Subsea & Injection wells

Subsea wells

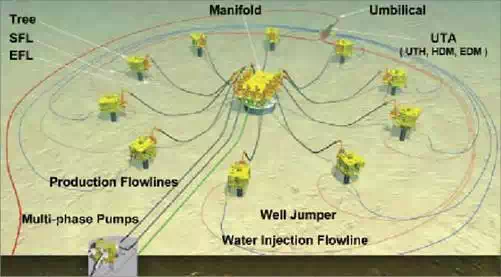

Subsea Wells are essentially the same as dry completion wells. Mechanically, however, they are placed in a subsea structure (template) that allows the wells to be drilled and serviced remotely from the surface, and protected from damage, e.g., from trawlers. The wellhead is placed in a slot in the template where it mates to the outgoing pipeline as well as hydraulic and electric control signals

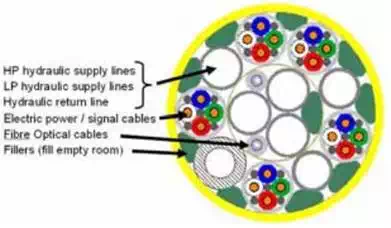

Control is from the surface, where a hydraulic power unit (HPU) provides power to the subsea installation via an umbilical. The umbilical is a composite cable containing tension wires, hydraulic pipes, electrical power, control and communication signals. A control pod with inert gas and/or oil protection contains control electronics, and operates most equipment via hydraulic switches. More complex subsea solutions may contain subsea separation/stabilization and electrical multiphase pumping. This may be necessary if reservoir pressure is low, offset (distance to main facility) is long or there are flow assurance problems so that the gas and liquids will not stably flow to the surface. The product is piped back through pipelines and risers to the surface. The main choke may be located topside.

Injection Wells

Wells are also divided into production and injection wells. The former are for production of oil and gas. Injection wells are drilled to inject gas or water into the reservoir. The purpose of injection is to maintain overall and hydrostatic reservoir pressure and force the oil toward the production wells. When injected water reaches the production well, it is called “injected water breakthrough.” Special logging instruments, often based on radioactive isotopes added to injection water, are used to detect breakthrough. Injection wells are fundamentally the same as production wellheads. The difference is their direction of flow and, therefore, mounting of some directional components, such as the choke.