Petroleum Production

Production phase aims to the recovery of the reservoir fluids to surface followed by their processing.

All production and maintenance activities are carried out to meet strict safety and environmental policies and procedures.

During the production phase it is necessary to:

The production phase begins with the first commercial volumes of hydrocarbons (“first oil”) flowing through the wellhead – this establishes a fundamental turning point from a cash flow stand point.

From now on, cash is generated and can be used to pay back the previous investments, or may be made available for new projects (ex. new exploration…).

The development and production planning are based on the expected production profile which are strongly dependent on the reservoir drive mechanism.

It is the forecasted production profile that will determine the size of facilities required to treat and disposes the fluids and the number and phasing of wells to be drilled.

A typical production profile is made up by three phases:

Typical field production profile

The mode of operations and maintenance required are specified in the field development plan.

It is necessary to deliver product at the required rate and quality and therefore, the product quality specification and contract terms guide the activities of the production operations.

The “product” quality is not limited to oil and gas, but also to other fluid/byproduct streams.

The process and facilities engineers design

The processing plants are designed to treat specific types of hydrocarbon according to their characteristics.

The recovered fluids are processed for technical, safety and economic reasons

By processing the produced fluids, it is possible to

Gas processing may include

Crude oil processing may include

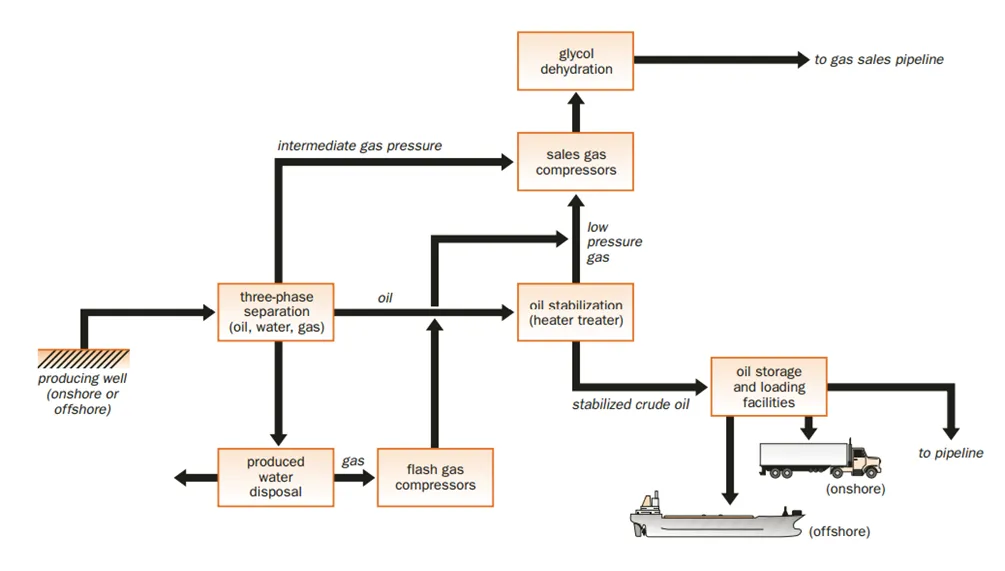

Typical Crude Oil Processing

During production, monitoring and control of the production processes is performed by a combination of instrumentation and control equipment which

Waste disposal is another important aspect of the production process and it should cover all effluent streams.

The treatment of these products and waste is discussed jointly with the Environment department, process and facilities engineers.

An oil and gas processing plant include the utilities systems which do not take part to the processes but support production operations

Utility systems include

The necessary control and monitoring of processing operations is managed from the control room, which is a dedicated structure where operators perform plant operations monitor and control using sophisticated and automatic control systems in a safe and efficient manner.

Operators in a processing plant control room