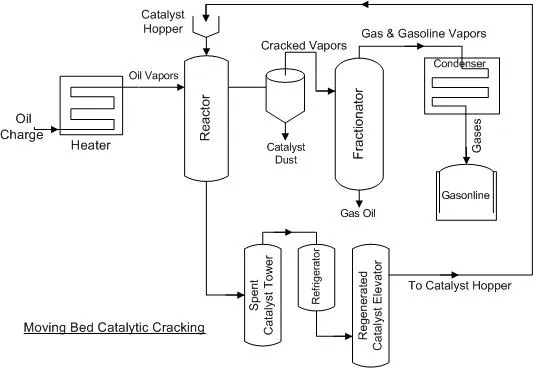

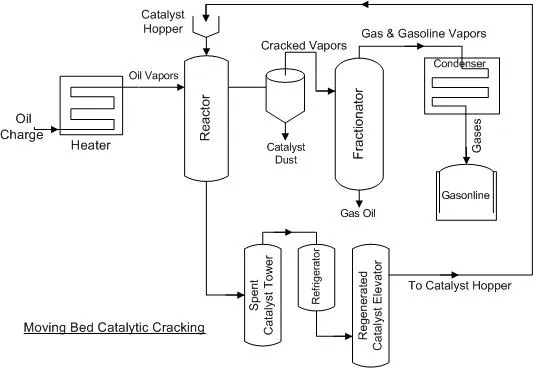

Moving Bed Catalytic Cracking Process

The moving bed catalytic cracking method is described in the following diagram.

Heated oil vapors go up in the reactor and catalyst comes down through the hopper which is the significance in the moving bed catalytic cracking process. After the cracking of vapors the spent catalyst is removed from the bottom. It is regenerated and sent again to the catalyst hopper through the elevators. The cracked vapors after the separation of dust separated go to the fractionator where gas oil is separated from vapors of gas and gasoline. Gas oil is with drawn from the bottom. The gas and the gasoline vapors are condensed in the condenser and are separated.

Other methods of synthesis of gasoline are by polymerization, alkylation, Fischer-Tropsch method and liquefaction of coal or hydrogenation of coal.

Normally the gases obtained from the cracking of petroleum are ethylene, propene, butene and saturated hydrocarbons like methane, ethane, propane and butane. Polymerization also classified by catalysis to obtain motor fuel.