What is Directional Drilling?

Most wells drilled for water, oil, natural gas, information or other subsurface objectives are vertical wells - drilled straight down into the earth. However, drilling at an angle other than vertical can obtain information, hit targets, and stimulate reservoirs in ways that cannot be achieved with a vertical well. In these cases, an ability to accurately steer the well in directions and angles that depart from the vertical is a valuable ability.

When directional drilling is combined with hydraulic fracturing, some rock units which were unproductive when drilled vertically can become fantastic producers of oil or natural gas. Examples are the Marcellus Shale of the Appalachian Basin and the Bakken Formation of North Dakota.

(B) Drain a large area from one drill pad |

Minimize footprint: One drilling pad can be used to drill a number of wells. This reduces the footprint of drilling operations. In 2010 the University of Texas at Arlington drilled 22 wells on a single platform. These wells are draining the natural gas from about 1100 acres beneath the campus. Over a 25-year lifetime, the wells are expected to produce a total of 110 billion cubic feet of natural gas. The alternative would be to drill many wells, each requiring a drilling pad, pond, access road and gathering line.

Why Drill Wells That Are Non-Vertical?

Directional and horizontal drilling have been used to reach targets beneath adjacent lands, reduce the footprint of gas field development, increase the length of the "pay zone" in a well, deliberately intersect fractures, construct relief wells, and install utility service beneath lands where excavation is impossible or extremely expensive.

Below is a list of six reasons for drilling non-vertical wells. They are graphically illustrated by the six drawings on this page.

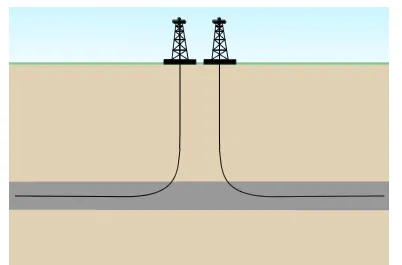

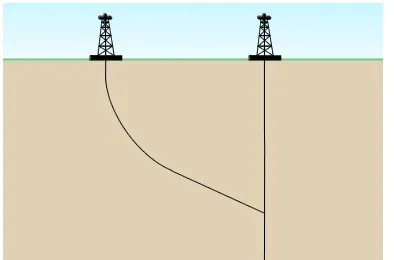

A) Hit targets that cannot be reached by vertical drilling.

Sometimes a reservoir is located under a city or a park where drilling is impossible or forbidden. This reservoir might still be tapped if the drilling pad is located on the edge of the city or park and the well is drilled at an angle that will intersect the reservoir.

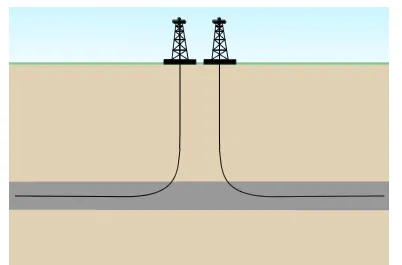

B) Drain a broad area from a single drilling pad.

This method has been used to reduce the surface footprint of a drilling operation. In 2010, the University of Texas at Arlington was featured in the news for drilling 22 wells on a single drill pad that will drain natural gas from 1100 acres beneath the campus. Over a 25-year lifetime, the wells are expected to produce a total of 110 billion cubic feet of gas. This method significantly reduced the footprint of natural gas development within the campus area.

(C) Increase the length of the "pay zone" |

Maximize pay zone: If a vertical well is drilled through a 50-foot-thick reservoir rock, then natural gas or oil can seep into the well through 50 linear feet of "pay zone." However, if the well is turned to horizontal (or the same inclination as the rock unit) and drilled within that rock unit, then the distance of penetration within the pay zone can be much greater. Some horizontal wells have over one mile of pay zone penetration.

(D) Improved production in a fractured reservoir |

Fractured reservoir: Some reservoirs have most of their pore spaces in the form of fractures. Successful wells must penetrate fractures to have a flow of natural gas into the well. In many geographic areas there is a dominant fracture direction along which most of the fractures are aligned. If the well is drilled perpendicular to the plane of these fractures, then a maximum number of fractures will be penetrated.

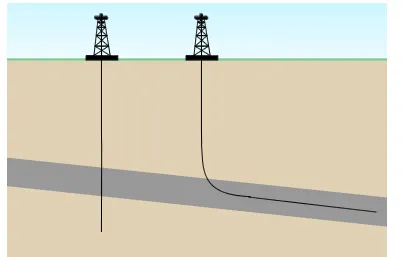

C) Increase the length of the "pay zone" within the target rock unit.

