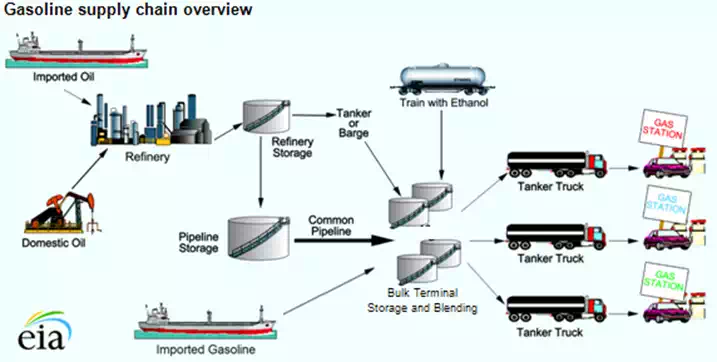

Blending and distribution

After the refining processes, the various fractions are stored in intermediate tanks, then blended into marketable products for loading onto railcars, trucks or ships, and distribution to gas stations or industries. Each product is blended to a specification of up to 25 parameters such as octane rating, energy content, volatility and sulfur content. The task is to achieve the specification (and not exceed, where applicable) with the minimum amount of over-spec “giveaway.” The blending quality is managed with infrared or chromatograph type process analyzers. These can determine the precise fractions of a sample by molecule type.

The standard specification gasoline is therefore standard from company to company in the individual markets, ensuring compatibility with vehicle manufacturer requirements. Also, the terminal operator may be an independent third party or run as co-distribution, so that a terminal in one region distributes for several companies based on the same products in the same tanks.

Each company then seeks to differentiate its product by adding small quantities of unique additives that are marketed to increase engine performance, lifetime, clean combustion and so forth. These additives are added as the product is dispensed to trucks for delivery to that brand gasoline station.

A main task is to ensure the balance of incoming and outgoing products and consolidate with stored volumes. These have to be compensated for temperature, water content (water may be absorbed from air humidity and released at low temperatures as bottom slop in tanks) and vapor loss. Vapor or volatile organic compounds (VOCs), form above the product in fixed roof tanks and when filling up compartments in cars or vessels. VOC loss can be significant for high volatility products like gasoline, and must be recovered and/or handled to reduce emissions and explosive hazard.

The terminal management system tracks batches of product received or dispensed, as well as those eventually received by gasoline stations, airports or other consumers and consolidates with stored volumes. Each operation should be validated against orders, bills of lading and positive identification of trucks, vessels and their operators. In countries where this process is not well managed, losses of product due to theft and other factors can be as high as 15% or more in the distribution operations.

Eventually the main goal is to ensure that orders are met, and stakeholders pay or get paid in the form of VAT, taxes, product, delivery charges, etc.