Compressors, anti-surge and performance

Compressors are used in many parts of the oil and gas process, from upstream production to gas plants, pipelines, LNG and petrochemical plants. The overview given here will therefore be referenced from other sections.

Several types of compressors are used for gas compression, each with different characteristics such as operating power, speed, pressure and volume:

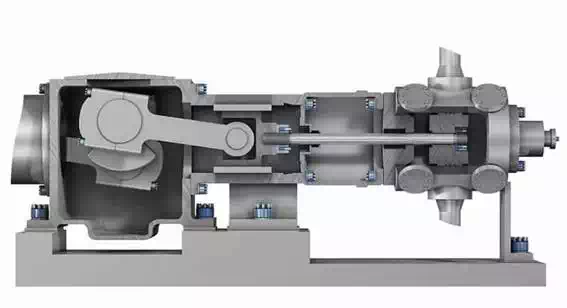

Reciprocating compressors, which use a piston and cylinder design with 2-2 cylinders are built up to about 30 MW power, around 500-1,800 rpm (lower for higher power) with pressure up to 5MPa (500 bars). Used for lower capacity gas compression and high reservoir pressure gas injection.

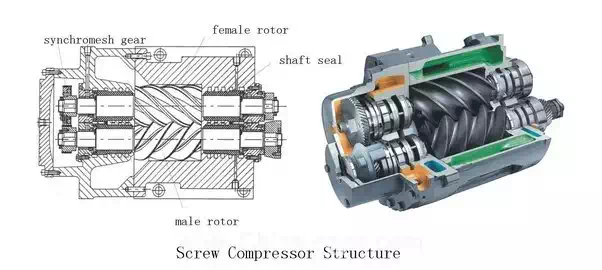

Screw compressors are manufactured up to several MW, synchronous speed (3,000/3,600 rpm) and pressure up to about 2.5 MPa (25 bar). Two counter-rotating screws with matching profiles provide positive displacement and a wide operating range. Typical use is natural gas gathering.

Axial blade and fin type compressors with up to 15 wheels provide high volumes at a relatively low pressure differential (discharge pressure 3-5 times inlet pressure), speeds of 5,000-8,000 rpm, and inlet flows up to 200,000 m3 /hour. Applications include air compressors and cooling compression in LNG plants.

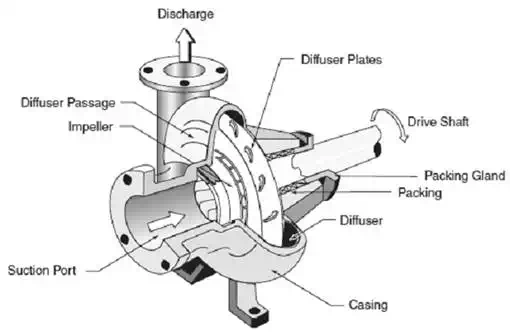

Larger oil and gas installations use centrifugal compressors with 3-10 radial wheels, 6,000–20,000 rpm (highest for small size), up to 80 MW load at discharge pressure of up to 50 bars and inlet volumes of up to 500,000 m3 /hour. Pressure differential up to 10.

Most compressors will not cover the full pressure range efficiently. The lowest pressure is atmospheric, for gas to pipeline, some 3 to 5 MPa (30-50 bar) pressure is used, while reservoir reinjection of gas will typically require 20 MPa (200 bar) and upwards, since there is no liquid in the tubing and the full reservoir pressure must be overcome. Therefore, compression is divided into several stages to improve maintenance and availability. Also due to single unit power limitations, compression is often divided in several parallel trains. This is not the case in this example, since gas is not exported and reinjection can be interrupted during maintenance periods.

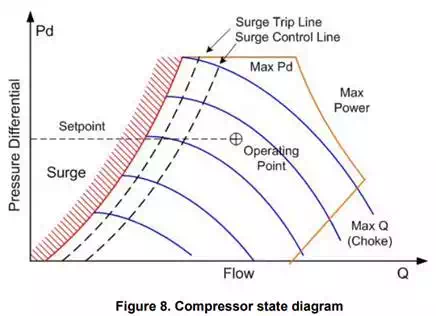

Compressors are driven by gas turbines or electrical motors (for lower power also reciprocating engines, steam turbines are sometimes used if thermal energy is available). Often, several stages in the same train are driven by the same motor or turbine.The main operating parameters for a compressor are the flow and pressure differentials. The product defines the total loading, so there is a ceiling set by the maximum design power. Furthermore, there is a maximum differential pressure (Max Pd) and choke flow (Max Q), the maximum flow that can be achieved. At lower flow, there is a minimum pressure differential and flow before the compressor will "surge" if there is not enough gas to operate.

If variations in flow are expected or differences between common shaft compressors occur, the situation will be handled with recirculation. A high flow, high pressure differential surge control valve will open to let gas from the discharge side back into the suction side. Since this gas is heated, it will also pass through the heat exchanger and scrubber so as not to become overheated by circulation.

The operating characteristics are defined by the manufacturer. In the diagram above, the blue lines mark constant speed lines. The maximum operating limits are set by the orange line as described above. The surge domain is the area to the left of the red surge curve.

The objective of compressor performance control is to keep the operating point close to the optimal set point without violating the constraints by means of control outputs, such as the speed setting. However, gas turbine speed control response is relatively slow and even electric motors are not fast enough, since surge response must be in the 100 ms range. Anti-surge control will protect the compressor from going into surge by operating the surge control valve. The basic strategy is to use distance between operating point and surge line to control the valve with a slower response time, starting at the surge control line. Crossing the surge trip line will cause a fast response opening of the surge valve to protect the compressor.

Operation with recirculation wastes energy (which could result in unnecessary emissions) and produces wear and tear, particularly on the surge valve. Each vendor supplies several variants of compressor control and anti-surge control to optimize performance, based on various corrective and predictive algorithms. Some strategies include:

• Set point adjustment: If rapid variations in load cause surge valve action, the set point will be moved to increase the surge margin.

• Equal margin: The set point is adjusted to allow equal margin to surge between several compressors.

• Model based control: Outside the compressor itself, the main parameter for the surge margin is the total volume from the surge valve to the compressor suction inlet, and the response time for the surge valve flow. A model predictive controller could predict surge conditions and react faster to real situations while preventing unnecessary recirculation.

Since compressors require maintenance and are potentially expensive to replace, several other systems are normally included:

Load management: To balance loading among several compressors in a train and between trains, the compressor control system often includes algorithms for load sharing, load shedding and loading. Compressors are normally purged with inert gas, such as nitrogen during longer shutdowns, e.g., for maintenance. Therefore, startup and shutdown sequences will normally include procedures to introduce and remove the purge gas.

Vibration: Vibration is a good indicator of problems in compressors, and accelerometers are mounted on various parts of the equipment to be logged and analyzed by a vibration monitoring system.

Speed governor: If the compressor is turbine driven, a dedicated speed governor handles the fuel valves and other controls on the turbine to maintain efficiency and control rotational speed. For electrical motors this function is handled by a variable speed drive.

The final function around the compressor itself is lube and seal oil handling. Most compressors have wet seals, which are traps around shafts where oil at high pressure prevents gas from leaking out to atmosphere or other parts of the equipment. Oil is used for lubrication of the high speed bearings. This oil gradually absorbs gas under pressure and may become contaminated. It needs to be filtered and degassed. This happens in smaller reboilers, in much the same way as for the glycol reboilers.