If a rock unit is fifty feet thick, a vertical well drilled through it would have a pay zone that is fifty feet in length. However, if the well is turned and drilled horizontally through the rock unit for five thousand feet, then that single well will have a pay zone that is five thousand feet long - this will usually result in a significant productivity increase for the well. When combined with hydraulic fracturing, horizontal drilling can convert unproductive shales into fantastic reservoir rocks.

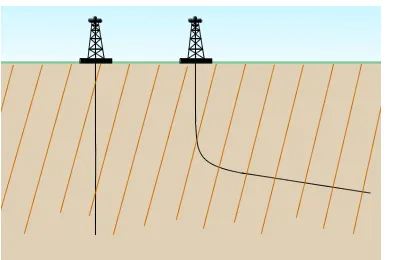

D) Improve the productivity of wells in a fractured reservoir.

This is done by drilling in a direction that intersects a maximum number of fractures. The drilling direction will normally be at right angles to the dominant fracture direction. Geothermal fields in granite bedrock usually get nearly all of their water exchange from fractures. Drilling at right angles to the dominant fracture direction will drive the well through a maximum number of fractures.

E) Seal or relieve pressure in an "out-of-control" well.

If a well is out of control, a "relief well" can be drilled to intersect it. The intersecting well can be used to seal the original well or to relieve pressure in the out-of-control well.

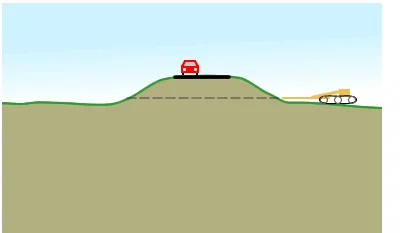

F) Install underground utilities where excavation is not possible.

Horizontal drilling has been used to install gas and electric lines that must cross a river, cross a road, or travel under a city.

(E) "Relief well" for an "out-of-control" well |

Relief well: If a well has a problem and begins to flow out of control, it must be sealed at depth or the pressure must be relieved. In this situation a "relief well" can be drilled from a nearby site. The relief well will be a directionally drilled well that intersects the bore of the problem well to drain off some of the pressure or to plug the well by pumping cement into the bore.

Rock Units that Benefit Most from Horizontal Drilling

Vertical wells can effectively drain rock units that have a very high permeability. Fluids in those rock units can flow quickly and efficiently into a well over long distances.

However, where permeability is very low, fluids move very slowly through the rock and do not travel long distances to reach a well bore. Horizontal drilling can increase the productivity in low-permeability rocks by bringing the well bore much closer to the source of the fluid.

(F) Installation of underground utilities |

Utility line: Utility service lines such as those delivering electricity, water, or natural gas are sometimes installed by directional drilling. This method is used when they must cross a road where excavation would disrupt traffic, cross a river where excavation is impossible, or transverse a community where surface installation by excavation would be extremely expensive and disrupting.

Horizontal Drilling and Hydraulic Fracturing in Shales

Perhaps the most important role that horizontal drilling has played is in development of the natural gas shale plays. These low-permeability rock units contain significant amounts of gas and are present beneath very large parts of North America.

The Barnett Shale of Texas, the Fayetteville Shale of Arkansas, the Haynesville Shale of Louisiana and Texas, and the Marcellus Shale of the Appalachian Basin are examples. In these rock units the challenge is not "finding" the reservoir; the challenge is recovering the gas from very tiny pore spaces in a low-permeability rock unit.

To stimulate the productivity of wells in organic-rich shales, companies drill horizontally through the rock unit and then use hydraulic fracturing to produce artificial permeability that is propped open by frac sand. Done together, horizontal drilling and hydraulic fracturing can make a productive well where a vertical well would have produced only a small amount of gas.

Drilling Methodology

Most horizontal wells begin at the surface as a vertical well. Drilling progresses until the drill bit is a few hundred feet above the target rock unit. At that point the pipe is pulled from the well and a hydraulic motor is attached between the drill bit and the drill pipe.

The hydraulic motor is powered by a flow of drilling mud down the drill pipe. It can rotate the drill bit without rotating the entire length of drill pipe between the bit and the surface. This allows the bit to drill a path that deviates from the orientation of the drill pipe.

After the motor is installed, the bit and pipe are lowered back down the well, and the bit drills a path that steers the well bore from vertical to horizontal over a distance of a few hundred feet. Once the well has been steered to the proper angle, straight-ahead drilling resumes and the well follows the target rock unit. Keeping the well in a thin rock unit requires careful navigation. Downhole instruments are used to determine the azimuth and orientation of the drilling. This information is used to steer the drill bit.

Horizontal drilling is expensive. When combined with hydraulic fracturing, a well can cost up to three times as much per foot as drilling a vertical well. The extra cost is usually recovered by increased production from the well. These methods can multiply the yield of natural gas or oil from a well. Many profitable wells would be failures without these methods.