Petrochemical Industry in India (With Statistics)

The Major Products of Petrochemical Industry:

The original raw material of the industry is crude oil. Ready and easy availability of crude oil is pre-requisite of the establishment of petrochemical industry.

The derivatives of the crude oil are:

I. a. naphtha or gas cracker plants produce ethylene, propylene etc. b. Aromatic complexes to produce: Benzene, Toluene and xylene.

II. a. Polymers, styrene etc.

b. Synthetic fibre

c. Elastomers like butyl rubber, SBR, PBR etc.

d. Surfactant intermediates

e. Other petrochemicals like solvents etc.

III. Synthetic fibres.

IV. Polymers & plastic materials etc.

Growth and Distribution:

At its initial years of growth, Central Government undertakings namely Indian oil, gas authority of India (Gail), Indian Petrochemical (IPCL) took major initiative to promote petrochemical industry. These companies along with private players like Reliance, Oswal agro invested huge amount of money in the development of the industry.

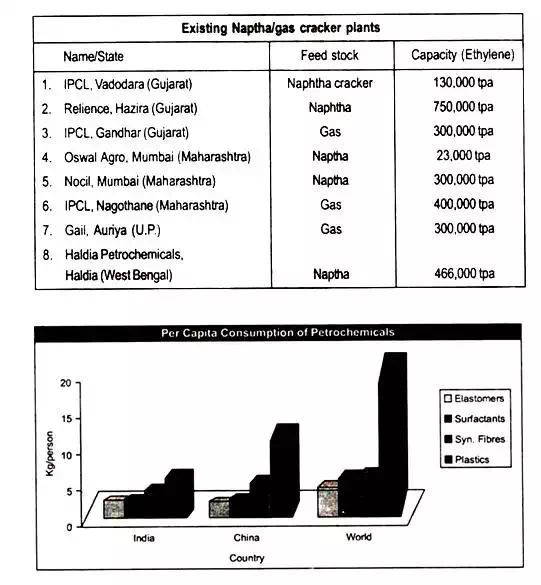

Altogether nine petrochemical plants are now in operative, of which four are located at Gujarat and three are located within Maharashtra. One each are situated in U.P. and West Bengal respectively.

Petrochemical industry is capital intensive and technology intensive as well. Initial investment may exceed 50,000 crore. It should have capacity above break-even point. Otherwise the production cost will not be able face competition.

India Government in its policy had declared several tariff and duty exemptions in order to give incentives for expansion of petrochemical industry as a whole. Government is also eager to attract foreign direct investment (FDI) in petrochemical sector. To attract foreign direct investment, Government of India has relaxed some licensing policies.

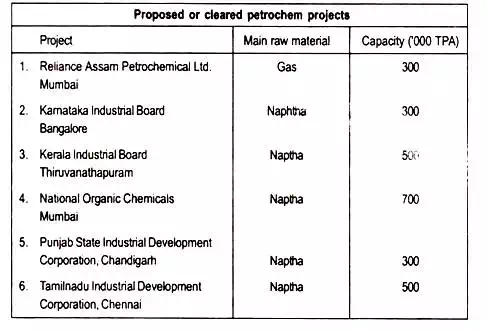

Some of the proposed projects has already been cleared by government are:

Present Position:

Indian petrochemical industry is currently achieved a growth rate of 14 to 15% per annum. Despite this significant growth, per capita consumption of petrochemical goods in India is still lagging far behind than China and global consumption.

According to economic survey 2004-05 production of major petrochemicals in 2003-04 increased by 6.9% and reached a level of 7,006 thousand tonnes. During 2004-05, production of major petrochemicals is expected to grow by 5% and reach a level of 7,355 thousand tonnes. India is still not self-reliant in plastic and synthetic fibre production. The total consumption of plastic and synthetic fibre as 3.8 million tonnes and 1.65 million tonnes respectively in 2001-02. The increased capacity utilization during IX th five year plan enabled India to produced and marketable surplus of polyethylene and polystyrene. At present eight cracker complexes produced 2.4 million tonnes ethylene. Four aromatic complexes — Bongaigaon Refinery, IPCL and two plants of Reliance produced 1.8 million tonnes.

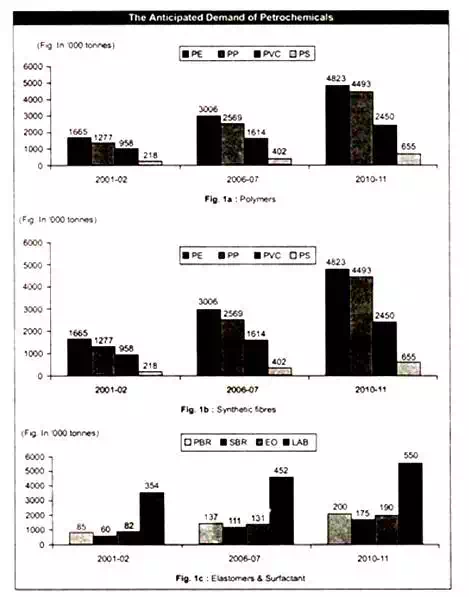

The capacity of polymers, synthetic fibre, elastomers and surfactants intermediate are as follows in 2002:

1. Polymer capacity — 42, 15,000 tonnes/annum.

2. Synthetic fibre capacity — 20, 69,000 tonnes/annum.

3. Elastomers capacity — 1, 45,000 tonnes/annum.

4. Surfactants capacity — 4, 09,000 tonnes/annum.

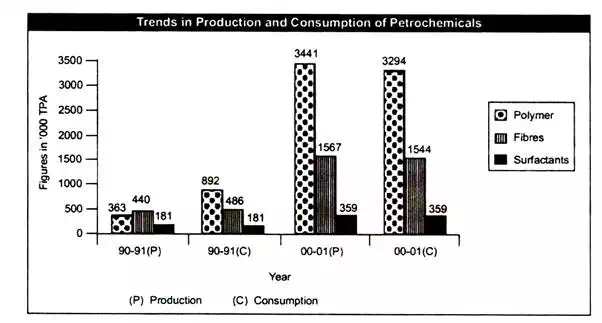

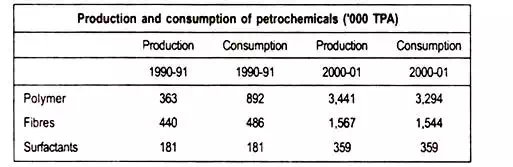

From the production and consumption figures of 1990-91 and 2000-01, it is evidently clear that from a deficient producing country, India has emerged as surplus producing country in the case of polymer. The rest two, i.e., fibres and surfactants production is now at per with consumption.

Future Scope:

Keeping in mind of India’s present industrial growth rate (around 9% each year). Petrochemical industry might register huge growth as government is giving all kinds of incentives, the plastics, fibres and rubber industry may provide fillip to the host of innumerable down steam industries, providing employment directly or indirectly to millions.