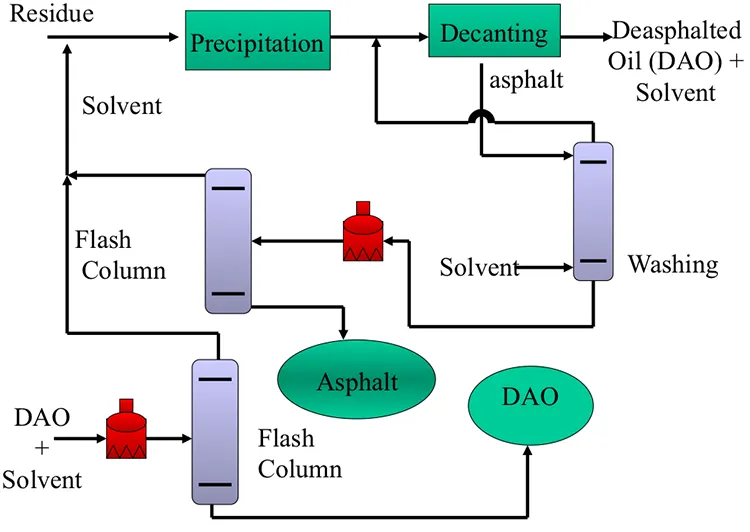

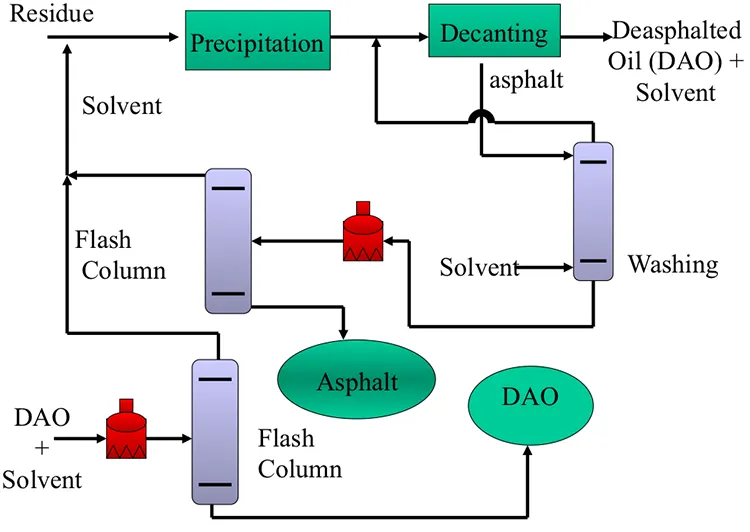

Simplified Flow Diagram of a Deasphalting Process

Simplified Flow Diagram of a Deasphalting Process

Figure 5.9 shows a simplified flow diagram of a propane deasphalting process. See a more detailed flow diagram in your textbook along with a description of the operating conditions in the commercial process. As the first step in deasphalting, residue (feedstock) is mixed with four to eight times the volume of liquid propane. Heavier residua require a higher solvent to residue (S/R ) ratio for effective separation of asphalt. Following the precipitation of asphalt, DAO and asphalt are separated, and each stream is purified and flashed to recover and recycle the propane solvent, as shown in Figure 5.9.

Figure 5.9. A deasphalting process

The four-unit operations of deasphalting illustrated in the process flow diagram are:

1. Flocculation (& precipitation) of asphaltenes

2. Asphalt decanting - separation

3. Asphalt washing - to remove entrained oil

4. Solvent recovery and recycle