Petrochemical

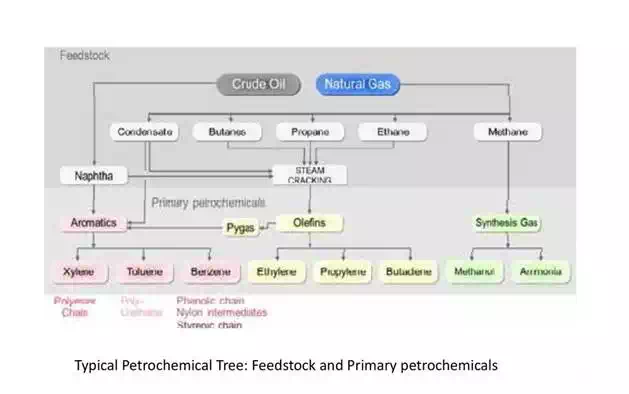

Petrochemicals are chemicals made from petroleum or natural gas. Primary petrochemicals are divided into three groups, depending on their chemical structure:

Olefins include ethylene, propylene, and butadiene. Ethylene and propylene are important sources of industrial chemicals and plastics products. Butadiene is used in making synthetic rubber. Olefins are produced by cracking.

Aromatic petrochemicals include benzene, toluene, and xylenes. Benzene is used in the manufacture of dyes and synthetic detergents. Toluene is used in making explosives. Manufacturers use xylenes in making plastics and synthetic fibers. Aromatics are produced by reforming.

Synthesis gas (SynGas) is a mixture of carbon monoxide and hydrogen, and is used to make the petrochemicals ammonia and methanol. Ammonia is used in making fertilizers and explosives, where methanol serves as a source for other chemicals

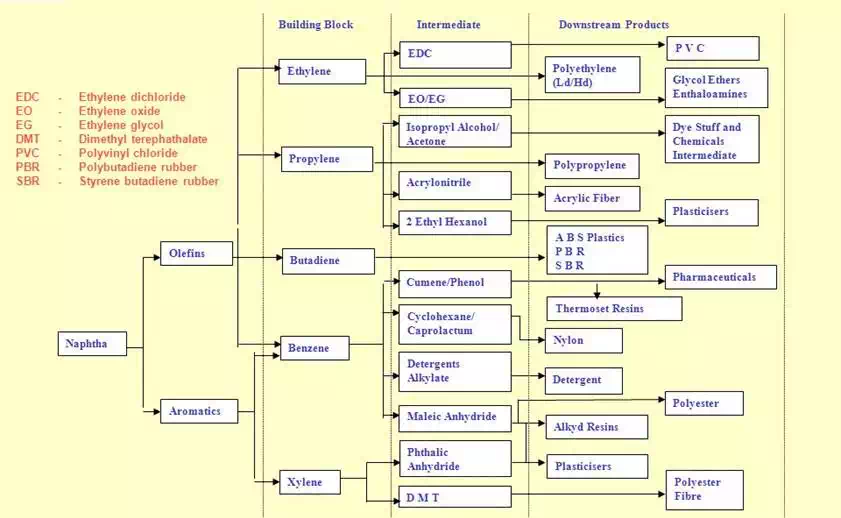

Petrochemical Product Tree

The primary petrochemicals are not end products, but form building blocks for a wide range of materials. Therefore, each primary petrochemical gives name to a chain of reactions leading to those materials. There are almost 200 petrochemicals that can be described this way. There are more processes than end products, as each product may require multiple steps, so an exhaustive list would not fit within this book. Instead, we will focus on the main chains, properties and uses of the most important compounds and a few key processes for this overview.

Many of these processes are based on polymerization, which means that it is based on processes that first form monomers then let these bind together to form polymers as long chains or a three dimensional network. Compounds whose names start with “poly” are generally polymers, but many other trade names, such as nylon which is a generic name for a family of polyamides, are polymers.

Petrochemicals are often made in clusters of plants in the same area. These plants are often operated by separate companies, and this concept is known as integrated manufacturing. Groups of related materials are often used in adjacent manufacturing plants, to use common infrastructure and minimize transport.