floor in water >300 feet deep was impractical. But in today's world, it is now possible to construct offshore platforms taller than most of the world's skyscrapers and yet be anchored to the sea floor in more than 1,300 feet of water. This illustration graphically depicts the engineering advances that made possible from 1947 to 1988.